Self-compensating free radical ion salt, preparation method thereof, and photoelectric device

A technology of photoelectric devices and free radicals, which is applied in the direction of electric solid devices, sulfonate preparation, photovoltaic power generation, etc., can solve the problems of poor interface modification ability, low stability, limited free radical concentration, etc., and achieve the overall efficiency of the device , increase the concentration, and promote the effect of charge transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

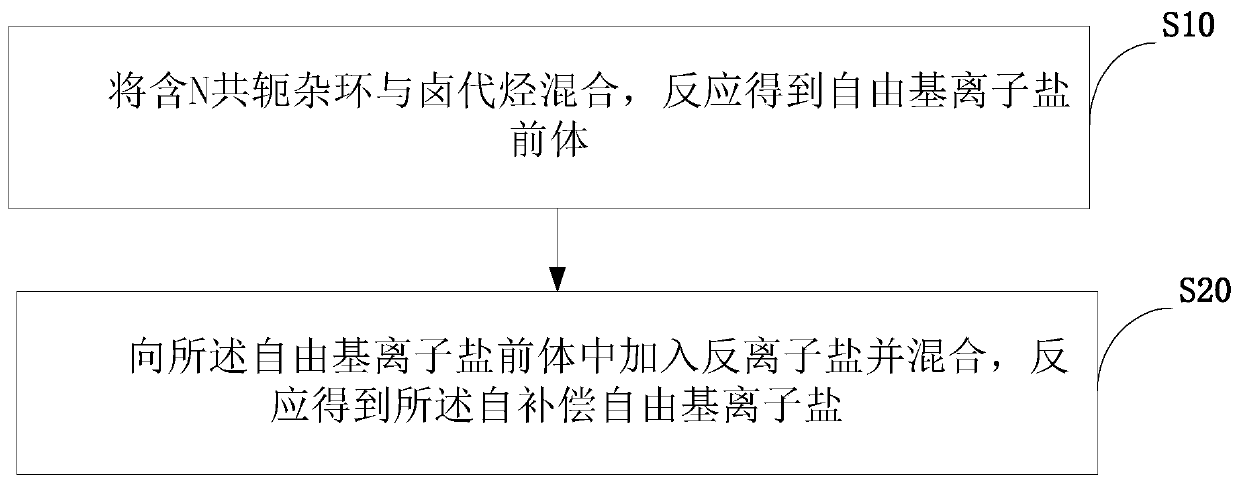

[0038] see figure 1 , figure 1 A flow chart of a preferred embodiment of a self-compensating free radical ion salt preparation method provided by the present invention, as shown in the figure, includes the following steps:

[0039] S10, mixing an N-containing conjugated heterocyclic ring with a halogenated hydrocarbon, and reacting to obtain a free radical ion salt precursor;

[0040] S20 / Adding a counter ion salt to the precursor of the free radical ion salt and mixing, reacting to obtain the self-compensating free radical ion salt.

[0041] Through the method provided in this example, the self-compensating free radical ion salt can be prepared simply and quickly. The prepared self-compensating free radical ion salt contains free radicals with high concentration and high stability. The principle of achieving the above effects is as follows:

[0042] In this example, by mixing N-heteroconjugated heterocyclic rings with quaternary ammonium halogenated hydrocarbons, while rea...

Embodiment 1

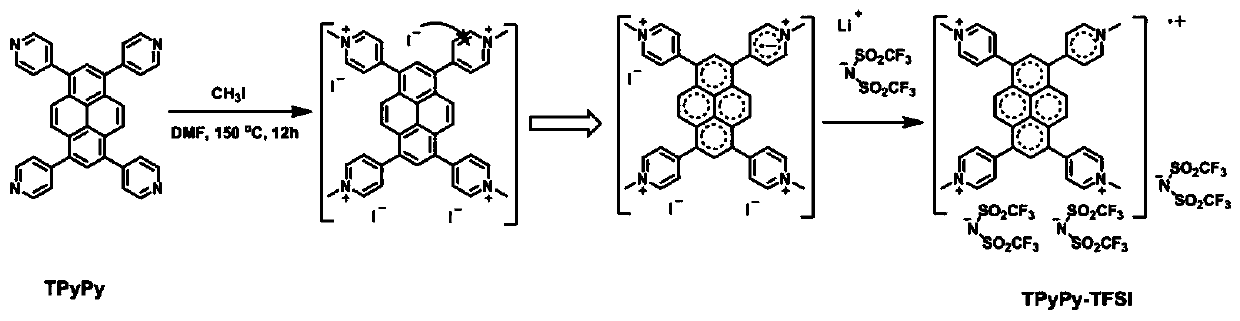

[0071] The preparation of embodiment 1TPyPy-TFSI radical ion salt

[0072] The specific synthetic route is as figure 2 shown. First weigh 510mg of TPyPy (1mmol) into a 25mL Chirank tube, add 5mL of ultra-dry DMF and 1.2g of methyl iodide (8mmol, excess) in sequence, then freeze the system into a solid with liquid nitrogen, vacuumize the system with an oil pump, and then fill it with Inject dry argon, and repeat the pumping three times. The system was sealed, then placed in a reactor at 150°C, and stirred in the dark for 12 hours, then cooled to room temperature and then transferred to a glove box. The suspension was added dropwise to the dry diethyl ether solution, stirred to disperse, precipitated, and then filtered to obtain a brown-yellow solid powder. Wash the solid phase successively with petroleum ether and tetrahydrofuran, and drain it for later use. Then disperse the brown yellow solid powder in an appropriate amount of ultra-dry methanol solution, add excess lith...

example 2

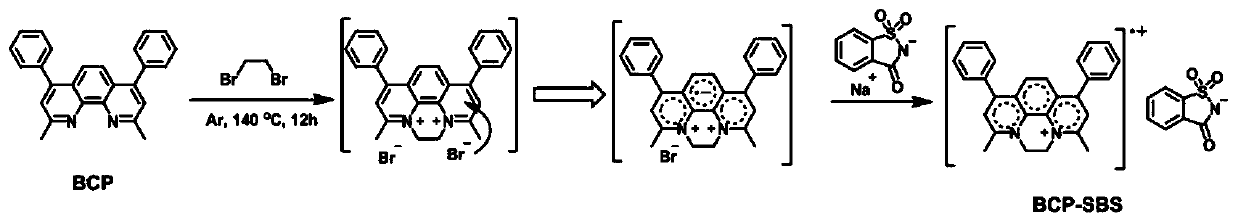

[0075] Example 2: Preparation of BCP-SBS radical ion salt

[0076] The specific synthetic route is as image 3 shown. First, weigh 720mg of BCP (2mm) into a 25mL ultra-dry Chirank tube, then add 10mL of re-distilled 1,2-dibromoethane, use liquid nitrogen to reduce the suspension to below the freezing point, and use an oil pump to Vacuumize, refill with dry argon, repeat this operation three times, then seal the system away from light and place it in a reactor at 140°C, stir at this temperature for 12 hours, cool to room temperature, and transfer to a glove box for processing. Add the brown suspension dropwise to the stirred ultra-dry diethyl ether solution, then filter to obtain a tan solid powder, wash with petroleum ether and tetrahydrofuran ultra-dry solution successively, drain and transfer to the outside of the glove box for later use. Dissolve the solid in an appropriate amount of methanol solution, add excess sodium saccharin, stir at room temperature for 3 to 5 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com