A kind of epoxy resin/montmorillonite nanocomposite coating for metal surface

An epoxy resin and nanocomposite technology, applied in epoxy resin coatings, anti-corrosion coatings, coatings and other directions, can solve the problems of accelerated metal corrosion, slow curing and drying speed, long time, etc., to increase flexibility, huge reserves, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

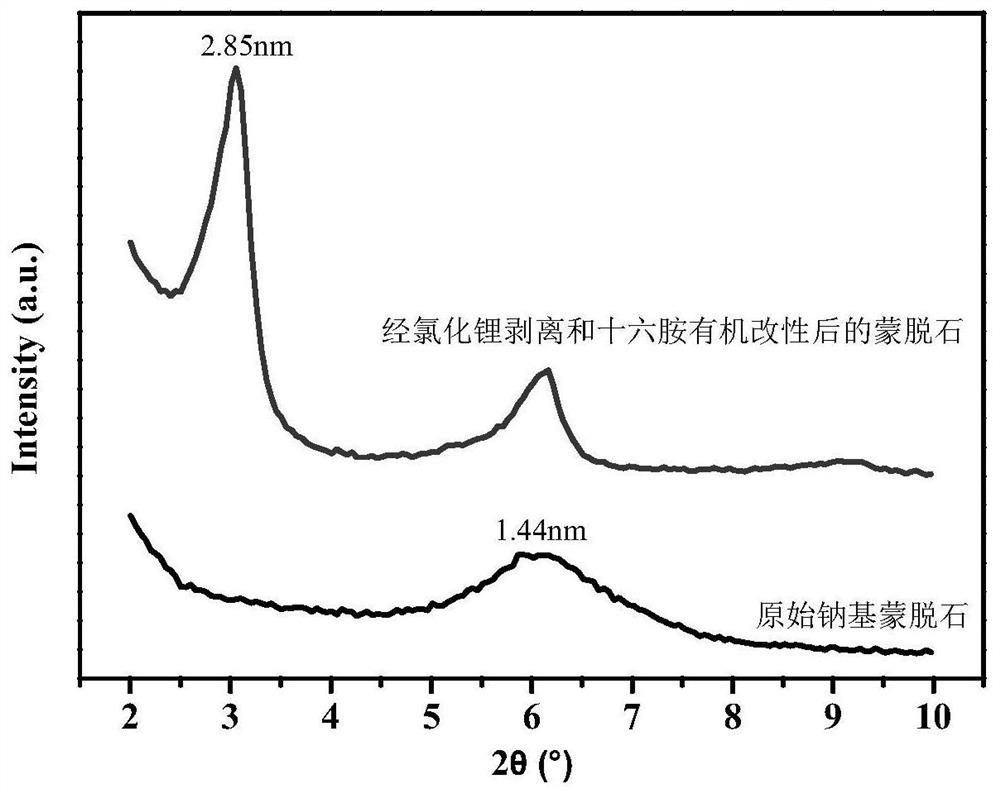

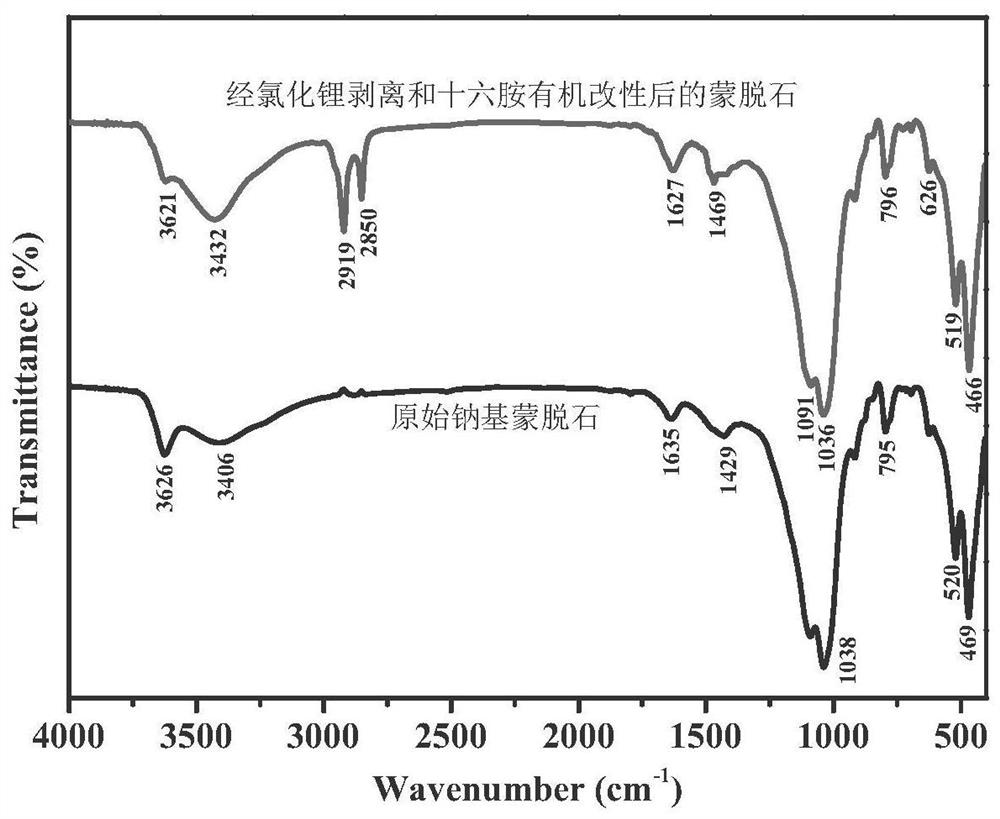

[0044] Preparation of hexadecylamine modified montmorillonite:

