Sintering flue gas activated carbon desulfurization process acid-making wastewater recycling system and method thereof

A technology for sintering flue gas and desulfurization process, which is applied in chemical instruments and methods, inorganic chemistry, ammonia compounds, etc., to achieve the effect of small footprint, no chemical use cost, and good separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

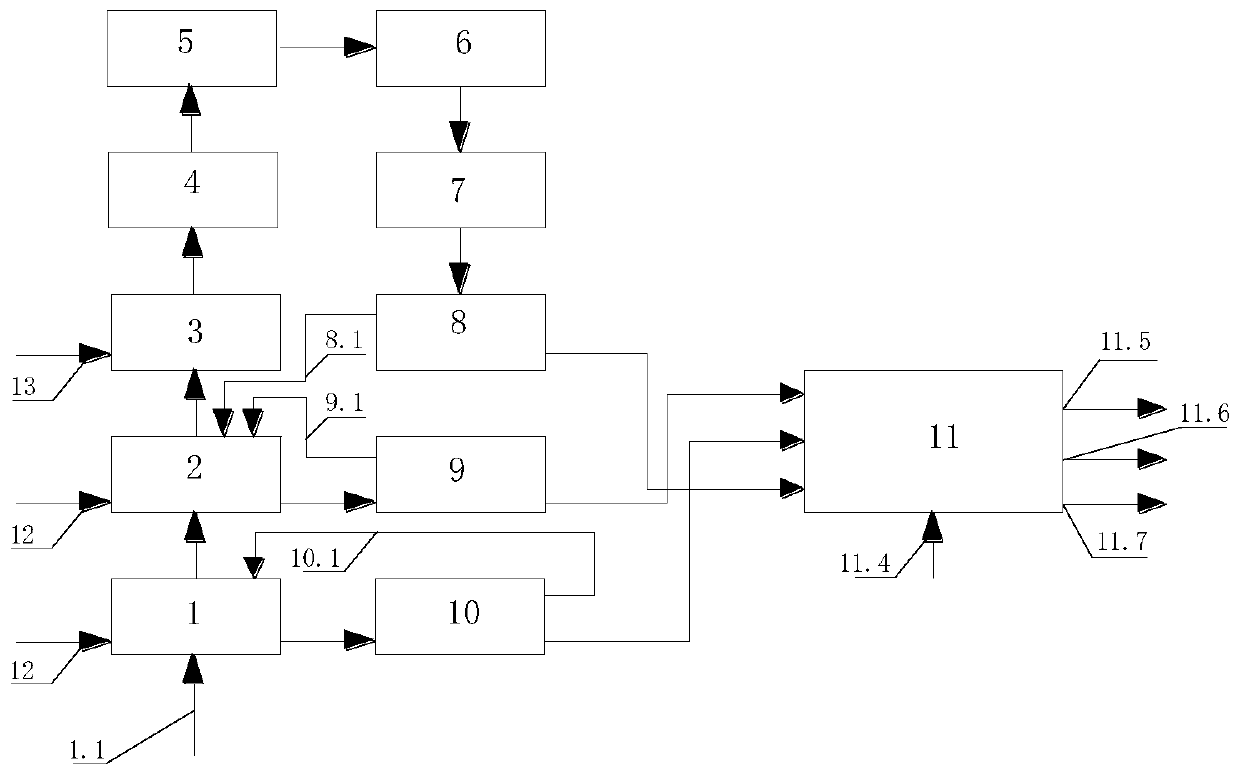

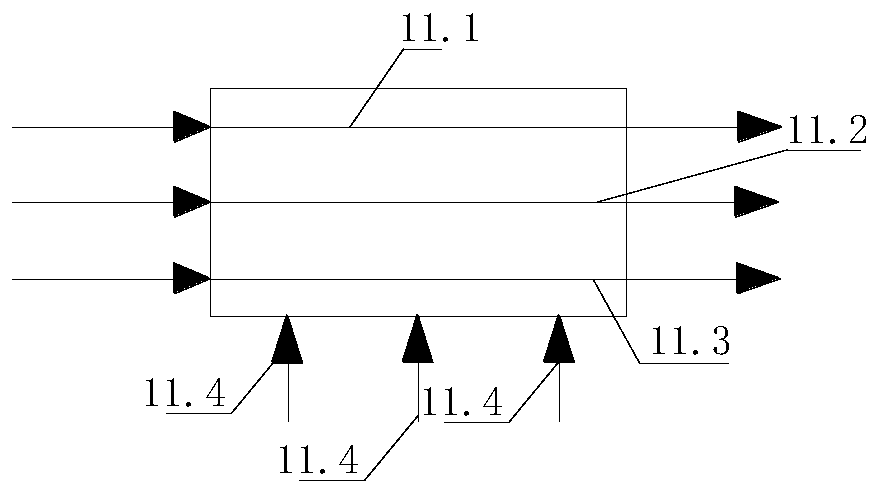

[0037] Such as Figure 1~2 The acid waste water recycling system of the sintering flue gas activated carbon desulfurization process includes a primary reaction tank 1, which is connected to a secondary reaction tank 2, a tertiary reaction tank 3, and a preheater in sequence through a main line. 4. Rising film heater 5, vacuum evaporator 6, crystallizer 7, centrifuge 8 and multi-layer fluidized bed dryer 11, primary reaction tank 1 is respectively connected with ammonia water pipe 12 and acid waste water pipe 1.1, secondary The reaction tank 2 is connected with an ammonia water pipe 12, the third-stage reaction tank 3 is connected with an aeration pipe or a double-ammonia water pipe 13, and the first-stage reaction tank 1 is connected with a first-stage sludge dehydrator 10 and a multi-layer fluidization pipe in turn through a first-stage branch pipe. Bed dryer 11; primary sludge dehydrator 10 communicates with primary reaction tank 1 through primary return pipe 10.1.

[0038]...

Embodiment 2

[0042] A sintering flue gas activated carbon desulfurization plant:

[0043] Acid wastewater: pH is -1, acid content is 4.08%, SO 4 2- content 6328mg / L, ammonia nitrogen content 300mg / L, suspended matter content 6486mg / L, Fe content 130mg / L, Pb content 0.8mg / L, As content 0.5mg / L, Ni content 0.2mg / L, Hg content 0.4mg / L L, Cr content 0.1mg / L.

