A q345ns spiral submerged arc welded pipe for sulfuric acid dew point corrosion resistance and its manufacturing process

A dew point corrosion and submerged arc welded pipe technology, applied in the field of steel pipe manufacturing, can solve the problems of poor forming stability of large-diameter steel pipes and poor sulfuric acid corrosion resistance, and achieve the effects of inhibiting electrochemical reaction, improving passivation ability, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

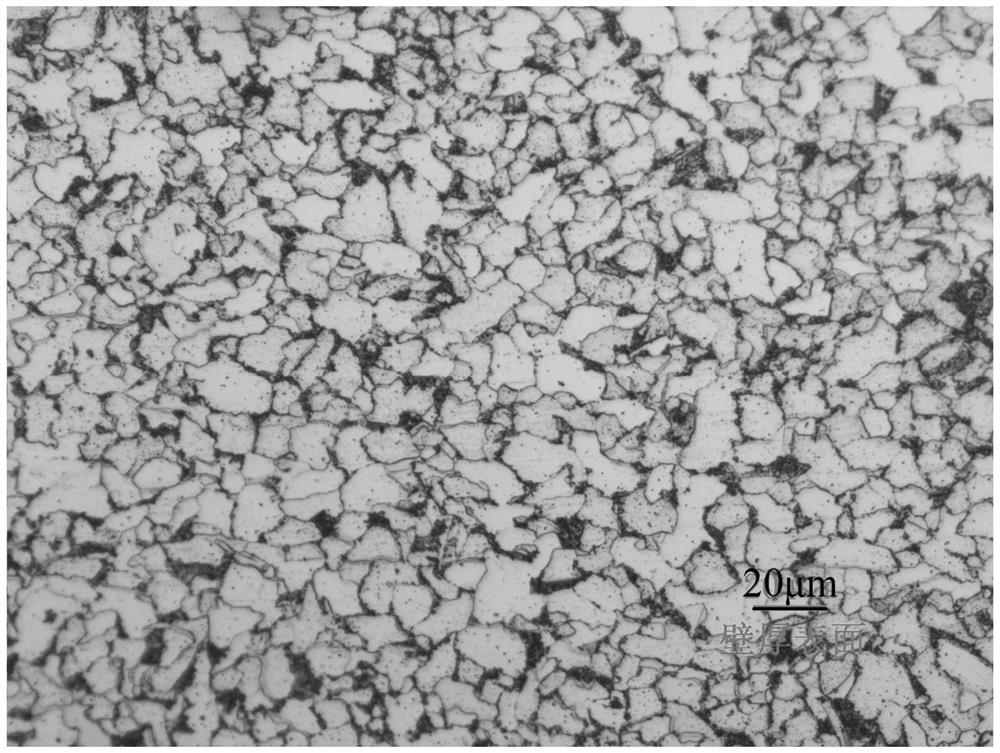

[0040] The embodiment of the present invention provides a Q345NS spiral submerged arc welded pipe for sulfuric acid dew point corrosion resistance. The coils used in the pipe include the following components in terms of mass percentage: C: 0.07%, Mn: 0.79%, Si: 0.32%, P: 0.017 %, S: 0.004%, Cu: 0.29%, Cr: 0.87%, Sb: 0.08%, Ni: 0.16%, Sn: 0.008%, B: 0.0003%, Ti: 0.02%, CE pcm : 0.18%, the rest is iron and unavoidable impurities.