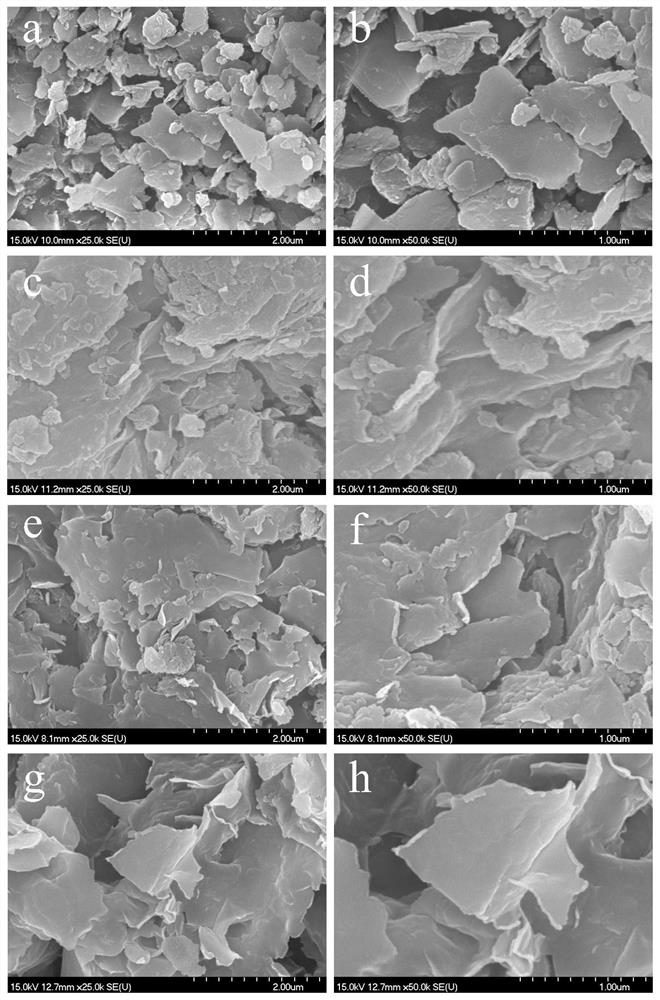

[0045] Dissolve the original sodium-based montmorillonite and deionized water in a 2000mL beaker at a ratio of 1:20, ultrasonic (200W, 100%), accompanied by mechanical stirring (20Kr / min) for 12h, and stand still for 72h, after the stratification is obvious Get the middle colloidal part and centrifuge (8000r / min, 6min), and the precipitation in the centrifuge tube is dried for subsequent use with a beaker, obtain the montmorillonite after purification ( image 3 e, 3f, with a thickness of about 0.12 μm). Take 8mol·L -1 Lithium chloride solution is used as stripping agent, 2g of purified montmorillonite and 70mL of lithium chloride solution are evenly mixed in a 100mL hydrothermal reaction kettle, hydrothermal reaction is carried out at 140°C for 24 hours, and the sample is centrifuged and washed until the separation liquid does not contain Cl - (Add AgNO 3 no precipitation), dried and ground to obtain the strip...

Embodiment 1

[0049] Preparation of epoxy resin / montmorillonite nanocomposite film: Add 100 parts of epoxy resin E51, 3 parts of organically modified montmorillonite, and 15 parts of reactive diluent 669 into a 250 mL three-necked flask, stir well, and heat up to 80 ° C. Insulate and stir for 2 hours, then ultrasonically disperse at 80°C for 10 minutes, and then vacuum defoam for 10 minutes; after cooling to close to room temperature, add 50 parts of curing agent polyamide 650 and 3 parts of accelerator DMP-30 into the mixture, stir well and then coat One layer was placed on the surface of the aluminum sheet and cured at room temperature for 48 hours to prepare the epoxy resin / montmorillonite nanocomposite material.

[0050] The CHI660 electrochemical workstation of Shanghai Chenhua Company was used to test the salt resistance (1.0mol / L NaCl solution) and acid resistance (0.5mol / L H 2 SO 4 Solution) corrosion electrochemical test, the results are as follows Image 6 , 7 , 8 and 9, it can...

Embodiment 2

[0052] Preparation of epoxy resin / montmorillonite nanocomposite film: Add 100 parts of epoxy resin E51, 3 parts of organically modified montmorillonite, and 15 parts of reactive diluent 669 into a 250 mL three-necked flask, stir well, and heat up to 80 ° C. Insulate and stir for 2 hours, then ultrasonically disperse at 80°C for 10 minutes, and then vacuum defoam for 10 minutes; after cooling to close to room temperature, add 50 parts of curing agent polyamide 650 and 3 parts of accelerator DMP-30 into the mixture, stir well and then coat Two layers were placed on the surface of the aluminum sheet and cured at room temperature for 48 hours to prepare the epoxy resin / montmorillonite nanocomposite material.

[0053] The CHI660 electrochemical workstation of Shanghai Chenhua Company was used to test the salt resistance (1.0mol / L NaCl solution) and acid resistance (0.5mol / L H 2 SO 4 Solution) corrosion electrochemical test, the results are as follows Image 6 , 7 , 8 and 9, it c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion potential | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com