Polymer cement waterproof paint suitable for low-temperature environment and preparation method thereof

A waterproof coating and low-temperature environment technology, applied in the field of polymer cement waterproof coating, can solve the problems of attenuation of elongation at break, no self-repair ability, easy cracking of waterproof layer, etc., and achieve the effect of excellent toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

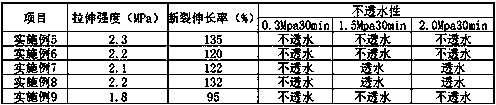

Examples

Embodiment 1

[0030] A polymer cement waterproof coating suitable for low temperature environment, including liquid material and powder material.

[0031] The liquid material includes the following raw materials in parts by weight: 25 parts of composite emulsion, 25 parts of plasticizer, 1 part of dispersant, 0.5 part of preservative and 10 parts of water;

[0032] The cement is Portland cement. The plasticizer is dioctyl phthalate. The dispersant is polyacrylic acid sodium salt dispersant. The preservative is Nord C15 bactericidal preservative. The water reducer is a polycarboxylate type water reducer.

[0033] The powder includes the following raw materials in parts by weight: 35 parts of cement, 20 parts of filler, and 1 part of water reducer;

[0034] The filler includes 8 parts of sodium carbonate, 10 parts of vermiculite powder, 10 parts of cordierite micropowder, 8 parts of water glass and 10 parts of nano white carbon black.

[0035] The composite emulsion includes the followin...

Embodiment 2

[0037] A polymer cement waterproof coating suitable for low temperature environment, including liquid material and powder material.

[0038] The liquid material includes the following raw materials in parts by weight: 15 parts of composite emulsion, 20 parts of plasticizer, 1 part of dispersant, 0.1 part of preservative and 15 parts of water;

[0039] The cement is aluminate cement. The plasticizer is dioctyl adipate. The dispersant is sodium dodecylbenzenesulfonate. The preservative is Dovihill-75. The water reducer is a melamine water reducer.

[0040] The powder includes the following raw materials in parts by weight: 30 parts of cement, 25 parts of filler, and 0.5 part of water reducer;

[0041] The filler includes 5 parts of sodium carbonate, 12 parts of vermiculite powder, 8 parts of cordierite micropowder, 10 parts of water glass and 5 parts of nano white carbon black.

[0042] The composite emulsion includes the following raw materials in parts by weight: 10 parts...

Embodiment 3

[0044] A polymer cement waterproof coating suitable for low temperature environment, including liquid material and powder material.

[0045] The liquid material includes the following raw materials in parts by weight: 30 parts of composite emulsion, 35 parts of plasticizer, 0.5 part of dispersant, 0.5 part of preservative and 8 parts of water;

[0046] The cement is aluminate cement. The plasticizer is epoxy octyl stearate. The dispersant is sodium hexametaphosphate. The preservative is Nord C15 bactericidal preservative. The water reducer is a melamine water reducer.

[0047]The powder includes the following raw materials in parts by weight: 40 parts of cement, 15 parts of filler, and 2 parts of water reducing agent;

[0048] The filler includes 10 parts of sodium carbonate, 8 parts of vermiculite powder, 15 parts of cordierite micropowder, 5 parts of water glass and 15 parts of nano white carbon black.

[0049] The composite emulsion includes the following raw materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com