Non-noble metal composite oxide honeycomb catalyst for low-carbon hydrocarbon catalytic combustion

A technology of composite oxides and honeycomb catalysts, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, heterogeneous catalyst chemical elements, etc., can solve phase formation difficulties, composite oxides and Weak carrier binding force, uneven distribution of coating active phase, etc., to achieve the effect of easy access to raw materials, good substitution of precious metal catalysts, and uniform and regular microscopic morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

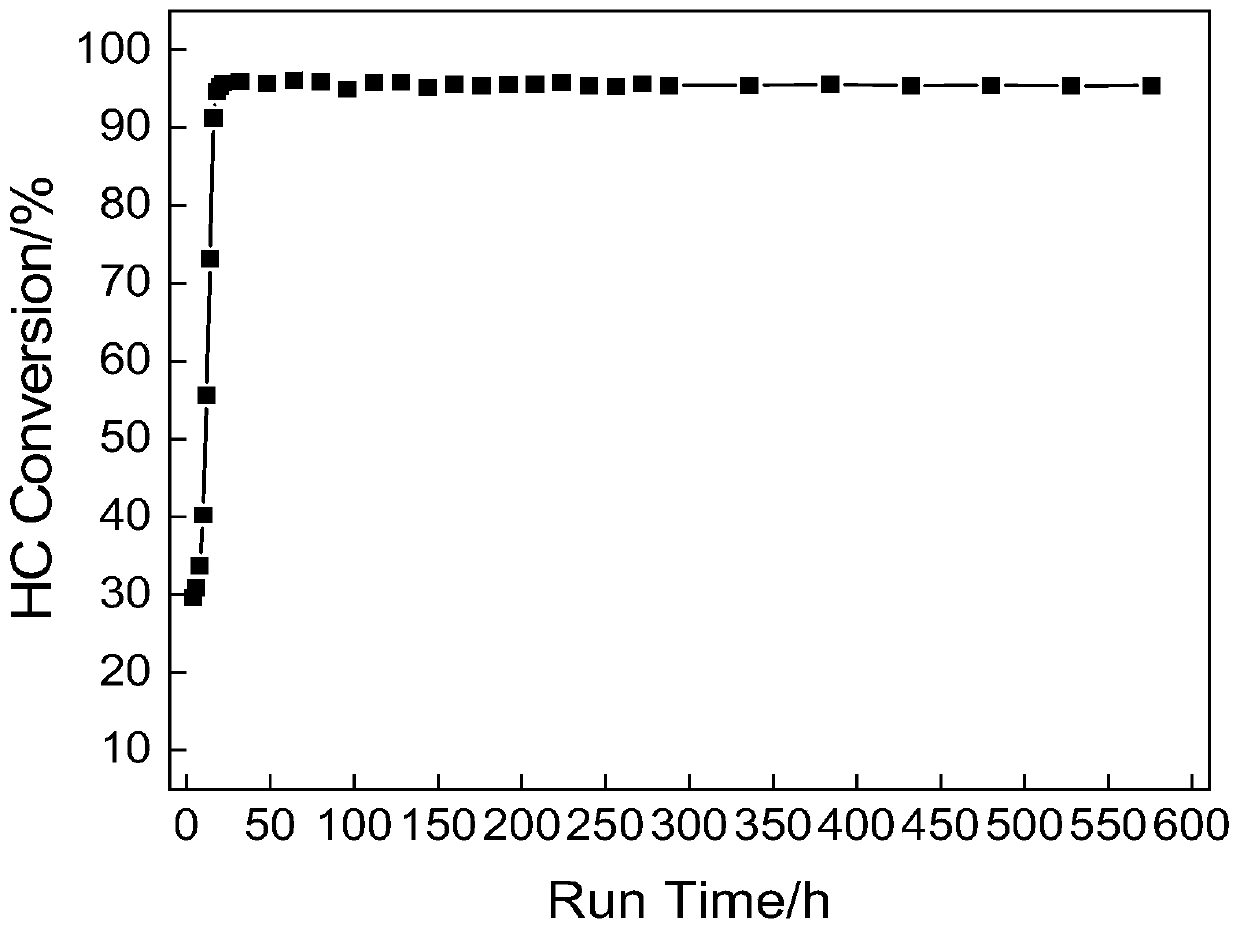

Examples

Embodiment 1

[0029] 1. Pretreatment of honeycomb ceramics

[0030] The cordierite honeycomb ceramics were placed in a muffle furnace and fired at 500°C for 4 hours to obtain pretreated cordierite honeycomb ceramics.

