Post-welding shaping method and welding method for metal target material

A metal target and post-welding technology, which is applied in the post-welding shaping method and welding field of metal targets, can solve problems such as target deformation, unusable metal targets, and complicated processing methods, and achieve improved yield and high industrial application value, the effect of solving the problem of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

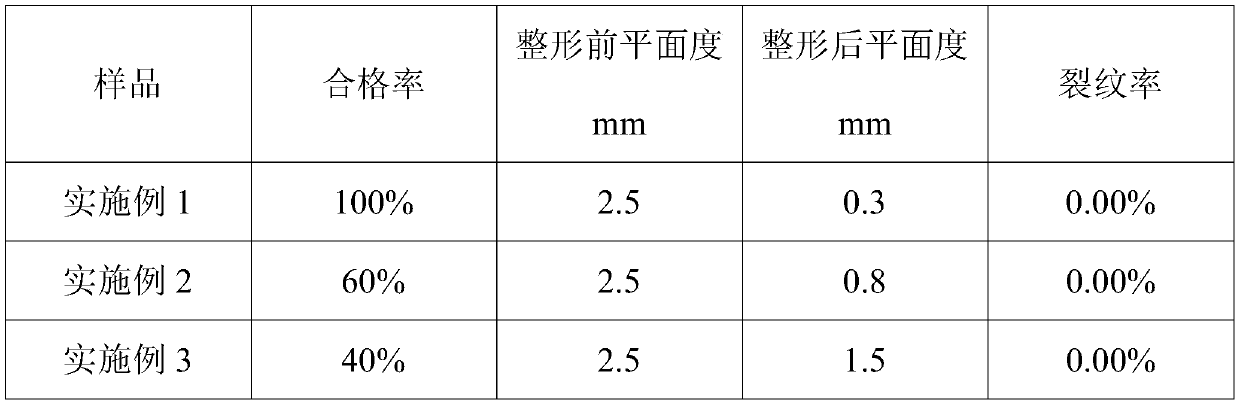

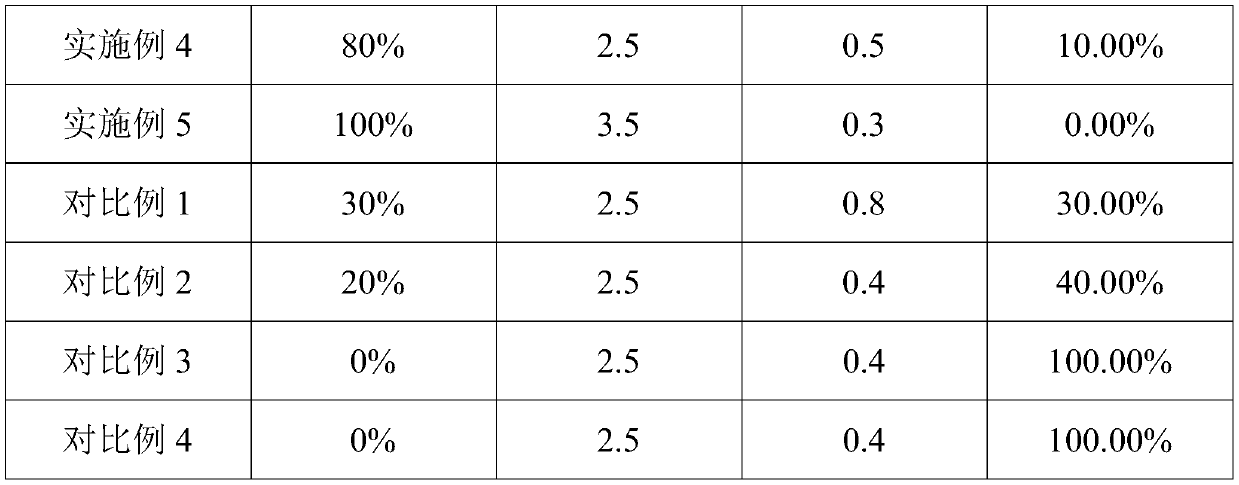

Examples

Embodiment 1

[0088] This embodiment provides a method for shaping a metal target after welding. The method includes the following steps:

[0089] (1) Put the target component A in a heating furnace and keep it at 350℃ for 1h;

