Biochar-chitosan compound as well as preparation method and application thereof

A technology of chitosan and biochar, applied in chemical instruments and methods, water pollutants, and other chemical processes, can solve the problem of unsatisfactory adsorption of azo dye-Congo red, high preparation cost, and poor stability of chitosan To achieve the effect of improving adsorption decolorization efficiency, increasing surface area, and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

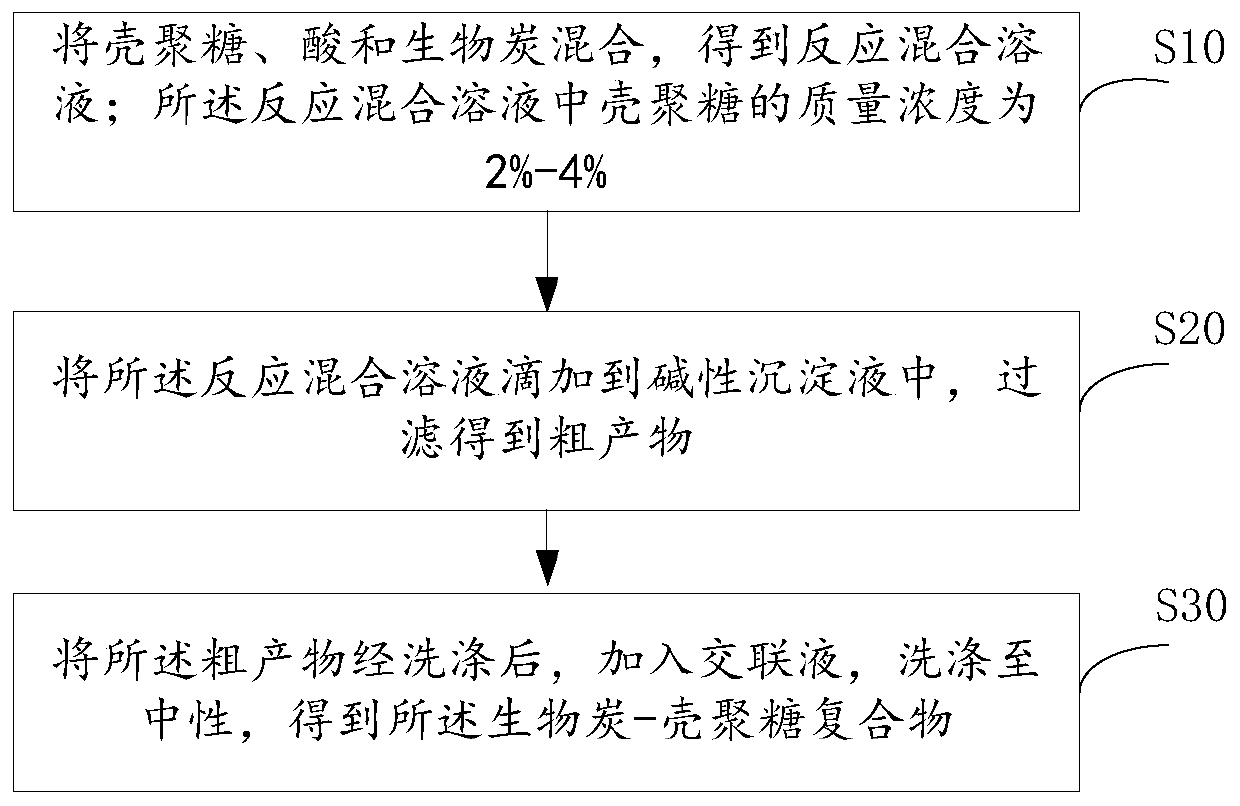

[0027] see figure 1 , figure 1 For the present invention discloses a flow chart of a preferred embodiment of a biochar-chitosan composite preparation method, as shown in the figure, the steps include:

[0028] S10, mixing chitosan, acid and biochar to obtain a reaction mixture solution; the mass concentration of chitosan in the reaction mixture solution is 2%-4%;

[0029] Biochar is a solid substance with high carbon content obtained by pyrolysis of carbon-containing organic matter under anaerobic or low-oxygen conditions. It is highly aromatized and chemically stable. Biochar has a huge specific surface area and numerous surface functional groups. It has the characteristics of rich pores, high stability, strong adsorption to dyes, rich resources, green and sustainable development. At the same time, because biochar has the characteristics of low price, high efficiency and little secondary pollution to the environment, it can reduce the adverse effects of organic pollutants a...