[0031] 2. Preparation of CuMn 2 CeO δ composite oxide

[0032] 24.16g (0.10mol) Cu(NO 3 ) 2 ·3H 2 O, 71.58g (0.20mol) 50% Mn (NO 3 ) 2 Solution, 43.41g (0.10mol) Ce(NO 3 ) 3 ·6H 2 O was dissolved in water and diluted to 800mL to make a solution with a total concentration of metal ions of 0.5mol / L, then 72g (1.20mol) of urea was added and stirred vigorously for 1h, transferred to a hydrothermal kettle, crystallized at 180°C for 12h, and then Filter the precipitate in the kettle, wash until neutral, dry at 100°C for 12h, and roast at 600°C for 6h to obtain CuMn 2 CeO δ composite oxides.

[0033] 3. Preparation of coating solution

[0034] 24g CuMn 2 CeO δComposite oxide, 6g pseudo-boehmite, 2g PEG-4000, 53g water, 5g ethanol are blended, highly dispersed by a pl...

Embodiment 2

[0038] 1. Pretreatment of honeycomb ceramics

[0039] The cordierite honeycomb ceramics were placed in a muffle furnace and fired at 500°C for 4 hours to obtain pretreated cordierite honeycomb ceramics.

[0040] 2. Preparation of CuMn 2 Ce 2 o δ composite oxide

[0041] 19.33g (0.08mol) Cu(NO 3 ) 2 ·3H 2 O, 57.26g (0.16mol) 50% Mn (NO 3 ) 2 solution, 69.47g (0.16mol) Ce(NO 3 ) 3 ·6H 2 O was dissolved in water and diluted to 800mL to prepare a solution with a total concentration of metal ions of 0.5mol / L, then added 72.07g (1.20mol) of urea and stirred vigorously for 1h, transferred to a hydrothermal kettle, and crystallized at 180°C for 12h. Thereafter, the precipitate in the kettle was filtered, washed until neutral, dried at 100°C for 12 hours, and calcined at 600°C for 6 hours to obtain CuMn 2 Ce 2 o δ composite oxides.

[0042] 3. Preparation of coating solution

[0043] 24g CuMn 2 Ce 2 o δ Composite oxide, 6g pseudo-boehmite, 2g PEG-4000, 53g water, 5g ...

Embodiment 3

[0047] 1. Pretreatment of honeycomb ceramics

[0048] The cordierite honeycomb ceramics were placed in a muffle furnace and fired at 500°C for 4 hours to obtain pretreated cordierite honeycomb ceramics.

[0049] 2. Preparation of CuMn 2 Ce 3 o δ composite oxide

[0050] 16.91g (0.07mol) Cu(NO 3 ) 2 ·3H 2 O, 50.11g (0.14mol) 50% Mn (NO 3 ) 2 Solution, 91.19g (0.21mol) Ce(NO 3 ) 3 ·6H 2 Dissolve O in water and dilute to 840mL to make a solution with a total metal ion concentration of 0.5mol / L, then add 75.68g (1.26mol) urea and stir vigorously for 1h, transfer to a hydrothermal kettle, and crystallize at 180°C for 12h, Thereafter, the precipitate in the kettle was filtered, washed until neutral, dried at 100°C for 12 hours, and calcined at 600°C for 6 hours to obtain CuMn 2 Ce 3 o δ composite oxides.

[0051] 3. Preparation of coating solution

[0052] 24g CuMn 2 Ce 3 o δ Composite oxide, 6g pseudo-boehmite, 2g PEG-4000, 5-3g water, 5g ethanol are blended, hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com