Portable NO production machine

A nitric oxide and manufacturing machine technology, which is applied in the field of medical devices, can solve problems such as potential safety hazards, and achieve the effects of low maintenance costs, safe and reliable raw materials, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

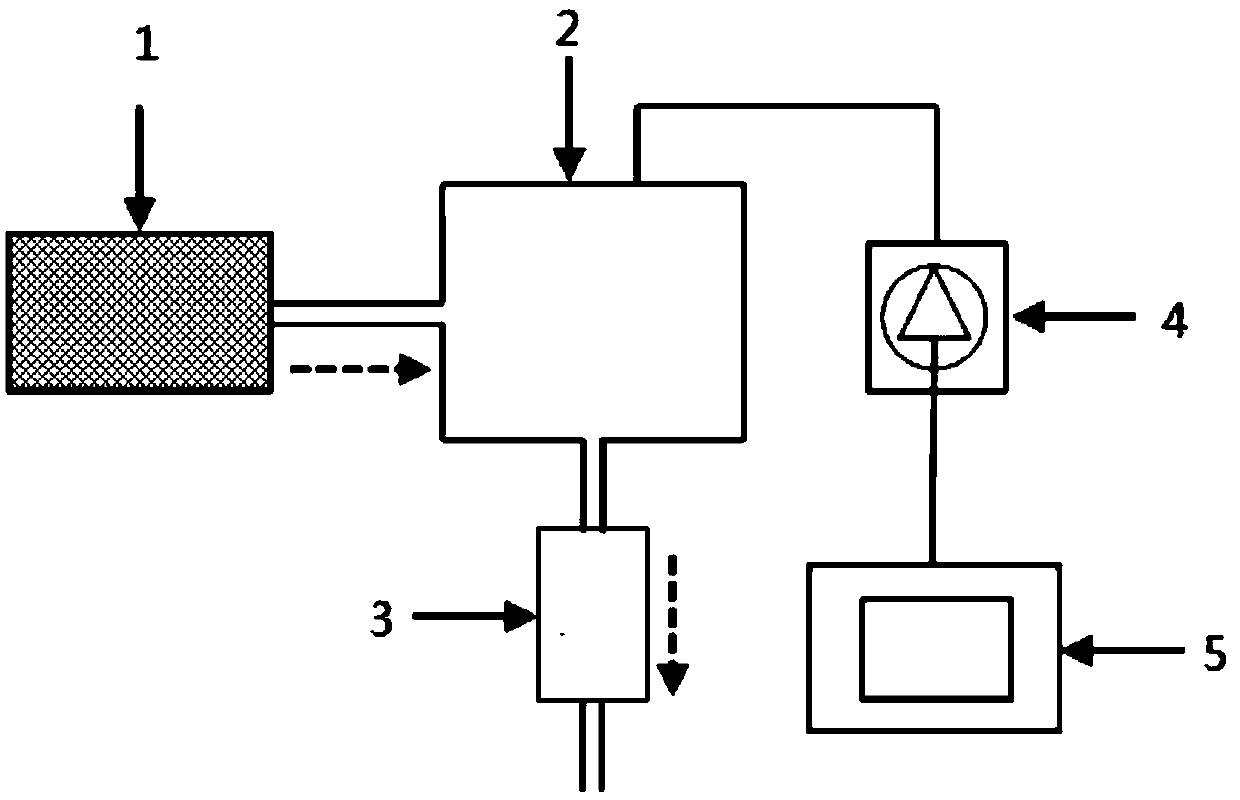

Method used

Image

Examples

Embodiment 1

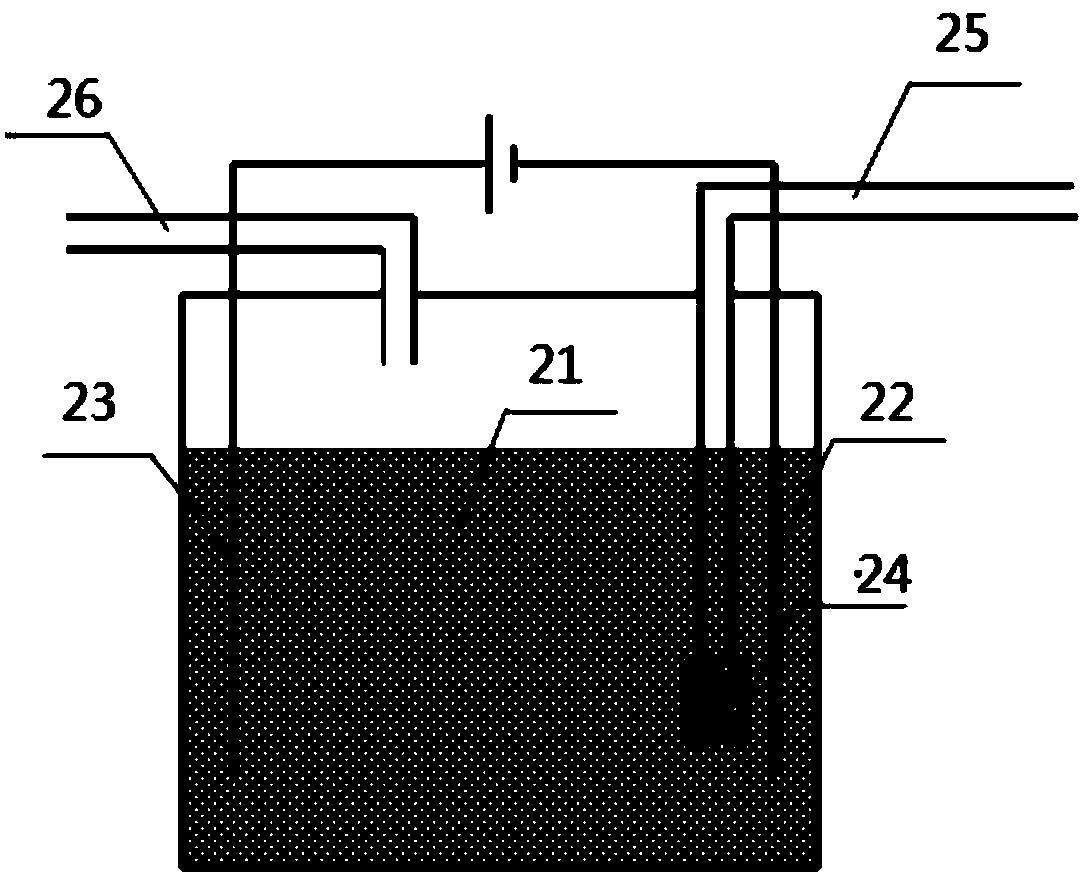

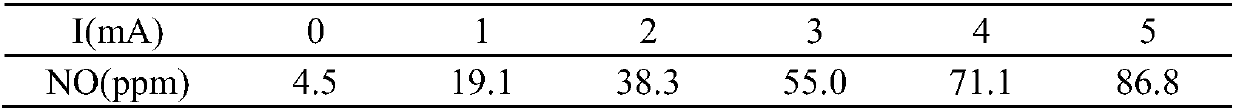

[0031]Specifically, the solution used for electrochemically generating nitric oxide is a buffer solution containing 1M sodium nitrite and 7mM copper catalyst. Electrode material: soft stainless steel mesh; working electrode×reference electrode: 9cm×3cm; the nitrogen outlet is juxtaposed with the negative electrode of the electrode, and the nitric oxide adsorbed on the surface of the electrode and dissolved in the solution is separated and taken away from the reaction vessel, and is oxidized by nitrogen Analyzer for detection.

[0032] The flow rate of nitrogen gas was controlled to be 0.7 L / min, and no current was applied. At this time, the detection concentration of nitric oxide was 4.5 ppm (Table 1).

[0033] Change the magnitude of the applied current (1-5mA), at this time, the detection concentration of nitric oxide increases linearly, and the growth rate is about 16.8ppm / mA. Under the action of 5mA current, the concentration of nitric oxide is as high as 86.8ppm.

[0034...

Embodiment 2

[0037] Specifically, the electrolyte is a buffer solution containing 1M sodium nitrite and 7mM copper catalyst. Electrode material: gold-plated soft stainless steel mesh; working electrode × reference electrode: 9cm × 3cm.

