ZIF-67 zeolite imidazate skeleton-based composite electrocatalyst, preparation method thereof, zinc-air battery positive electrode and zinc-air battery

A technology of ZIF-67 and zeolite imidazolate, applied in the field of electrochemical energy storage, can solve problems such as high cost, and achieve the effect of excellent electrochemical performance and enrichment of catalytic sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

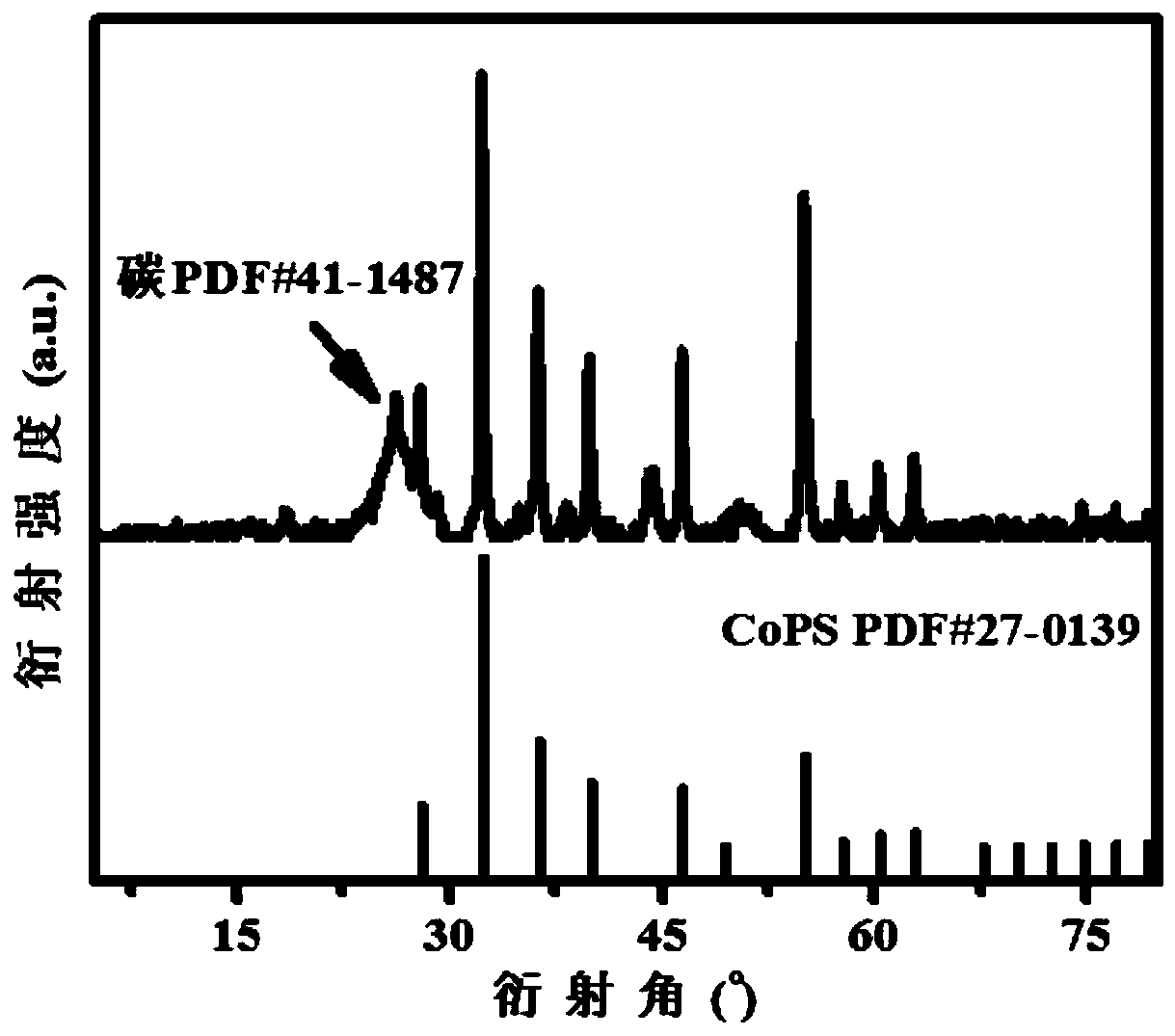

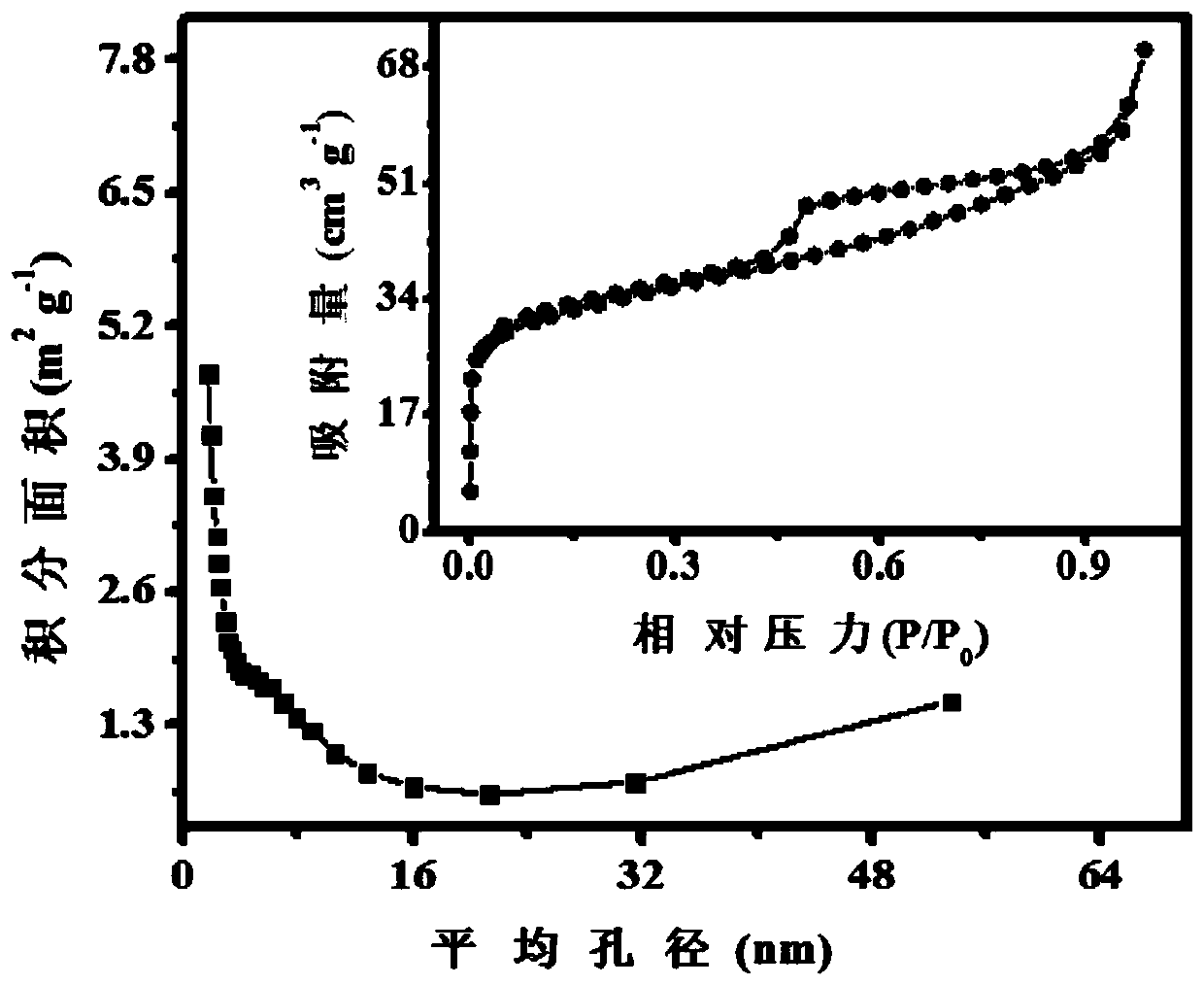

[0022] Some embodiments of the present invention provide a method for preparing a ZIF-67 zeolite imidazolate skeleton-based composite electrocatalyst, which includes: sulfurizing and / or phosphating the carbonized ZIF-67 zeolite imidazolate skeleton under an inert atmosphere . That is, the carbonized ZIF-67 zeolite imidazolate framework is separately subjected to sulfurization treatment or phosphating treatment under an inert atmosphere, or the carbonized ZIF-67 zeolite imidazolate framework is subjected to both sulfurization treatment and phosphating treatment under an inert atmosphere.

[0023] The inventors found that in the prior art, the cost of noble metal electrocatalysts is high, while the redox kinetics of non-noble metal electrocatalysts are slow. Based on this, the inventors improved the composite The performance of the material, the zeolite imidazolate framework formed by periodic structural unit links-67 serves as an in situ composite template, and its tunable pore...

Embodiment 1

[0055] The preparation method of a kind of ZIF-67 zeolite imidazolate skeleton-based composite electrocatalyst provided by this embodiment comprises the following steps:

[0056] (1) make ZIF-67 zeolite imidazolate framework material;

