Aluminum-copper-manganese porous composite material, preparation method and application thereof

A porous composite material, aluminum-copper technology, applied in the direction of additive processing, can solve the problems of poor mechanical properties, shrinkage porosity, complex mold, long processing flow, etc., to inhibit the occurrence of hot cracks, excellent mechanical properties, and avoid hot cracks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The preparation method of aluminum-copper-manganese porous composite material:

[0061] (1) Prepare aluminum-copper-manganese alloy powder. The preparation method of the aluminum-copper-manganese alloy powder includes mixing metal aluminum, metal copper and metal manganese according to the formula ratio, placing it in a vacuum induction melting furnace for melting at 700°C, and then Perform gas atomization powder making to obtain spherical powder, and pass through the powder collection device and screening device to obtain aluminum-copper-manganese alloy powder with a particle size of ≤200 mesh;

[0062] Based on the mass of the obtained Al-Cu-Mn alloy powder as 100%, the mass percentage of Al in the Al-Cu-Mn alloy powder is 92.9%, the mass percentage of Cu is 6.2%, and the mass percentage of Mn is 0.3% %, the content of impurity elements is 0.6%;

[0063] (2) the particle size obtained in step (1)≤200 mesh aluminum-copper-manganese alloy powder and the particle size≤2...

Embodiment 2

[0067] The difference between this embodiment and embodiment 1 is that the laser power in step (3) is 250W, the scan rate is 165mm / s, and other conditions are completely the same as those in embodiment 1.

