3D porous zinc-loaded current collector, sodium or potassium-philic battery negative electrode and preparation and application thereof

A porous current collector and battery negative electrode technology, which is applied in battery electrodes, electrode carriers/current collectors, secondary batteries, etc., can solve the problem of poor wettability of metal sodium and metal potassium, uneven deposition of sodium/potassium, and poor cycle performance of batteries And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Clean nickel foam (Ni foam) (the thickness of the nickel foam current collector is 60 μm, the porosity is 60%, and the hole spacing is 120 μm) is placed in the following electroplating solution for zinc deposition.

[0083] The electroplating solution is an aqueous solution of zinc chloride, hydrochloric acid, and sodium lauryl sulfate, wherein 25 g / L of zinc chloride, 30 g / L of hydrochloric acid, 0.1 g / L of sodium lauryl sulfate, and the balance of water.

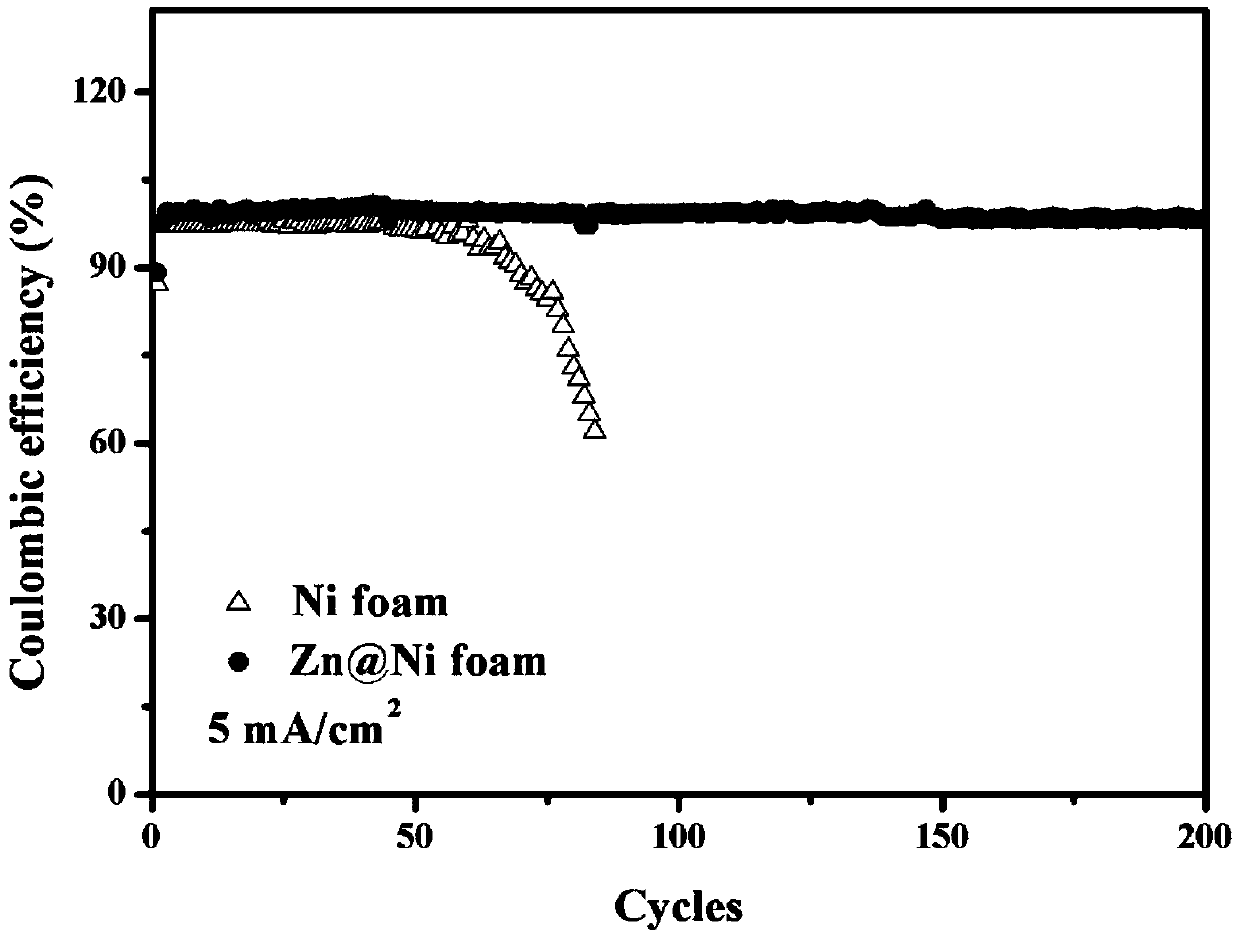

[0084] Electrodeposition with Ni foam as the working electrode, zinc plate as the counter electrode, at 8mA / cm 2 Deposit for 100 s to obtain zinc-coated nickel foam in the framework (marked as Zn@Ni foam) (the particle size of Zn is 100nm). Then the prepared Zn@Ni foam was used as the working electrode, the sodium sheet was used as the counter electrode, and 1M CF 3 SO 3 Na / DGDE (diethylene glycol dimethyl ether) was used as the electrolyte for re-discharge cycle tests.

[0085] The prepared Zn@Ni foam was used a...

Embodiment 2

[0088] Clean carbon nanotube paper (CNT paper) (the carbon nanotube paper current collector has a thickness of 30 μm, a porosity of 60%, and a pore spacing of 0.5 μm) is placed in the following electroplating solution for zinc deposition.

[0089] The electroplating solution is an aqueous solution of zinc acetate, acetic acid, and cetyltrimethylammonium bromide, wherein, zinc acetate 35g / L, acetic acid 50g / L, cetyltrimethylammonium bromide 0.2g / L, water margin.

[0090] Electrodeposition with CNT paper as the working electrode, zinc plate as the counter electrode, at 12mA / cm 2 Down deposition 60s, the carbon nanotube paper (marked as Zn@CNT paper) (the particle size of Zn is 20nm) ( Figure 4 ).

[0091] Then the prepared Zn@CNT paper was used as the working electrode, the sodium sheet was used as the counter electrode, and 1M CF 3 SO 3 Na / DGDE (diethylene glycol dimethyl ether) was used as the electrolyte for re-discharge cycle tests.

[0092] The prepared Zn@CNT paper w...

Embodiment 3

[0095] The Zn@CNT paper obtained in Example 2 is used as a working electrode, and then at a current density of 1mA / cm2, metal sodium of 5mAh / cm2 is deposited on the Zn@CNT paper working electrode to prepare a Na-Zn@CNT paper composite negative electrode material, Then form a sodium-sulfur battery with S-rich graphene cathode, at 1M CF 3 SO 3 In the electrolyte of Na / DGDE, the charge-discharge cycle test was carried out at 0.5C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com