[0057] Under the condition of magnetic stirring, 4mmol Co(NO 3 ) 2 ·6H 2 O was dissolved in 100mL of anhydrous methanol to form a magenta clear solution A; 16mmol 2-methylimidazole was dissolved in the above solution to form a purple solution B, and the solution B continued to be magnetically stirred to a purple emulsion; the prepared emulsion Aged for 24 hours, centrifuged at 3500 rad / min and washed 3 times to obtain a purple paste; dried the prepared purple paste in a blast oven at 60°C for 10 hours, and dried in a vacuum oven at 105°C 6h, ZIF-67 zeolite imidazolate skeleton was prepared;

[0058] (2) Grind the ZIF-67 zeolite imidazolate framework material prepared in step (1) in an agate mortar for 10 min, and anneal at 600 °C for 1 h in...

Embodiment 2

[0068] The preparation method of a kind of ZIF-67 zeolite imidazolate skeleton-based composite electrocatalyst provided by this embodiment comprises the following steps:

[0069] (1) make ZIF-67 zeolite imidazolate framework material;

[0070] Under the condition of magnetic stirring, 4mmol Co(NO 3 ) 2 ·6H 2 O was dissolved in 100mL of anhydrous methanol to form a magenta clear solution A; 16mmol 2-methylimidazole was dissolved in the above solution to form a purple solution B, and the solution B continued to be magnetically stirred to a purple emulsion; the prepared emulsion Aged for 24 hours, centrifuged at 3500 rad / min and washed 3 times to obtain a purple paste; dried the prepared purple paste in a blast oven at 60°C for 10 hours, and dried in a vacuum oven at 105°C 6h, ZIF-67 zeolite imidazolate skeleton was prepared;

[0071] (2) Grind the ZIF-67 zeolite imidazolate framework material prepared in step (1) in an agate mortar for 10 min, and anneal at 600 °C for 1 h in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com