Low-toxicity solid-liquid mixed authigenic acid system and high-temperature carbonate reservoir acidification method

A solid-liquid mixing, self-generating acid technology, applied in chemical instruments and methods, mining fluids, earth-moving drilling, etc. Erosion distance, easy to carry and transport, and the effect of reducing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

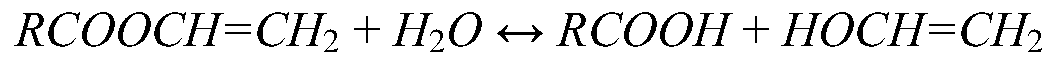

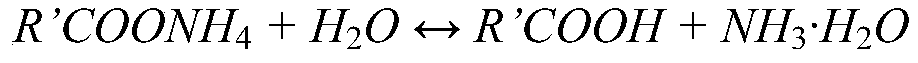

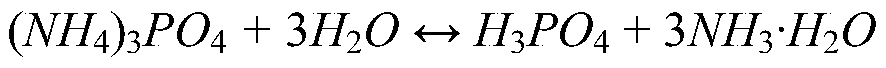

Method used

Image

Examples

Embodiment 1

[0043] A low-toxic solid-liquid mixed self-generating acid system includes a liquid system and a solid tablet; the liquid system is a mixed aqueous solution of vinyl acetate and vinyl formate, and the mass fractions are 4% and 6% respectively.

[0044] The solid tablet is made of a tablet core composed of weak acid ammonium salt, guar gum, sucrose and magnesium stearate through film coating. The mass percentages of the weak acid ammonium salt, guar gum, and sucrose are respectively 70%, 15%, and 9%, and the balance is magnesium stearate. Wherein, the weak acid ammonium salt is a mixture of ammonium phosphate and ammonium acetate in a mass ratio of 1:0.6.

[0045] Described solid tablet is prepared as follows:

[0046] According to the proportion, take weak acid ammonium salt and guar gum and place them in a container, stir for 5 minutes; add sucrose and magnesium stearate, mix and stir for 5 minutes, and then compact with a single-punch tablet machine to form a tablet core; a...

Embodiment 2

[0049] Embodiment 2: As described in Embodiment 1, the difference is:

[0050]The mass fractions of vinyl acetate and vinyl formate in the liquid system are 6% and 9%, respectively.

[0051] The solid tablet is made of a tablet core composed of weak acid ammonium salt, guar gum, sucrose and magnesium stearate through film coating. The mass percentages of the weak acid ammonium salt, guar gum, and sucrose are respectively 72%, 12%, and 10%, and the balance is magnesium stearate. Wherein, the weak acid ammonium salt is a mixture of ammonium phosphate and ammonium acetate in a mass ratio of 1:0.8.

Embodiment 3

[0052] Embodiment 3: As described in Embodiment 1, the difference is:

[0053] The liquid system is a mixed aqueous solution of vinyl formate and vinyl acetate, with mass fractions of 8% and 7% respectively.

[0054] The solid tablet is made of a tablet core composed of weak acid ammonium salt, guar gum, sucrose and magnesium stearate through film coating. The mass percentages of the weak acid ammonium salt, guar gum, and sucrose are respectively 68%, 13%, and 8%, and the balance is magnesium stearate. Wherein, the weak acid ammonium salt is a mixture of ammonium phosphate and ammonium formate in a mass ratio of 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com