High-performance two-component epoxy primer for rail transit and preparation process thereof

A technology for rail transit and epoxy primer, applied in the field of coatings, can solve problems such as poor salt spray resistance, and achieve the effect of suitable crosslinking density, improved compatibility and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

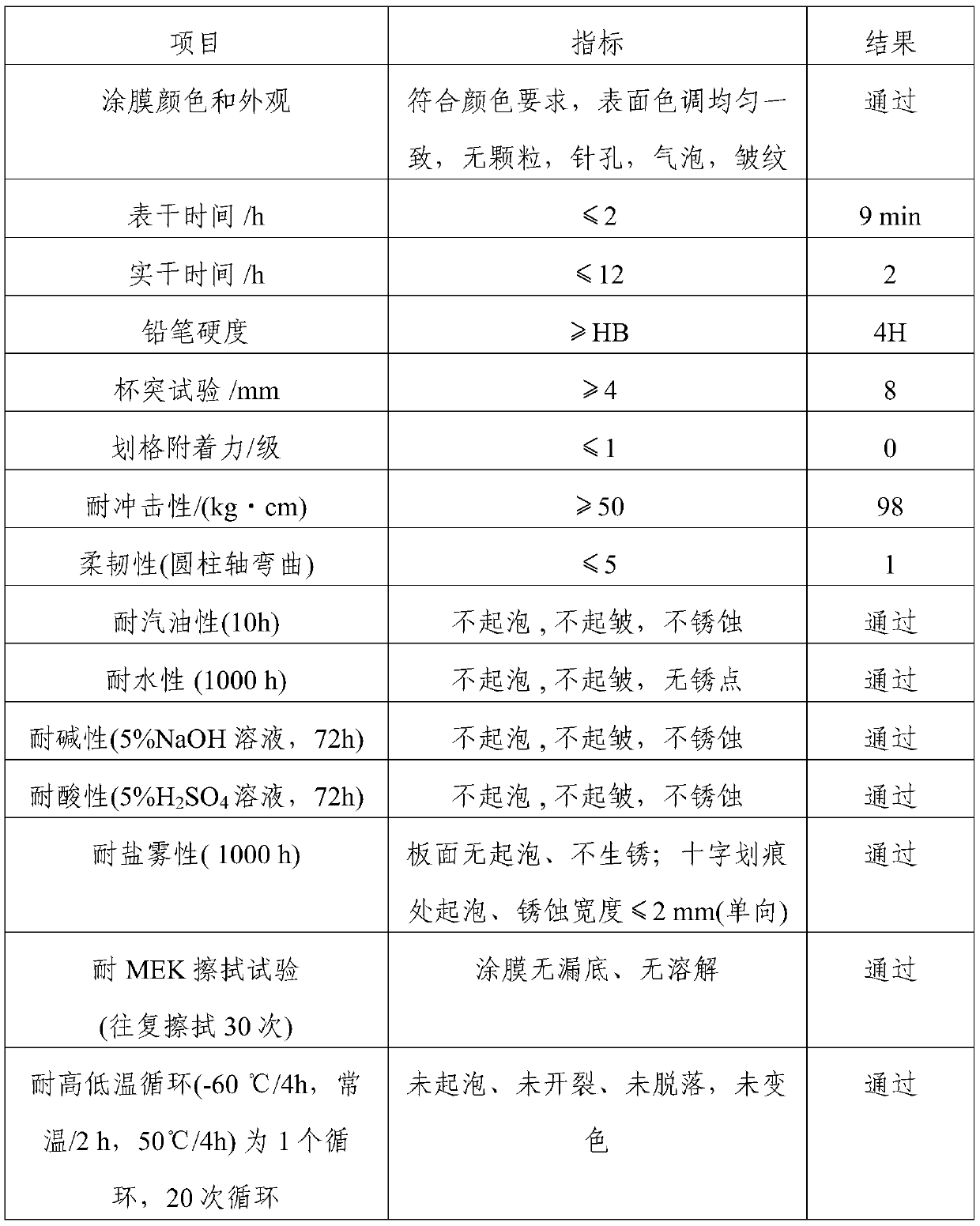

Embodiment 1

[0029] A high-performance two-component epoxy primer for rail transit, comprising component A and component B, the weight ratio of component A and component B is 10:2.5;

[0030] Component A consists of the following components by weight: 8 parts of epoxy resin 604, 18 parts of epoxy resin 828, 1.1 parts of graphene, 0.8 parts of epoxy silane coupling agent modified nano-silica, 8 parts of talcum powder, 10 parts of wet sericite powder, 12 parts of rutile titanium dioxide, 5 parts of carbon black, 10 parts of zinc calcium modified aluminum tripolyphosphate, 4 parts of zinc phosphomolybdate, 0.35 parts of thixotropic agent, 1.2 parts of wetting and dispersing agent BYK9077 0.3 parts of leveling agent BYK-310, 0.4 parts of defoamer BYK025, 18 parts of mixed solvent;

[0031] Component B consists of the following components by weight: 15 parts of cashew nut shell oil modified phenalkamine resin, 32 parts of cardanol modified polyamide resin, 36 parts of xylene, 24 parts of n-buta...