[0044] A method for recycling the acid-making wastewater of the sintering flue gas activated carbon desulfurization process acid-making wastewater comprises the following steps:

[0045] 1) The acid wastewater is pretreated first,

[0046] a. In the primary reaction tank 1, the concentration of 15% ammoniacal liquor is introduced, and the ammoniacal liquor and the acid waste water are mixed evenly with a stirrer, and the pH value of the waste water is detected to reach 6.5, then the stirring and ammoniacal liquor addition are stopped, and the reaction tank is allowed to settle for 5 minutes. Make the activated carbon powder in the su...

Embodiment 3

[0056] A sintering flue gas activated carbon desulfurization plant:

[0057] Acid wastewater: pH -0.8, acid content 4.92%, SO 4 2- content 9328mg / L, ammonia nitrogen content 350mg / L, suspended matter content 7486mg / L, Fe content 150mg / L, Pb content 0.9mg / L, As content 0.4mg / L, Ni content 0.3mg / L, Hg content 0.3mg / L L, Cr content 0.1mg / L.

[0058] A method for recycling the acid-making wastewater of the sintering flue gas activated carbon desulfurization process acid-making wastewater comprises the following steps:

[0059] 1) The acid wastewater is pretreated first,

[0060] a. It is 12% ammoniacal liquor to feed concentration in the primary reaction tank 1, make ammoniacal liquor and acid making waste water mix evenly with agitator, detect waste water pH value and make reach 7, stop stirring and add ammoniacal liquor, make reaction tank static settling 8min, Make the activated carbon powder in the suspended matter in the waste water settle down, enter the first-stage slud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com