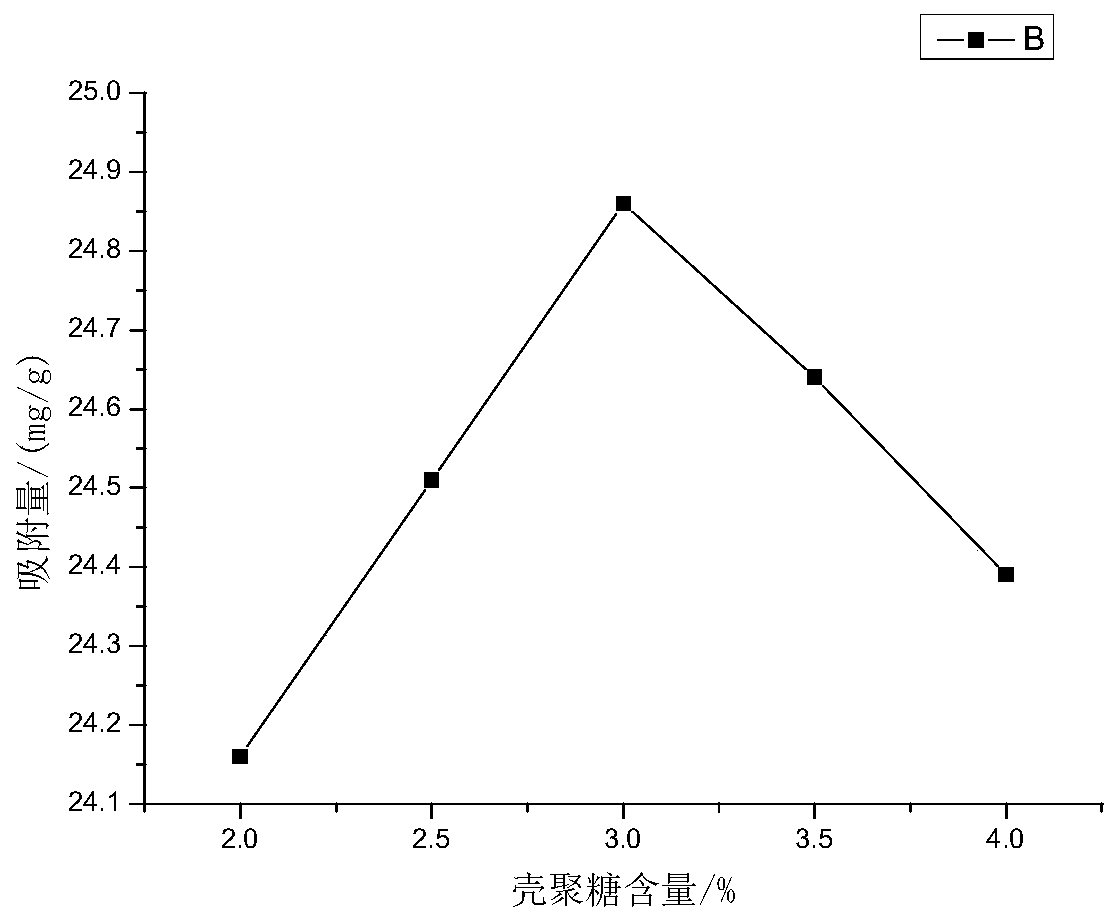

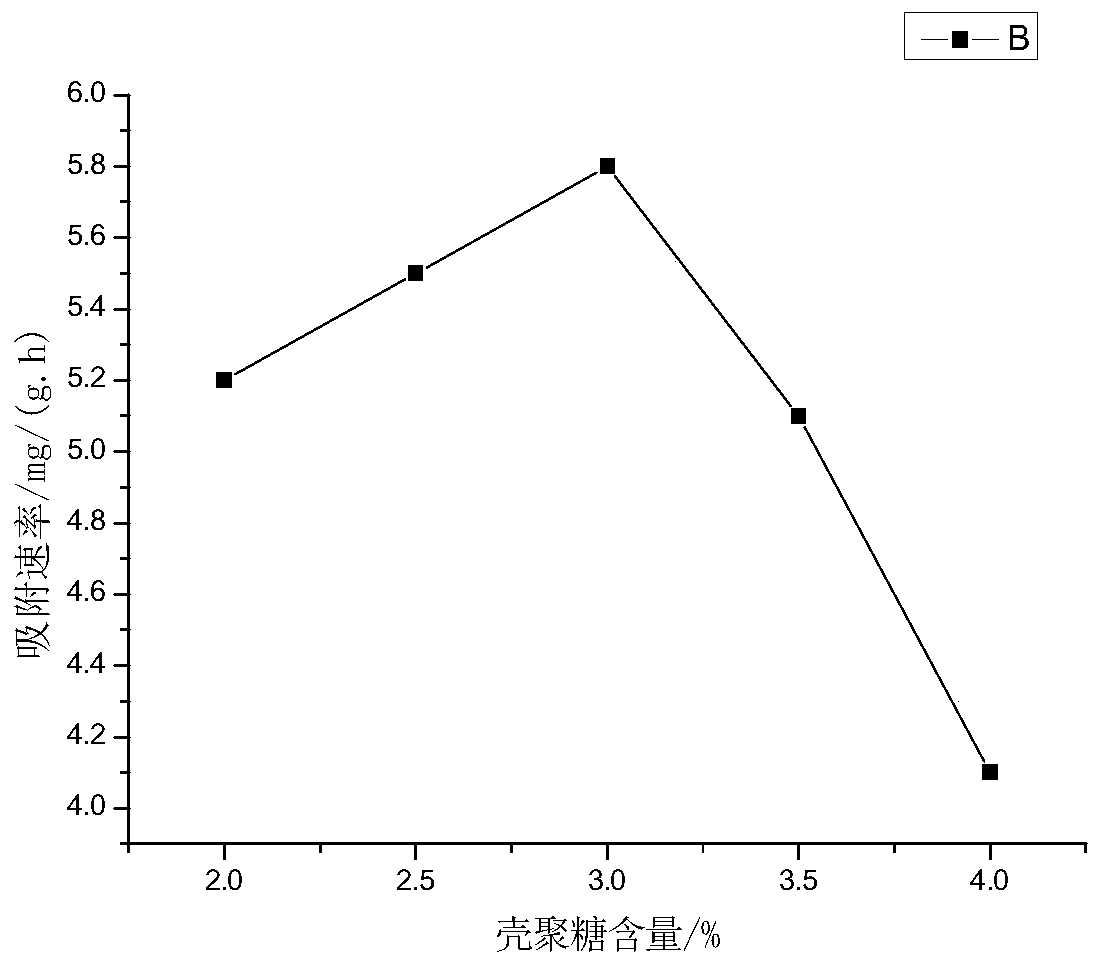

Embodiment 1

[0049] Weigh 2.0 g of chitosan powder, dissolve the chitosan with 100 mL of 2% acetic acid solution, stir for 30 minutes, and set aside. Add 0.5 g of biochar microparticles into the chitosan solution, and obtain a stable biochar-chitosan mixed solution system after the continuous vibration of the ultrasonic instrument for 30 minutes to make the system uniform. Add the above-mentioned chitosan solution dropwise into 200mL of alkaline precipitation medium (2mol / L NaOH and absolute ethanol ratio 4:1 mixture) through a syringe equipped with a No. 5 needle to prepare porous biochar-shell Polycane complex. Separate the complex by filtration, wash until neutral, add 80mL formaldehyde solution for cross-linking, wait for the chitosan complex to be cross-linked for 20 minutes, leave it sealed at room temperature for 12 hours, and then use deionized Wash with water until neutral to obtain the composite sample ③.

Embodiment 2

[0051] Weigh 2.5 g of chitosan powder, dissolve the chitosan with 100 mL of 2% acetic acid solution, stir for 30 minutes, and set aside. Add 0.5 g of biochar microparticles into the chitosan solution, and obtain a stable biochar-chitosan mixed solution system after the continuous vibration of the ultrasonic instrument for 30 minutes to make the system uniform. Add the above-mentioned chitosan solution dropwise into 200mL of alkaline precipitation medium (2mol / L NaOH and absolute ethanol ratio 4:1 mixture) through a syringe equipped with a No. 5 needle to prepare porous biochar-shell Polycane complex. Separate the complex by filtration, wash until neutral, add 80mL formaldehyde solution for cross-linking, wait for the chitosan complex to be cross-linked for 20 minutes, leave it sealed at room temperature for 12 hours, and then use deionized Wash with water until neutral to obtain the composite sample ④.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com