P-type local back surface field passivation double-sided solar cell and preparation process thereof

A technology of partial back surface field and double-sided solar cells, which is applied in the field of solar cells to achieve the effects of reducing floor space, saving silicon substrate materials, and reducing series resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

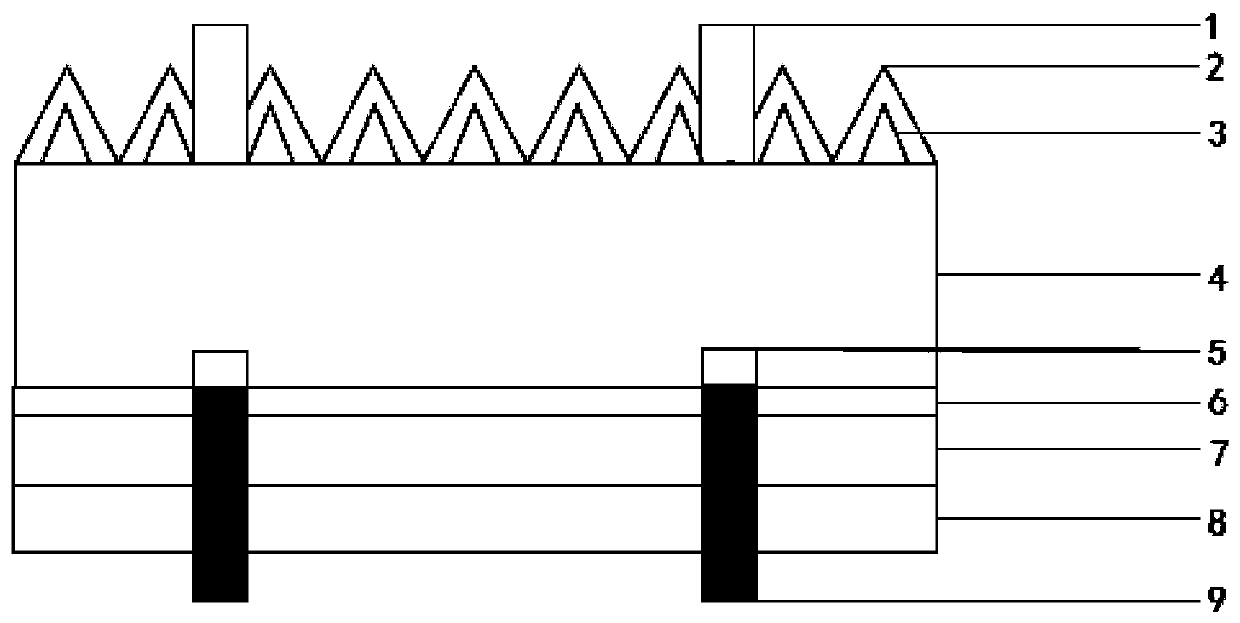

[0035] Such as figure 1 As shown, this embodiment provides a p-type partial back surface field passivation double-sided solar cell, including a p-type silicon substrate 4, and the bottom of the p-type silicon substrate 4 is provided with a silicon oxide passivation layer 6, An aluminum oxide passivation layer 7 and a silicon nitride antireflection layer 8 on the back side, a number of boron source doped layers 5 are embedded at the bottom of the p-type silicon substrate 4, and the bottom of the boron source doped layer 5 is connected with a passivation layer penetrating through silicon oxide at the same time. Layer 6, aluminum oxide passivation layer 7 and backside metal electrode layer 9 of silicon nitride antireflection layer 8.

[0036] A number of boron source doped layers 5 are embedded at the bottom of the p-type silicon substrate 4, thereby forming a back field high-low junction structure, which improves the open circuit voltage of the back cell of the double-sided sola...