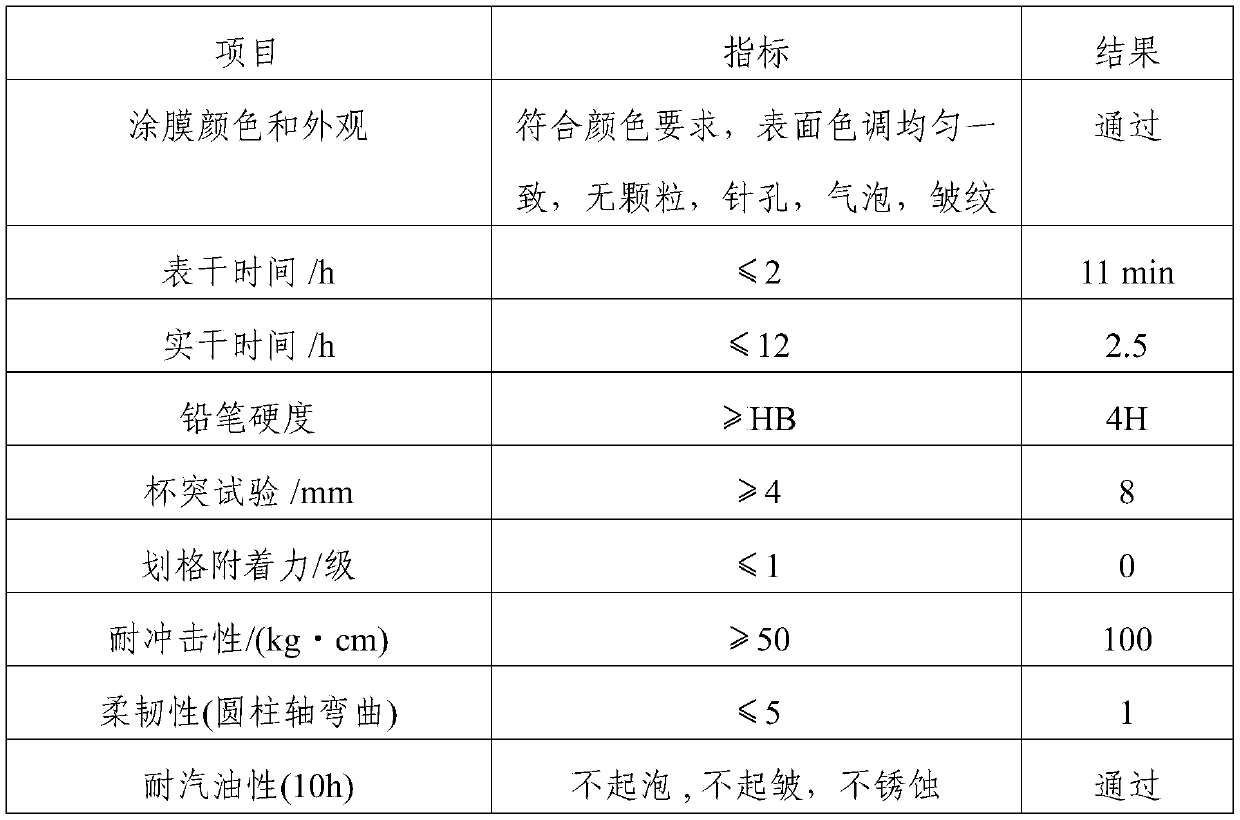

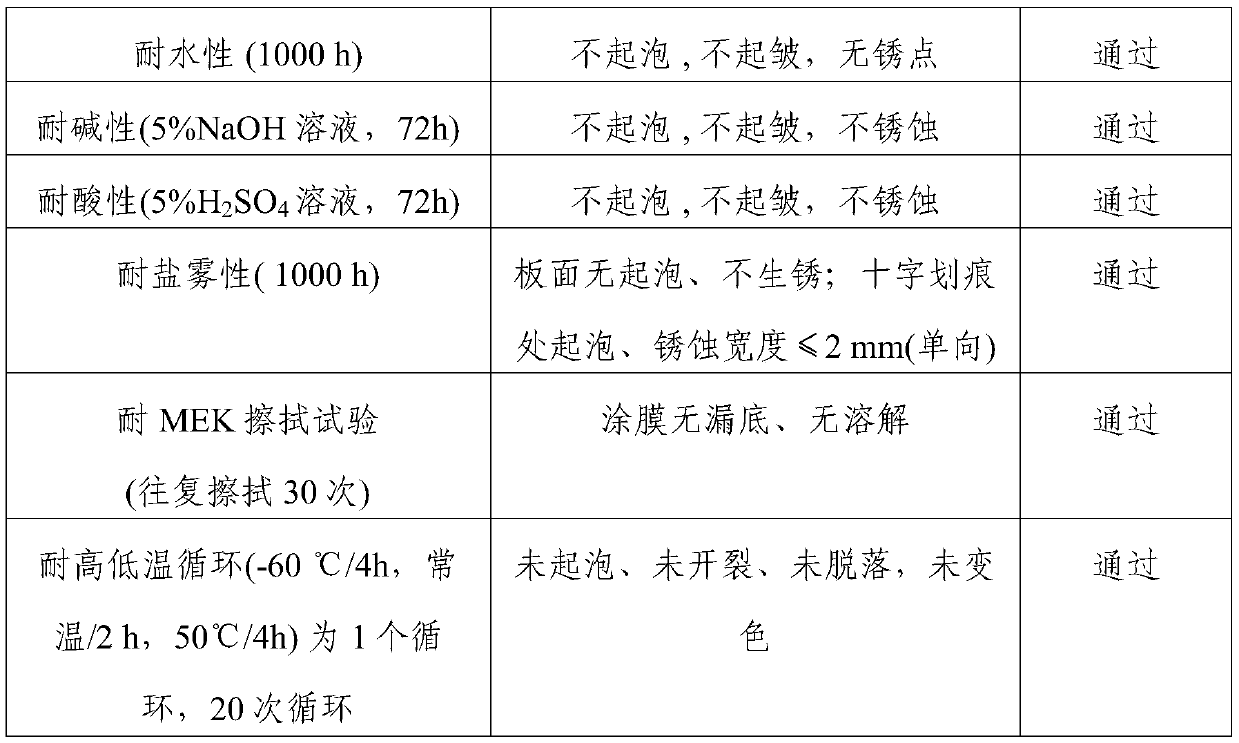

Embodiment 2

[0038] A high-performance two-component epoxy primer for rail transit, comprising component A and component B, the weight ratio of component A and component B is 10:2.8;

[0039]Component A is composed of the following components by weight: 10 parts of epoxy resin E-20, 15 parts of epoxy resin 862, 1 part of graphene, 1.5 parts of epoxy silane coupling agent modified nano-silica, rectorite powder 5 parts, 10 parts of wet sericite powder, 6 parts of precipitated barium sulfate, 5 parts of rutile titanium dioxide pigment, 9 parts of iron oxide red, 8 parts of zinc calcium modified aluminum tripolyphosphate, 5 parts of zinc phosphomolybdate, 0.3 parts of thixotropic agent, 1.2 parts of wetting and dispersing agent BYK9076, 0.25 parts of leveling agent BYK-354, 0.5 parts of defoamer BYK025, 17 parts of mixed solvent;

[0040] Component B consists of the following components by weight: 27 parts of cashew nut shell oil modified phenalkamine resin, 28 parts of cardanol modified polya...

Embodiment 3

[0048] A high-performance two-component epoxy primer for rail transit, comprising component A and component B, the weight ratio of component A and component B is 10:2.6;

[0049] Component A is composed of the following components by weight: 7 parts of epoxy resin 607, 19 parts of epoxy resin E-44, 0.5 parts of graphene, 0.3 parts of epoxy silane coupling agent modified nano-silica, rectorite powder 10 parts, 10 parts of precipitated barium sulfate, 2 parts of carbon black, 15 parts of rutile titanium dioxide, 1 part of phthalocyanine blue, 11 parts of zinc calcium modified aluminum tripolyphosphate, 3 parts of zinc phosphomolybdate, 0.5 parts of thixotropic agent , 1 part of wetting and dispersing agent BYK9077, 0.2 part of leveling agent BYK-310, 0.3 part of defoamer BYK025, 16 parts of mixed solvent;

[0050] Component B consists of the following components by weight: 30 parts of cashew nut shell oil modified phenalkamine resin, 25 parts of cardanol modified polyamide resin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com