Heat treatment method for improving dielectric constant of insulating medium

A heat treatment method and a technology of dielectric constant, which are applied to insulators, circuits, electrical components, etc., can solve the problem of uninvolved dielectric constant, and achieve the effect of expanding the amorphous area, reducing the difficulty of the process, and reducing the size of the electric domain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A heat treatment method for improving the dielectric constant of an insulating medium, comprising the following steps;

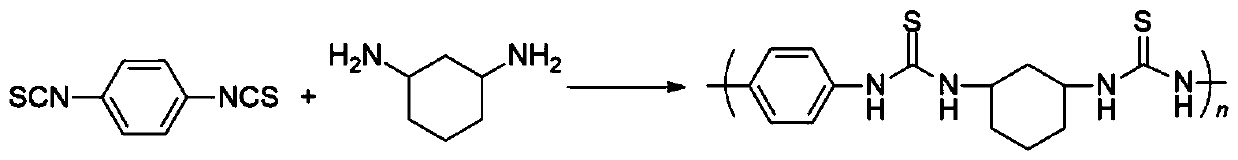

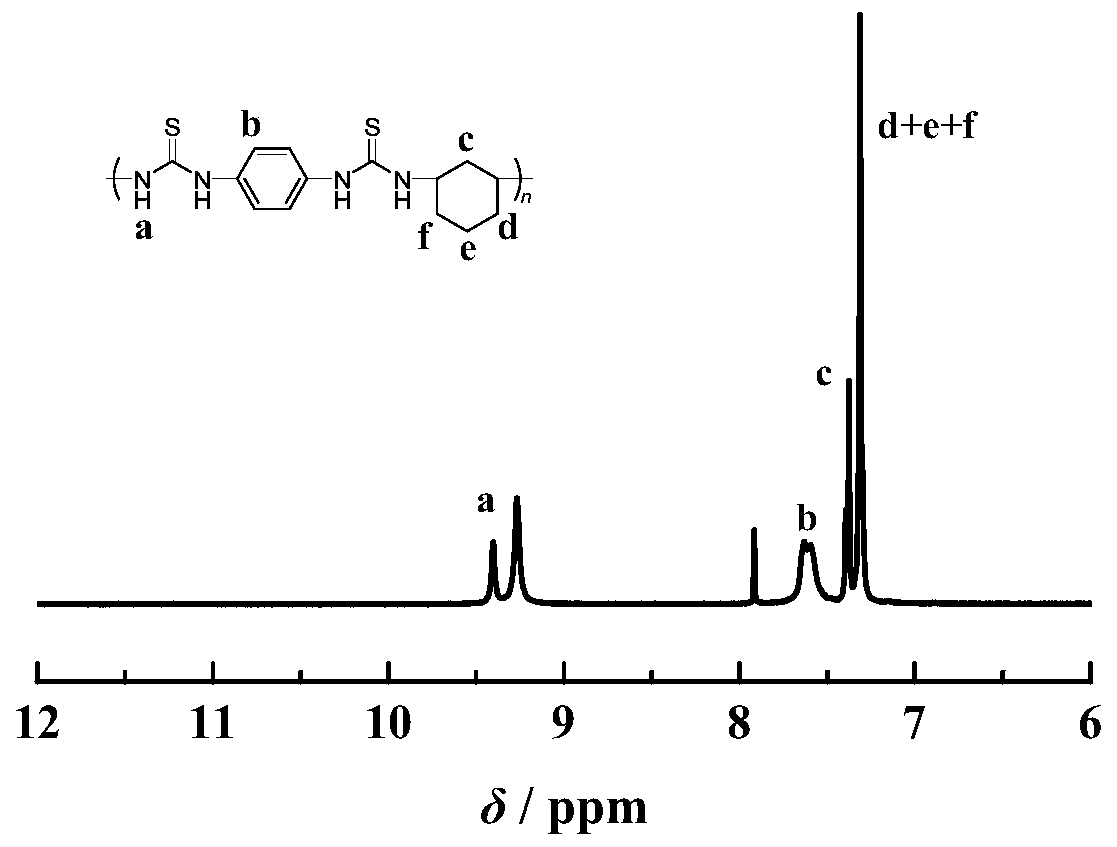

[0041] 1) 2mmol of 1,4-phenylene diisothiocyanate was completely dissolved in 4mL of 4mL N,N-dimethylacetamide (DMAc), 2mmol of 1,3-cyclohexanediamine was added to the above solution, under nitrogen atmosphere , Reaction at room temperature for 24 hours. The reaction solution was slowly added into 100 mL of methanol, and a white fibrous insoluble polymer was precipitated. The polymer was collected by filtration, and placed under vacuum at room temperature for 2 hours to finally obtain a dry fibrous alicyclic polythiourea polymer.

[0042] 2) Dissolve 50mg polythiourea polymer in 1mL DMAc, stir until fully dissolved, filter to remove impurities, and use casting method to drop the clear polythiourea solution on the cleaned glass sheet, and place it in hot Treat at 60°C on the stage for 1 hour, then increase the temperature of the hot stage to 80°C for ...

Embodiment 2

[0045] The difference from the embodiment is that the heat treatment temperature is 110° C., and the other is the same as the embodiment, and the obtained polythiourea film is recorded as sample ②.

Embodiment 3

[0047] The difference from the example is that the heat treatment temperature is 120° C., and the other is the same as the example, and the obtained polythiourea film is recorded as sample ③.

[0048]see Figure 4 ,from Figure 4 It can be seen that after heat treatment of the alicyclic polythiourea sample for 2 hours, the dielectric constant reaches the maximum value of 9.98.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com