Silver-containing nanometer composite antibacterial coating and preparation method thereof

A composite antibacterial and silver nanotechnology, used in coatings, paints containing biocides, antifouling/underwater coatings, etc. Effect, low cost, high mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

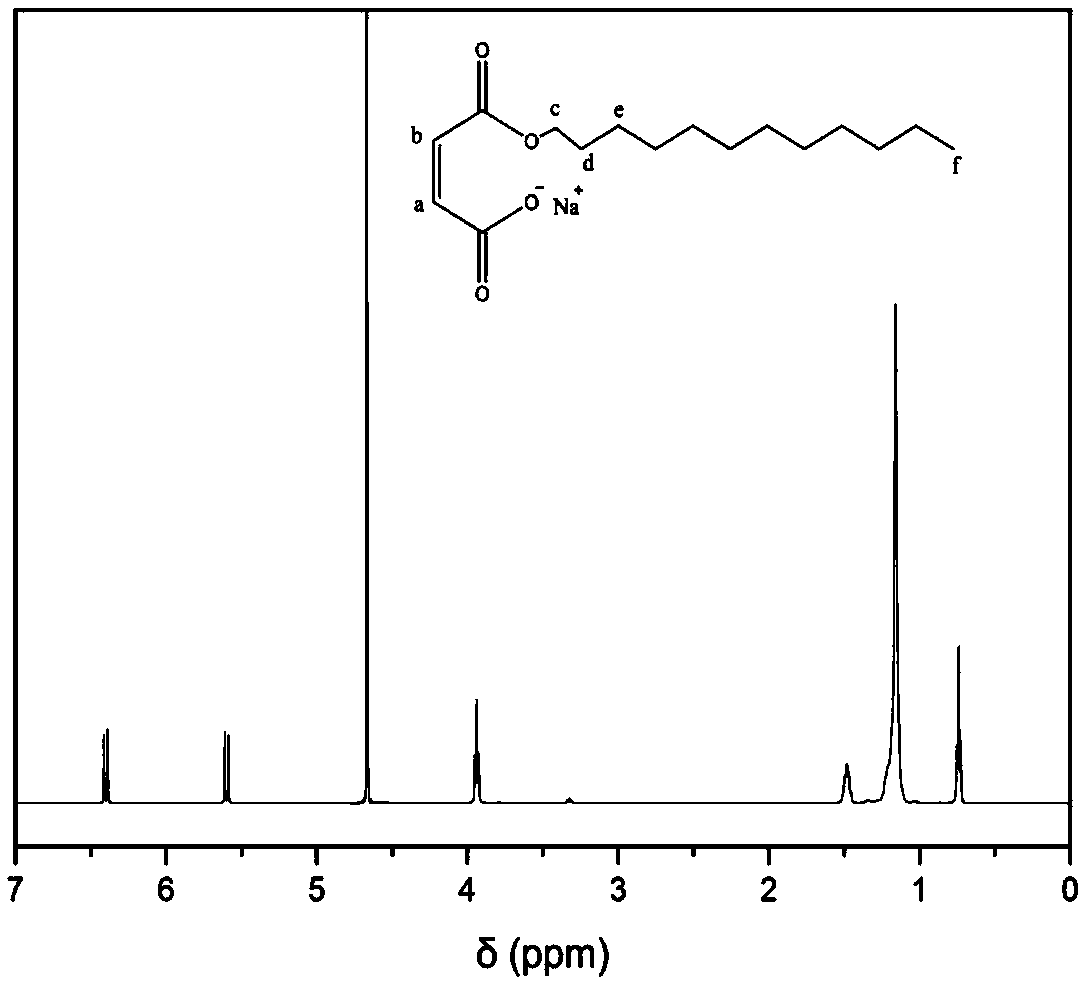

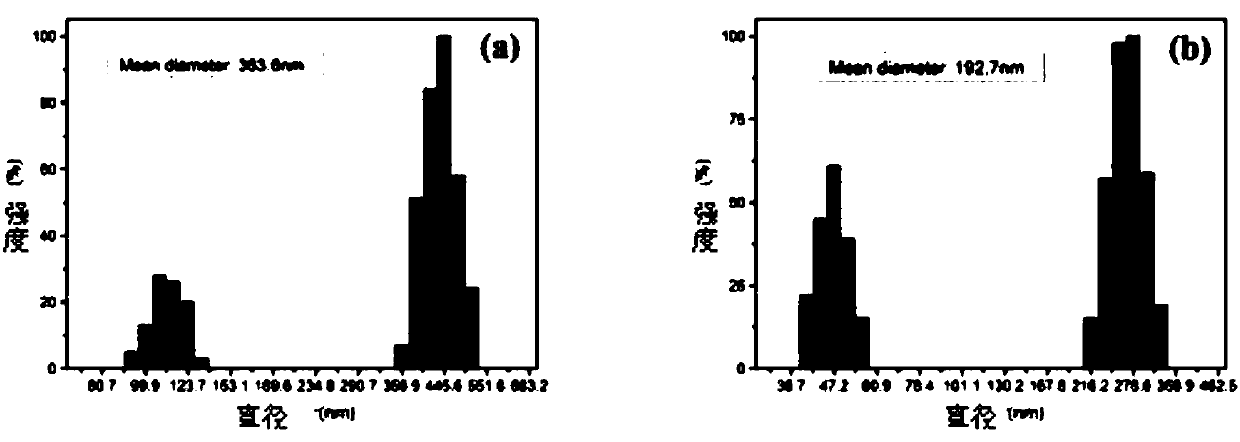

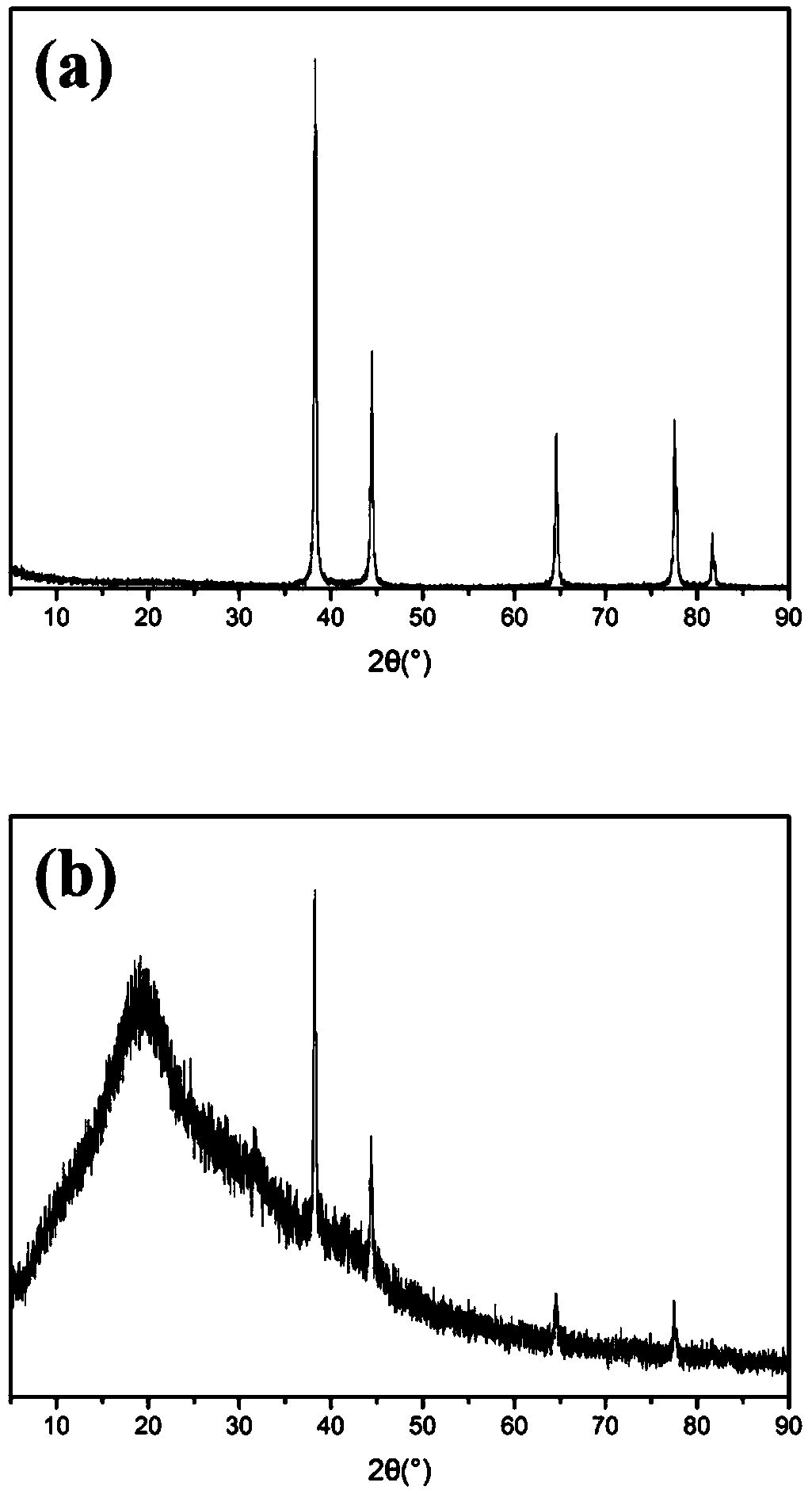

[0040] Preparation of P(MMA-co-BA-co-MAMS) / Ag nanocomposite antibacterial coating:

[0041] (1) Weigh 0.5g MAMS, 0.057g initiator KPS, dissolve them in 50mL deionized water, then weigh 5g monomer butyl acrylate and 5g methyl methacrylate, add them into a 100mL four-necked flask, and Stir at a rotating speed for pre-emulsification for 2 hours. After the end, add the pre-emulsion into the constant pressure dropping funnel for use;

[0042] (2) Then disperse 0.5g of Ag nanoparticles and 0.5g of MAMS in 50mL of deionized water, and use JY92-II N-type ultrasonic cell pulverizer to ultrasonically disperse. The set parameters are: power 600W, working time 3s, intermittent time 2s, Sonicate for 30 minutes in an ice bath environment, add