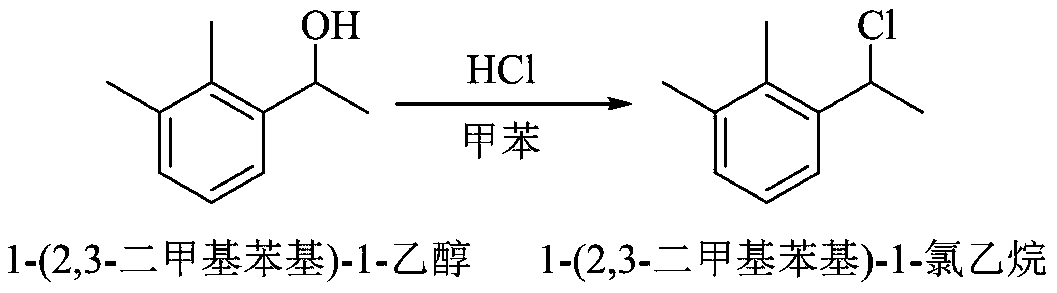

Green production method of 1-(2, 3-dimethylphenyl)-1-chloroethane

A dimethylphenyl, green production technology, applied in chemical instruments and methods, halogenated hydrocarbon preparation, organic chemistry and other directions, can solve problems such as unfavorable environmental protection and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The reaction product is qualitatively and quantitatively detected by high performance liquid chromatography: using octadecylsilane bonded silica gel as a filler (4.6mm×150mm, 5μm or a chromatographic column with equivalent performance), with 0.02mol / L disodium hydrogen phosphate solution (Adjust the pH value to 6.3 with phosphoric acid)-acetonitrile (75:25) as the mobile phase; the detection wavelength is 220nm, and the injection volume is 20 μl.

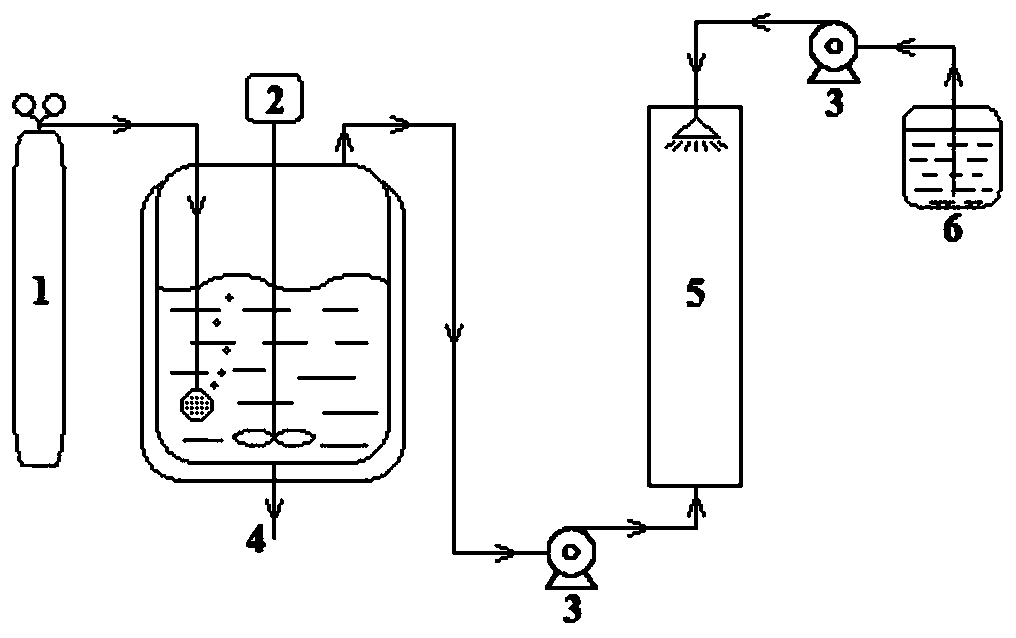

[0020] 1-(2,3-Dimethylphenyl)-1-ethanol and hydrogen chloride are passed into the 1-(2,3- In the reaction kettle of dimethylphenyl)-1-ethanol, heat it to the reaction temperature of 70°C, and vigorously stir the reaction for 5 hours. The hydrogen chloride produced in the reaction is extracted from the top of the reaction kettle and pumped into the bottom of the absorption tower. The flow rate is pumped into potassium hydroxide solution to absorb hydrogen chloride gas. The reaction solution was discharged from the bottom of t...

Embodiment 2

[0022] Reaction product qualitative and quantitative detection method and operation are all the same as in Example 1, and the implementation steps of changing the reactant molar proportion and each operating parameter are as follows:

[0023] 1-(2,3-Dimethylphenyl)-1-ethanol and hydrogen chloride are passed into the 1-(2,3- In the reaction kettle of dimethylphenyl)-1-ethanol, heat it to the reaction temperature of 50°C, and stir vigorously for 3 hours. The hydrogen chloride produced in the reaction is extracted from the top of the reaction kettle and pumped into the bottom of the absorption tower. The flow rate is pumped into the sodium hydroxide solution to absorb hydrogen chloride gas. The reaction solution was discharged from the bottom of the kettle, and after atmospheric distillation, high-purity 1-(2,3-dimethylphenyl)-1-chloroethane could be obtained with a yield of 87.6%.

Embodiment 3

[0025] Reaction product qualitative and quantitative detection method and operation are all the same as in Example 1, and the implementation steps of changing the reactant molar proportion and each operating parameter are as follows:

[0026] 1-(2,3-Dimethylphenyl)-1-ethanol and hydrogen chloride are passed into the 1-(2,3- In the reaction kettle of dimethylphenyl)-1-ethanol, heat it to the reaction temperature of 30°C, and vigorously stir the reaction for 1 hour. The hydrogen chloride produced in the reaction is extracted from the top of the reaction kettle and pumped into the bottom of the absorption tower. The flow rate is pumped into potassium carbonate solution to absorb hydrogen chloride gas. The reaction solution was released from the bottom of the kettle, and after atmospheric distillation, high-purity 1-(2,3-dimethylphenyl)-1-chloroethane could be obtained with a yield of 88.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com