Silicon carbide polymer precursor ceramic defect healing method

A precursor and polymer technology, which is applied in the field of silicon carbide polymer precursor ceramic defect healing, can solve the problems of complicated operation, unfavorable promotion and application, and high equipment requirements, and achieves the effect of simple process, industrialized production, and fewer internal defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Dissolve 1g polycarbosilane (PCS) powder, 1mL vinyltriethoxysilane (VTES) and 0.5mL castor catalyst in 20mL xylene to obtain a xylene solution, and disperse 0.01g GO powder in 20ml Aqueous solution in pure water;

[0029] 2. Mix the xylene solution and the aqueous solution, heat the mixed solution in a 60°C water bath and stir it with a magnetic stirrer, keep it warm for 30 minutes, let it stand after the reaction, take the upper liquid and spin evaporate it and grind it to obtain the precursor PVG powder;

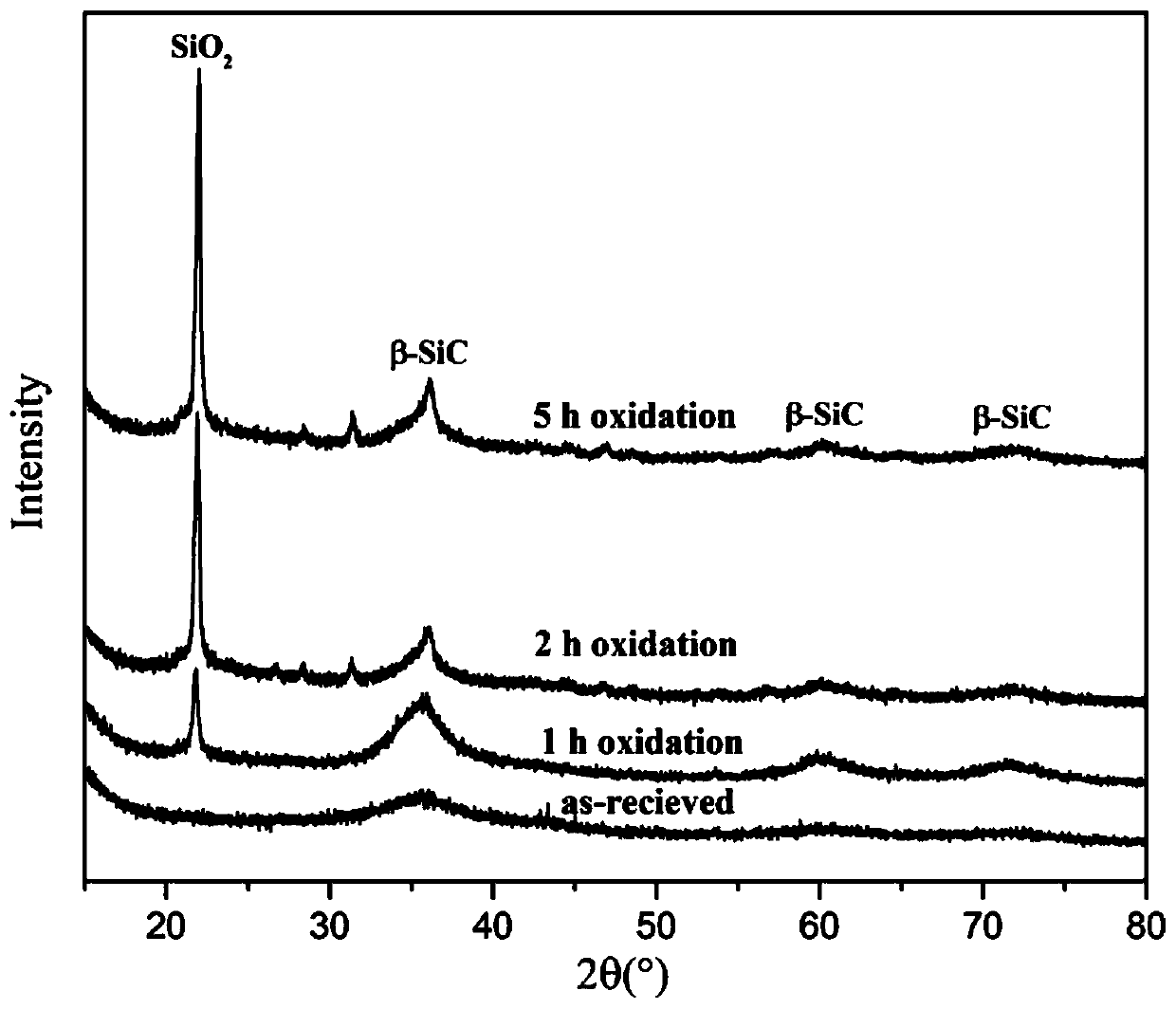

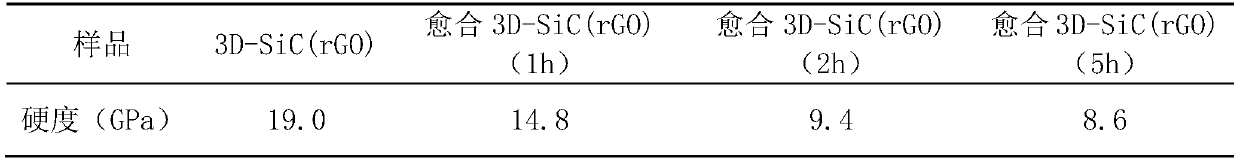

[0030] 3. The SiC (rGO) green body was obtained by compression molding PVG powder, which was sintered at 1200°C in an atmosphere tube furnace under an argon atmosphere, kept for 30 minutes, and black 3D-SiC (rGO) was obtained after cooling in the furnace ceramics;

[0031] 4. Immerse the 3D-SiC(rGO) ceramics in the LPCS precursor for 24h, take it out and dry it, and then put it in N 2 Pyrolysis at 1200°C in the atmosphere, holding time 1h, and repeating 5 times...

Embodiment 2

[0034] 1. Dissolve 1g of PCS powder, 1mL of VTES and 0.5mL of Castel catalyst in 20mL of xylene to obtain a xylene solution, and disperse 0.01g of GO powder in 20ml of purified water to obtain an aqueous solution;

