Method for recovering germanium dioxide from germanium-containing smoke dust

A germanium dioxide and germanium fume technology is applied in the field of metallurgical production of germanium, which can solve the problems of increased cost, low economy and high energy consumption, and achieve the effects of easy filtration, rapid precipitation process and coarse precipitated particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

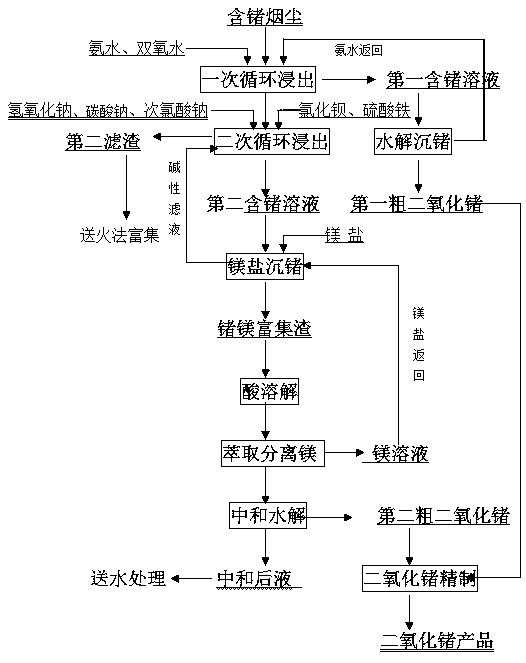

[0049] 1. Combination figure 1 The process route of the present invention is described in detail.

[0050] 1. One cycle leaching:

[0051] (1) Mechanism:

[0052] Germanium leaching process: germanium dioxide is dissolved in ammonia water to form ammonium germanate, and germanium monoxide is oxidized to germanium dioxide.

[0053] GeO+H 2 o 2 = GeO 2 +H 2 o

[0054] GeO 2 +2NH 3 . h 2 O = (NH 4 ) 2 GeO 3 +H 2 o

[0055] During this process, impurity metals such as iron, arsenic, calcium, lead, and silicon in germanium-containing fumes do not participate in the reaction, and only 30-40 wt% of zinc is converted into complex ions. After cyclic leaching, a germanium solution containing more than 10 g / l of germanium can be obtained.

[0056] (2) Treatment process:

[0057] Add germanium-containing fumes, ammonia water, and hydrogen peroxide into the first airtight container, raise the temperature and keep it at 40-80°C, stir and react for 2-5 hours at the same tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com