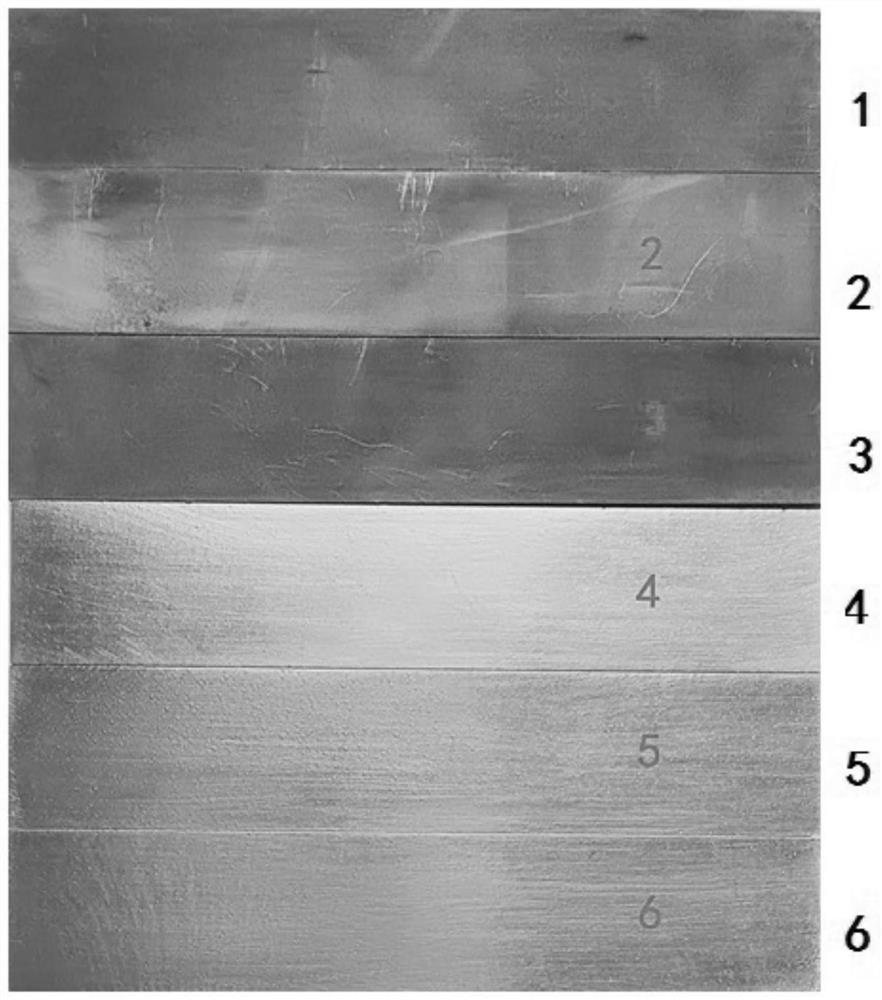

[0041] The above-mentioned coils are smelted in a converter and refined outside the furnace. During the continuous casting process, light reductions are used, combined with a reasonable controlled rolling and controlled cooling process. The specification is 12×1800mm, and the outer diameter of the steel pipe is 3020mm. Spiral submerged arc welded pipes, the manufacture of which includes decoiling, leveling, butt welding, edge milling, forming, welding, pipe cutting, ultrasonic inspection, pipe end chamfering and finished product inspection, wherein sa...

Embodiment 2

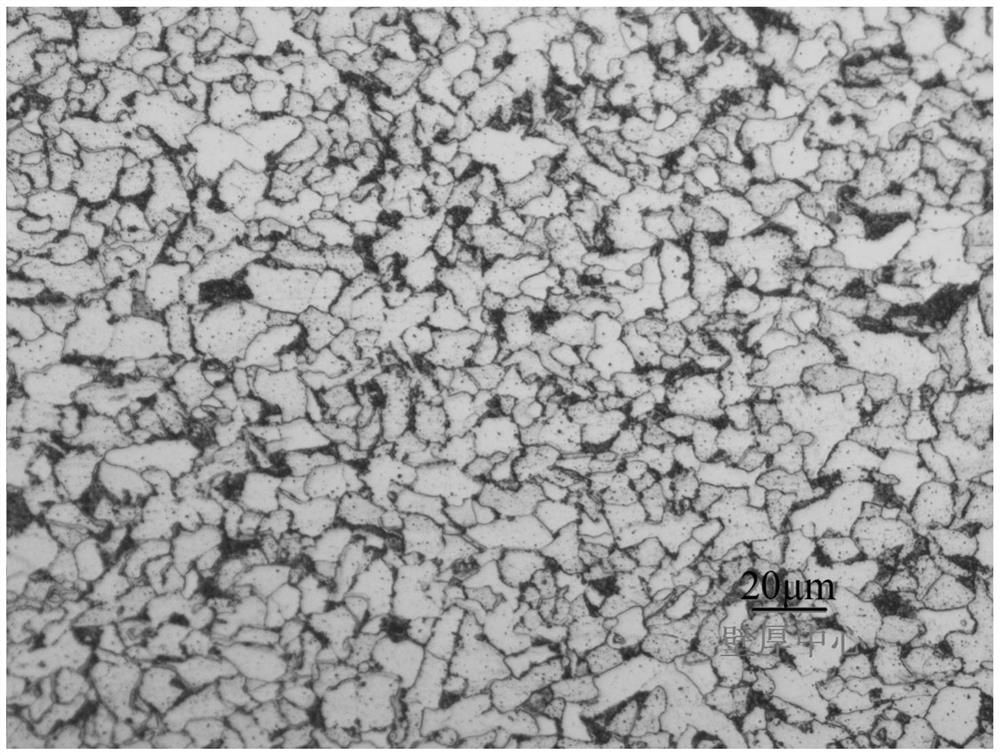

[0079] The embodiment of the present invention provides a Q345NS spiral submerged arc welded pipe for sulfuric acid dew point corrosion resistance. The coil used in it includes the following components in terms of mass percentage: C: 0.08%, Mn: 0.70%, Si: 0.40%, P: 0.015 %, S: 0.005%, Cu: 0.40%, Cr: 0.60%, Sb: 0.07%, Ni: 0.16%, Sn: 0.0010%, B: 0.0003%, Ti: 0.023%, CE pcm : 0.18%, the rest is iron and unavoidable impurities.

[0080]The above-mentioned coils are smelted in a converter and refined outside the furnace. In the continuous casting process, light reduction is used, and a reasonable controlled rolling and controlled cooling process is used to roll. Submerged arc welded pipes, the manufacture of which includes uncoiling, leveling, butt welding, milling operations, forming operations, welding operations, pipe cutting, ultrasonic inspection, pipe end chamfering and finished product inspection, wherein said forming operations are performed according to 79°12′ The forming...

Embodiment 3

[0089] The embodiment of the present invention provides a Q345NS spiral submerged arc welded pipe for sulfuric acid dew point corrosion resistance. The coils used in the pipe include the following components in terms of mass percentage: C: 0.06%, Mn: 1.20%, Si: 0.28%, P: 0.014 %, S: 0.005%, Cu: 0.20%, Cr: 1.00%, Sb: 0.06%, Ni: 0.15%, Sn: 0.015%, B: 0.0004%, Ti: 0.018%, CE pcm : 0.19%, the rest is iron and unavoidable impurities.

[0090] The above-mentioned coils are smelted in a converter and refined outside the furnace. In the continuous casting process, light reductions are used, and a reasonable controlled rolling and controlled cooling process is used to roll the coils. Q345NS spiral submerged arc welded pipe, its manufacturing method includes uncoiling, leveling, butt welding, milling process, forming process, welding process, pipe cutting, ultrasonic inspection, pipe end chamfering and finished product inspection, wherein the forming process is in accordance with 79 Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com