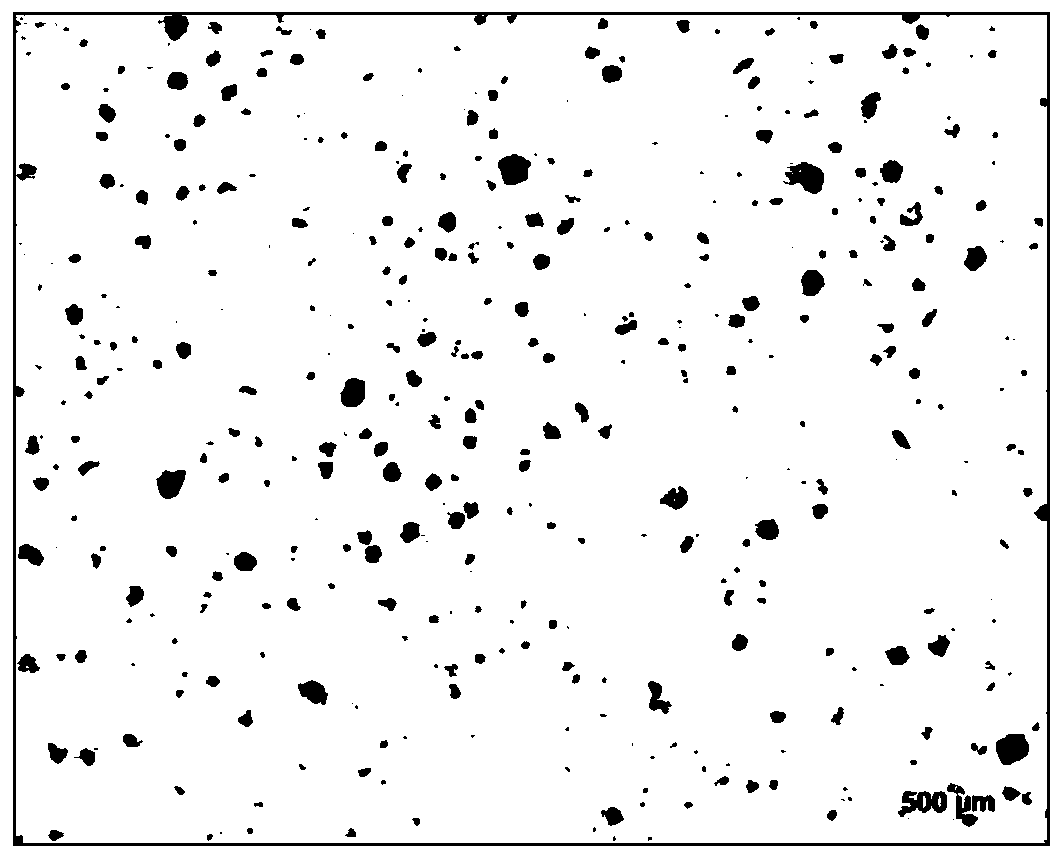

[0068] The morphology of the aluminum-copper-manganese porous composite material prepared in this example is as follows figure 2 As shown, it can be seen from the figure that the obtained aluminum-copper-manganese porous composite material has no thermal cracks and has circular closed cells. After testing, its porosity is 4.67%. According to the GB / T228-2010 standard, the aluminum-copper-manganese porous The mechanical performance test of the composite material shows that the microhardness is 72.22HV.

Embodiment 3

[0070] The difference between this embodiment and embodiment 1 is that the laser power in step (3) is 340W, the scan rate is 333mm / s, and other conditions are completely the same as those in embodiment 1.

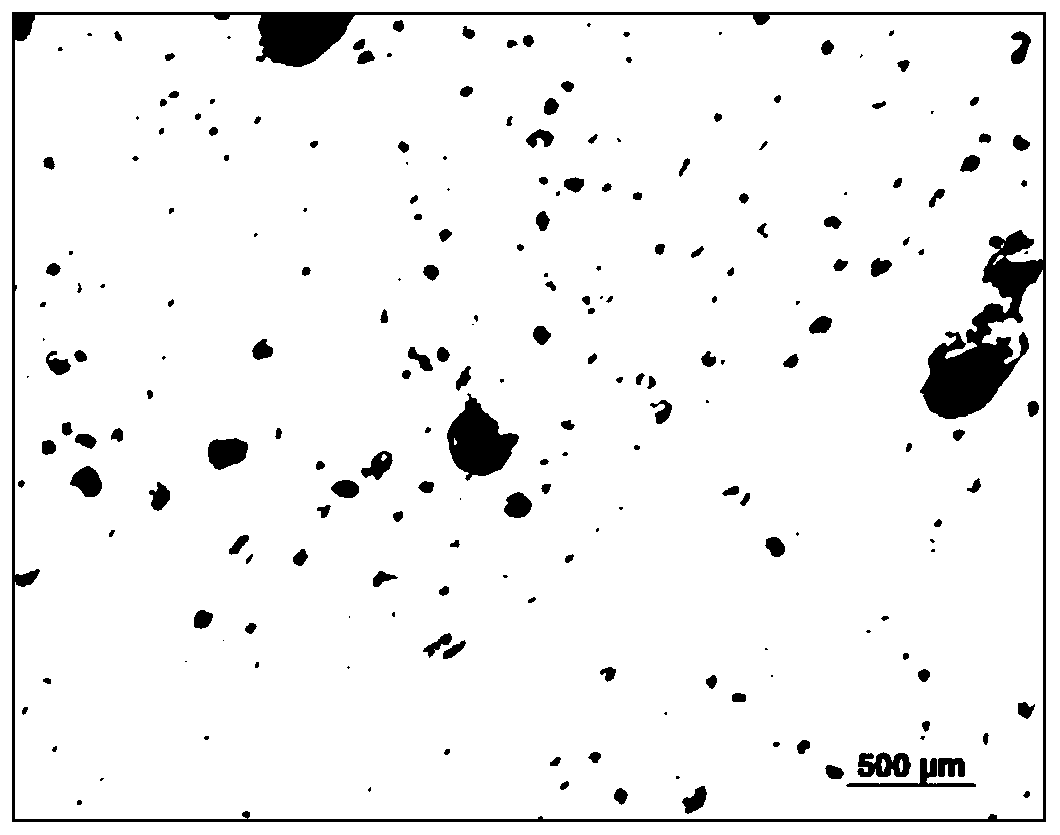

[0071] The morphology of the aluminum-copper-manganese porous composite material prepared in this example is as follows image 3 As shown, it can be seen from the figure that the obtained aluminum-copper-manganese porous composite material has no thermal cracks and has circular closed cells. After testing, its porosity is 4.32%. According to the GB / T228-2010 standard, the aluminum-copper-manganese porous The mechanical performance test of the composite material shows that the microhardness is 72.96HV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com