Efficient environment-friendly black titanium dioxide-based photocatalyst and preparation method thereof

A technology of black titanium dioxide and photocatalyst, which is applied in the field of photocatalysis, can solve the problems of low photocatalytic quantum efficiency, low sunlight utilization rate, and inability to efficiently use sunlight, etc., and achieve simple preparation process, improve photocatalytic efficiency, and inhibit recombination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

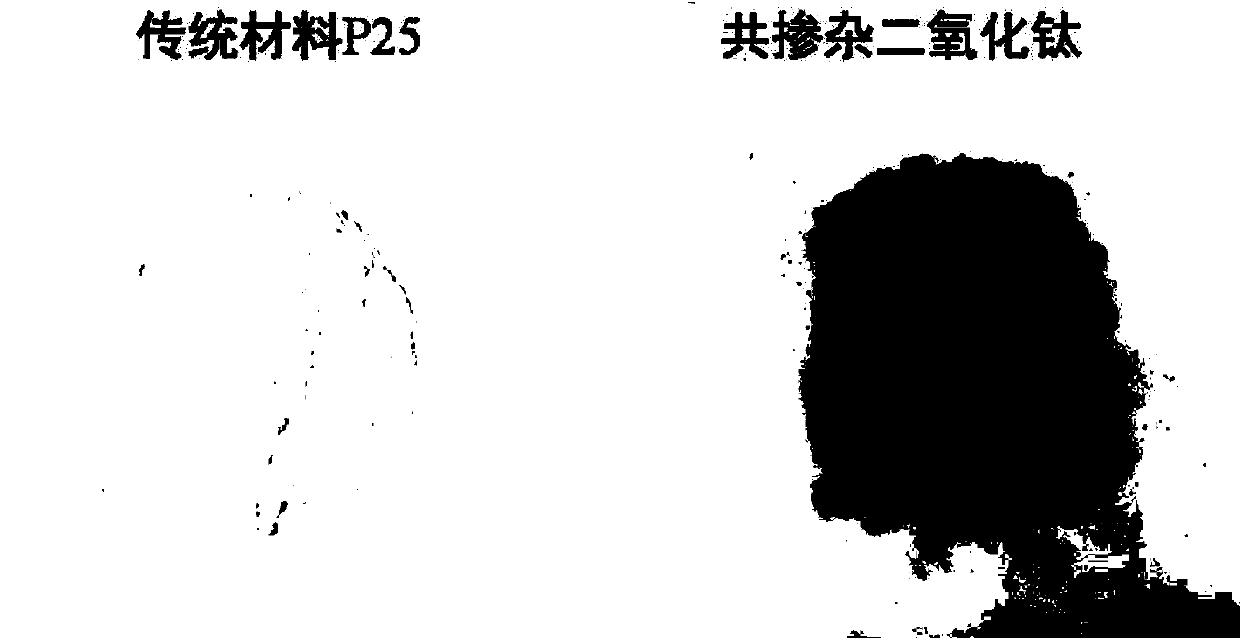

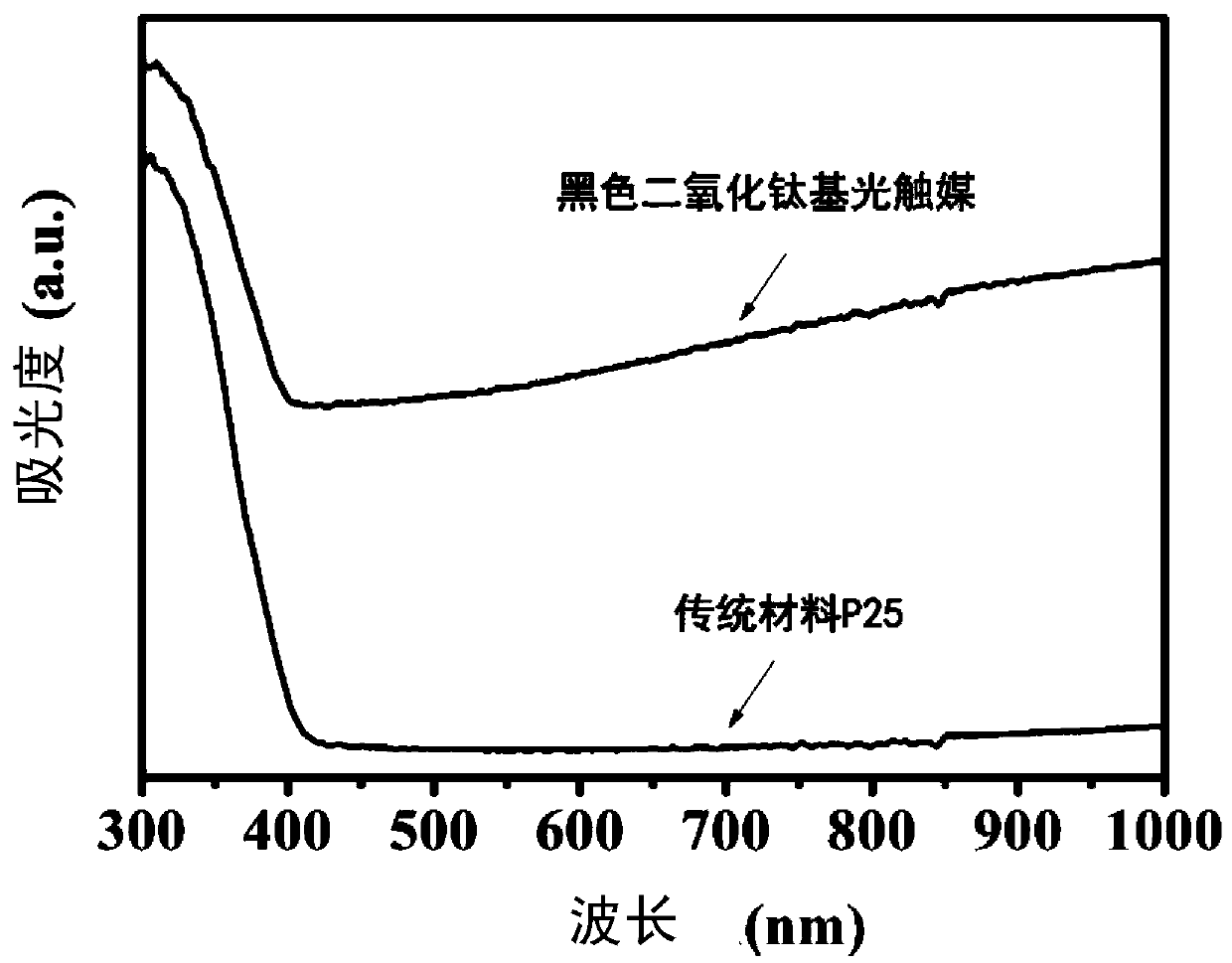

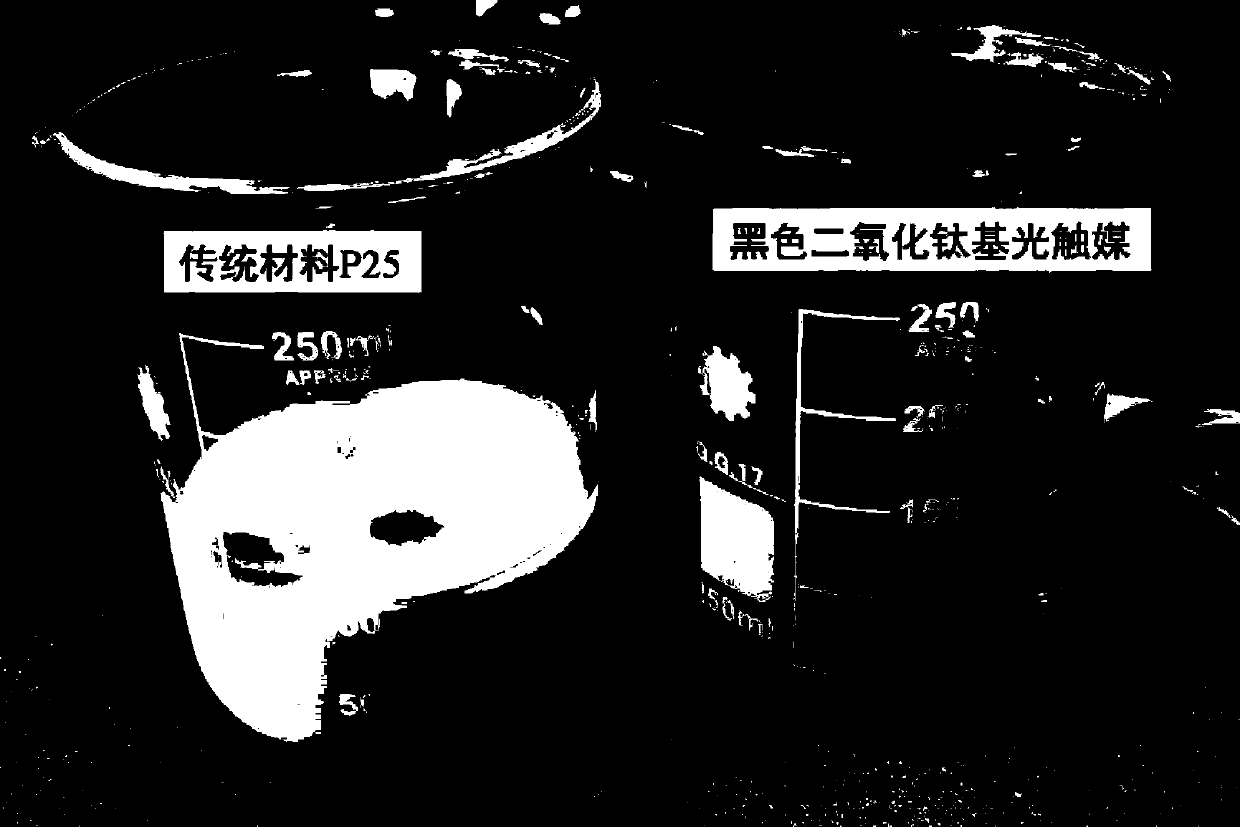

[0070] co-doped TiO 2 Preparation: (1) Add 4ml of glacial acetic acid, 0.18g of cobalt chloride, 0.08g of thiourea and 6ml of deionized water into 20ml of absolute ethanol, stir for 15 minutes, and adjust the pH to 3; (2) add 10ml of titanic acid Tetrabutyl ester was added dropwise in the ethanol (20ml) solution of acetylacetone (1ml), stirred rapidly for 20 minutes; (3) under ice-bath condition, (2) gained mixed solution was added dropwise in (1) gained mixed solution, and Stir rapidly during this process for 2 hours to obtain a yellow transparent sol, and then age for 10 hours to