Embodiment 2

[0044] Example 2

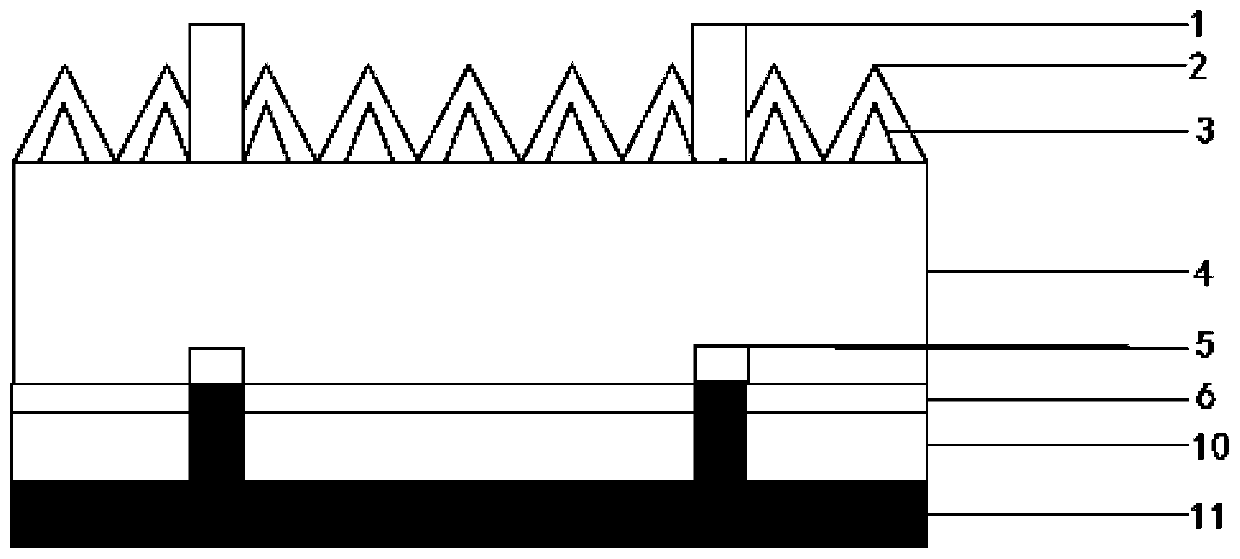

[0045] Such as figure 2 As shown, the present embodiment provides a p-type local back surface field passivation single-sided solar cell, comprising a p-type silicon substrate 4, and the bottom of the n-type silicon substrate is provided with a silicon oxide passivation layer 6 and this The bottom of the n-type silicon substrate is embedded with a number of boron source doped layers 5, and the bottom of the phosphorus source doped layer 3 is connected with a silicon oxide passivation layer 6 and an intrinsic amorphous silicon layer 10. Aluminum back field layer 11, and the aluminum back field layer 11 extends out to cover the lower surface of the intrinsic amorphous silicon layer 10, and the top of the n-type silicon substrate is provided with a phosphorus source doped layer 3 and a front silicon nitride in sequence from bottom to top The anti-reflection layer 2 and the phosphorus source doped layer 3 are provided with a plurality of front metal electrode l...

Embodiment 3

[0047] Such as figure 1 As shown, this embodiment provides a preparation process for a p-type local back surface field-passivated double-sided solar cell, including the following steps:

[0048] S1: select a p-type silicon substrate 4, clean the p-type silicon substrate 4, and perform surface polishing;

[0049] S2: performing low-pressure thermal diffusion on the upper surface of the p-type silicon substrate 4 to prepare the phosphorus source doped layer 3;

[0050] S3: performing ozone oxidation on the lower surface of the p-type silicon substrate 4 to grow a silicon oxide passivation layer 6;

[0051] S4: preparing a front silicon nitride anti-reflection layer 2 on the upper surface of the phosphorus source doped layer 3;

[0052] S5: preparing an aluminum oxide passivation layer 7 on the lower surface of the silicon oxide passivation layer 6;

[0053] S6: preparing a silicon nitride anti-reflection layer 8 on the lower surface of the aluminum oxide passivation layer 7; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com