Aronia melanocarpa extract and preparation method thereof

A technology of Aronia arborica and its extract, which is applied in the field of manufacturing Aronia arborica extract and its preparation, can solve the problems of incomplete separation of sugar and polyphenols, and achieve the goal of preventing and treating atherosclerosis Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1: Preparation method of high-sugar extract of Aronia adenocarpus:

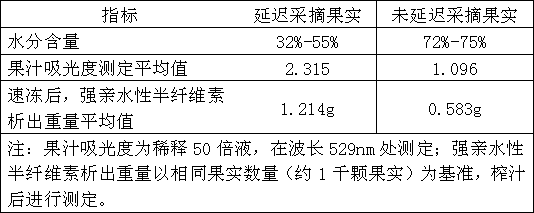

[0048] 1. Delayed fruit picking:

[0049] Picking of Sorbus adenocarpus fruit is delayed for 30-60 days, and the water evaporation of the fruit is 20-40% of the weight of the original fresh fruit, and 30-35% is the best.

[0050] 2. Pick, wash and drain:

[0051] The picked fruits are artificially screened to remove impurities such as rotten, moldy, spoiled, and off-flavored fruits, leaves, stones, and fruit stems. Immerse the selected fruit in 3-4 times of clean water, add 0.1-0.3% of the weight of edible detergent to soak for 10 minutes, stir gently, keep it for more than 10 minutes, let go of the dirty water, change to clean water and rinse 2-3 times, remove Drain and control dry.

[0052] 3. Quick freezing:

[0053] Quick-freeze the dried fruit. Within 2 hours, the temperature of the fruit center is reduced to -6°C to -18°C, and -10°C to -12°C is the best.

[0054] 4. Crushing, beating,...

Embodiment 2

[0062] Embodiment 2: the preparation method of low-sugar extract of Aronia adenocarpa:

[0063] 1. Delayed fruit picking:

[0064] Same as Example 1.

[0065] 2. Select, clean and drain:

[0066] Same as Example 1.

[0067] 3. Quick freezing:

[0068] Same as Example 1.

[0069] 4. Crushing, beating and enzymatic hydrolysis and separation of skin dregs:

[0070] Same as Example 1.

[0071] 5. Hot leaching of skin dregs:

[0072] Same as Example 1.

[0073] 6. Yeast inoculation and fermentation:

[0074] Add 0.01-0.02% Saccharomyces cerevisiae active dry yeast to the fruit juice after separating the skin dregs, at an ambient temperature of 16-25°C, a central temperature of the fermentation liquid of 25-30°C, an air flow of 30-50v / v h, and a pH of 3.5-4.5 conditions for rapid aerobic fermentation. When the sugar content of the fruit juice is reduced below 1%, the fermentation is terminated.

[0075] 7. Low temperature treatment, filtration and acid reduction:

[0076...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com