obtain a gel; (4) dry at a temperature of 100 ° C to obtain a light yellow powder; (5) place the obtained light yellow powder in Heat treatment at 500°C for 1.5h to finally obtain co-doped TiO 2 . figure 1 Co-doped TiO prepared for 2 Physical photo, different from the white color of traditional P25, the co-doped TiO prepared by this method 2 Black in appearance, indicating absorption of visible ...

Embodiment 2

[0073] co-doped TiO 2 Preparation: (1) Add 3ml of glacial acetic acid, 0.09g of cobalt chloride, 0.10g of nickel nitrate and 6ml of deionized water into 20ml of absolute ethanol, stir for 30 minutes, and adjust the pH to 4; (2) add 10ml of titanic acid Tetrabutyl ester was added dropwise in the ethanol (20ml) solution of acetylacetone (1ml), stirred rapidly for 15 minutes; (3) under ice-bath condition, the mixed solution obtained from (2) was added dropwise in the mixed solution obtained from (1), and Stir rapidly during this process for 2 hours to obtain a yellow transparent sol, and then age for 8 hours to obtain a gel; (4) dry at a temperature of 90°C to obtain a light yellow powder; (5) place the obtained light yellow powder in Under the condition of 500℃, the flow rate is 300sccm nitrogen protection heat treatment for 1.5h, and finally co-doped TiO 2 ;

[0074] co-doped TiO 2 Composite preparation with the supporting substrate: 0.4g co-doped TiO prepared above 2 and 0...

Embodiment 3

[0077] co-doped TiO 2 Preparation: (1) Add 4ml of glacial acetic acid, 0.01ml of phosphoric acid, 0.08g of thiourea and 6ml of deionized water into 20ml of absolute ethanol, stir for 60 minutes, and adjust the pH to 2; (2) add 10ml of tetrabutyl titanate Add the ester dropwise to the ethanol (20ml) solution of acetylacetone (1ml), and stir rapidly for 20 minutes; Stir rapidly during the process for 1 hour to obtain a yellow transparent sol, then age for 7 hours to obtain a gel; (4) dry at a temperature of 90°C to obtain a light yellow powder; (5) place the obtained light yellow powder in 500 Heat treatment at ℃ for 1.5h, and finally co-doped TiO 2 ;

[0078] co-doped TiO 2 Composite preparation with the supporting substrate: 0.4g co-doped TiO prepared above 2 and 1.2g of tin oxide nanowires were dispersed in N-methylpyrrolidone solution, stirred for 8h, then impregnated for 14h, dried at 90°C, and finally heat-treated at a temperature of 500°C with a flow rate of 200sccm n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com