the ultrasonic dispersion into a 250mL four-necked flask; then weigh 5g of butyl acrylate and 5g of methyl methacrylate, add them to a 250mL four-necked flask, pre-emulsify in a water bath at room temperature for 0.5h, set The stirring speed is 700rpm...

Embodiment 2

[0046] (1) Weigh 0.5g MAMS, 0.057g initiator KPS, dissolve them in 50mL deionized water, then weigh 5g monomer butyl acrylate and 5g methyl methacrylate, add them into a 100mL four-necked flask, and Stir at a rotating speed for pre-emulsification for 2 hours. After the end, add the pre-emulsion into the constant pressure dropping funnel for use;

[0047] (2) Then disperse 0.25g of Ag nanoparticles and 0.5g of MAMS in 50mL of deionized water, and use JY92-II N-type ultrasonic cell pulverizer to ultrasonically disperse. The set parameters are: power 600W, working time 3s, intermittent time 2s, Sonicate for 30 minutes in an ice bath environment, add the ultrasonic dispersion into a 250mL four-necked flask; then weigh 5g of butyl acrylate and 5g of methyl methacrylate, add them to a 250mL four-necked flask, pre-emulsify in a water bath at room temperature for 0.5h, set The stirring speed is 700rpm, and after 0.5h, the temperature starts to rise; when the temperature reaches 65°C, ...

Embodiment 3

[0051] (1) Weigh 0.5g MAMS, 0.057g initiator KPS, dissolve them in 50mL deionized water, then weigh 5g monomer butyl acrylate and 5g methyl methacrylate, add them into a 100mL four-necked flask, and Stir at a rotating speed for pre-emulsification for 2 hours. After the end, add the pre-emulsion into the constant pressure dropping funnel for use;

[0052] (2) Disperse 1.0g of Ag nanoparticles and 0.5g of MAMS in 50mL of deionized water, and use JY92-II N-type ultrasonic cell pulverizer to ultrasonically disperse. The set parameters are: power 600W, working time 3s, intermittent time 2s, Sonicate for 30 minutes in an ice bath environment, add the ultrasonic dispersion into a 250mL four-necked flask; then weigh 5g of butyl acrylate and 5g of methyl methacrylate, add them to a 250mL four-necked flask, pre-emulsify in a water bath at room temperature for 0.5h, set The stirring speed is 700rpm, and after 0.5h, the temperature starts to rise; when the temperature reaches 66°C, weigh ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com