[0035]2. Mix the xylene solution and the aqueous solution, heat the mixed solution in a 60°C water bath and stir it with a magnetic stirrer, keep it warm for 30 minutes, let it stand after the reaction, take the upper liquid and spin evaporate it and grind it to obtain the precursor PVG powder;

[0036] 3. The SiC (rGO) green body was obtained by compression molding PVG powder, which was sintered at 1200°C in an atmosphere tube furnace under an argon atmosphere, kept for 30 minutes, and black 3D-SiC (rGO) was obtained after cooling in the furnace ceramics;

[0037] 4. Immerse the 3D-SiC(rGO) ceramics in the LPCS precursor for 24h, take it out and dry it, and then put it in N 2 Pyrolysis at 1200°C in the atmosphere, holding time 1h, and repeating 5 times to obtain ...

Embodiment 3

[0040] 1. Dissolve 1g polycarbosilane (PCS) powder, 1mL vinyltriethoxysilane (VTES) and 0.5mL castor catalyst in 20mL xylene to obtain a xylene solution, and disperse 0.01g GO powder in 20ml Aqueous solution in pure water;

[0041] 2. Mix the xylene solution and the aqueous solution, heat the mixed solution in a 60°C water bath and stir it with a magnetic stirrer, keep it warm for 30 minutes, let it stand after the reaction, take the upper liquid and spin evaporate it and grind it to obtain the precursor PVG powder;

[0042] 3. The SiC (rGO) green body was obtained by compression molding PVG powder, which was sintered at 1200°C in an atmosphere tube furnace under an argon atmosphere, kept for 30 minutes, and black 3D-SiC (rGO) was obtained after cooling in the furnace ceramics;

[0043] 4. Immerse the 3D-SiC(rGO) ceramics in the LPCS precursor for 24h, take it out and dry it, and then put it in N 2 Pyrolysis at 1200°C in the atmosphere, holding time 1h, and repeating 5 times...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com