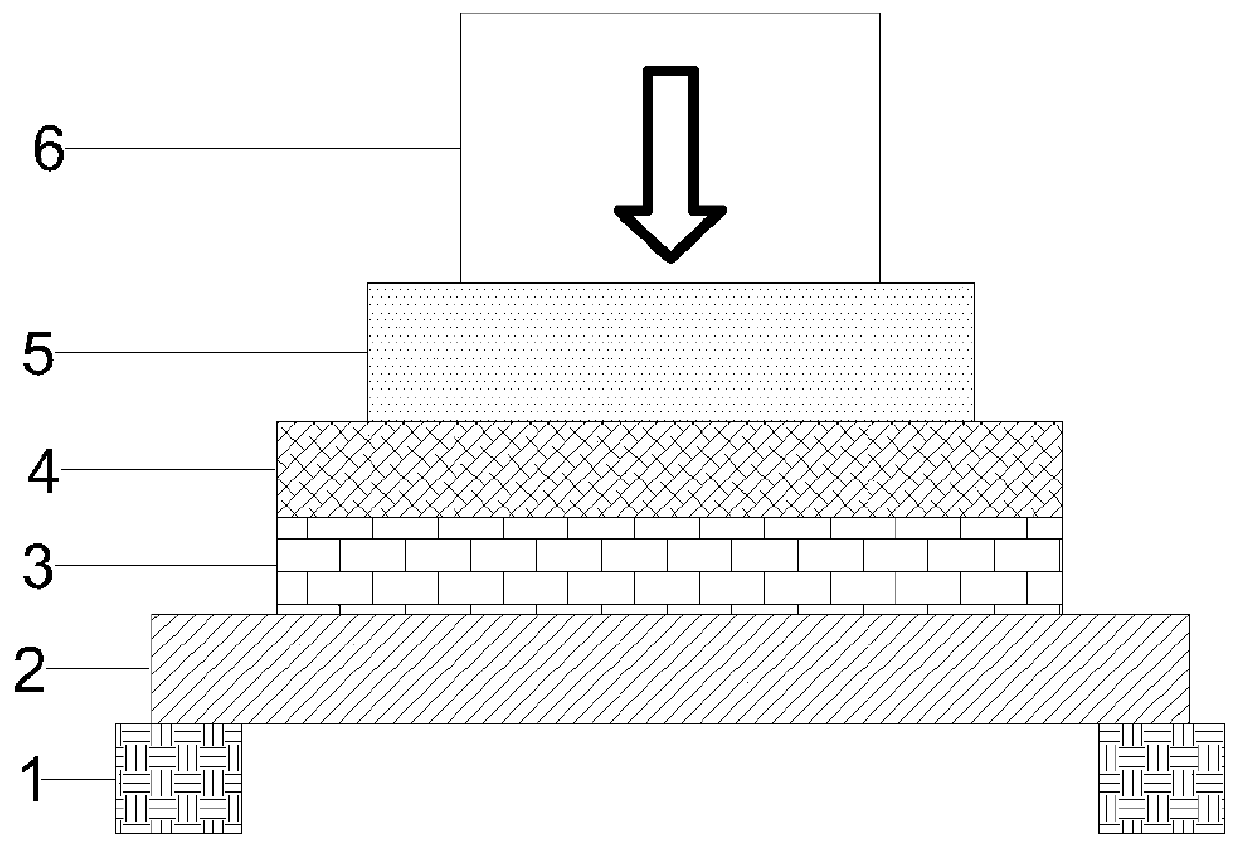

[0090] (2) such as figure 1 As shown, above the target 3 of the target assembly A after heating, a silicone pad 4 with a thickness of 11 mm and a pad 5 with a thickness of 30 mm are arranged in the center on the basis of the target assembly A. A gasket 1 with a thickness of 20mm is centrally arranged under the back plate 2 based on the target assembly A;

[0091] Wherein, the silica gel pad 4 has a hardness of 45HA and a tensile strength of 75kg / cm 2 The diameter of the silicone pad 4 is 410mm, the diameter of the pad 5 is 200mm, and the material is pure aluminum 1060, the inner diameter of the gasket 1 is 430mm, the outer diameter is 470mm, and the material is stainless steel 361;

[0092] (3) The target assembly A is pressurized and shaped by a hydraulic press 6 at a pre...

Embodiment 2

[0094] This embodiment provides a method for shaping a metal target after welding. The method is the same as the embodiment 1 except that the heating operation of step (1) is not performed.

Embodiment 3

[0096] This embodiment provides a method for shaping a metal target after welding. The method except step (2) does not place a gasket with a thickness of 20 mm under the back plate of the target assembly A based on the target assembly A. Same as Example 1, its step (2) is specifically:

[0097] (2) A silicone pad with a thickness of 11 mm and a spacer block with a thickness of 30 mm are arranged in the center above the target of the target assembly A after heating, taking the target assembly A as a reference;

[0098] Wherein, the silicone pad has a hardness of 45HA and a tensile strength of 75kg / cm 2 The diameter of the silicone pad is 410mm, the diameter of the pad is 200mm, and the material is pure aluminum 1060.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com