[0038] Control the flow rate of nitrogen to 0.7L / min, choose gold-plated soft stainless steel mesh as the working electrode, change the magnitude of the action current (1~5mA), the concentration of nitric oxide increases linearly, and the growth rate is about 17.5ppm / mA. The nitrogen concentration was as high as 93.3 ppm (Table 2). Compared with the soft stainless steel mesh, the concentration of nitric oxide has increased to a certain extent.

[0039] Table 2. Changes of nitric oxide (NO) concentration with current

[0040]

Embodiment 3

[0042] Specifically, the electrolyte is a buffer solution containing 1M sodium nitrite and 7mM copper catalyst. Electrode material: soft stainless steel mesh; working electrode×reference electrode: 9cm×3cm; the total flow rate of the control gas is 0.7L / min, the solution is purged with nitrogen, and the mixing ratio of nitrogen and air is changed, and the gas outlet is juxtaposed with the negative electrode of the electrode , the nitric oxide adsorbed on the surface of the electrode and dissolved in the solution is separated and taken away from the reaction vessel, and detected by a nitric oxide gas analyzer.

[0043] Control the total gas flow rate to 0.7L / min, and fix the mixing ratio of nitrogen and air (R(N 2 / Air) can be 2, 1, 0.5), at this time, the detected concentration of NO increases linearly with the increase of current.

[0044] Change the mixing ratio of nitrogen and air (R(N 2 / Air) take 2, 1, 0.5), at this time, the detection concentration of NO increases with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com