Ultrasonic-Assisted Cavitation Abrasive Flow Finishing Method of Titanium Alloy Surface Oxide Layer

A surface oxidation and ultrasonic technology, which is applied in the field of ultrasonic-assisted cavitation abrasive flow finishing of the oxide layer on the surface of titanium alloy, can solve the problems of difficult control of the processing process, pollution of toxic gas and waste liquid, and easy over-corrosion, so as to avoid re-sticking Attachment, increase strength and randomness, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

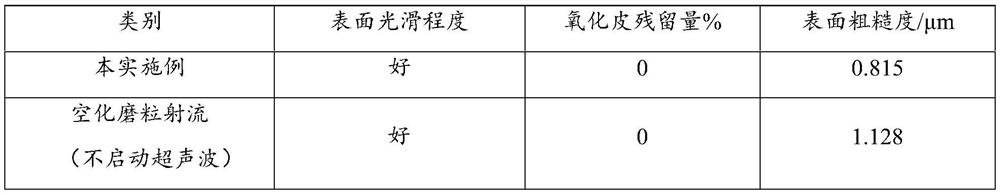

[0059] The processed workpiece is a TC4 titanium alloy rod with a length of 80mm and a diameter of 50mm, and the surface is covered with a 60-70μm thick low-temperature oxide layer.

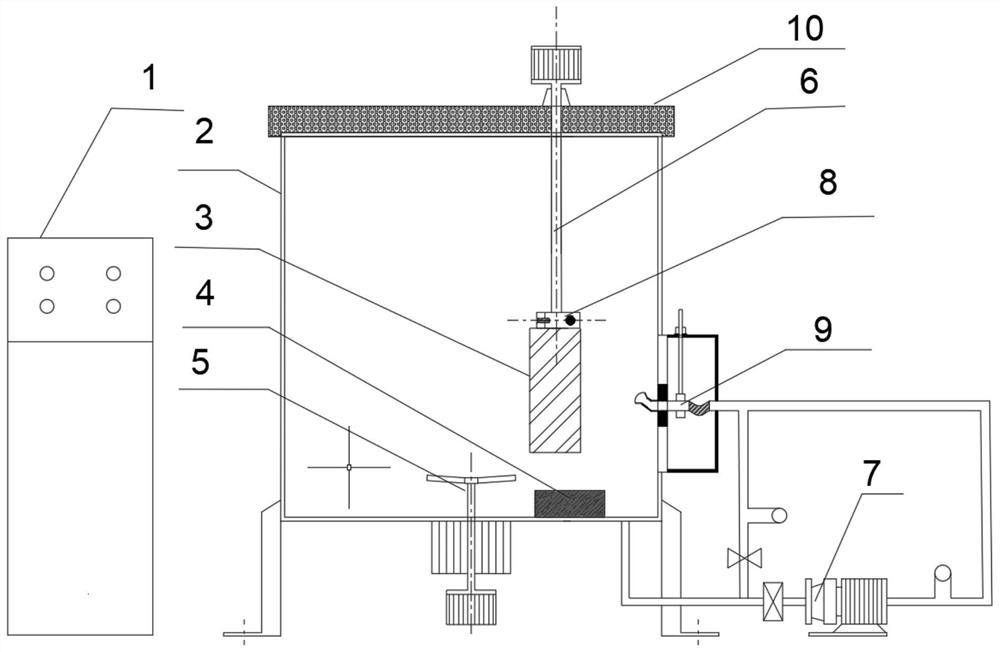

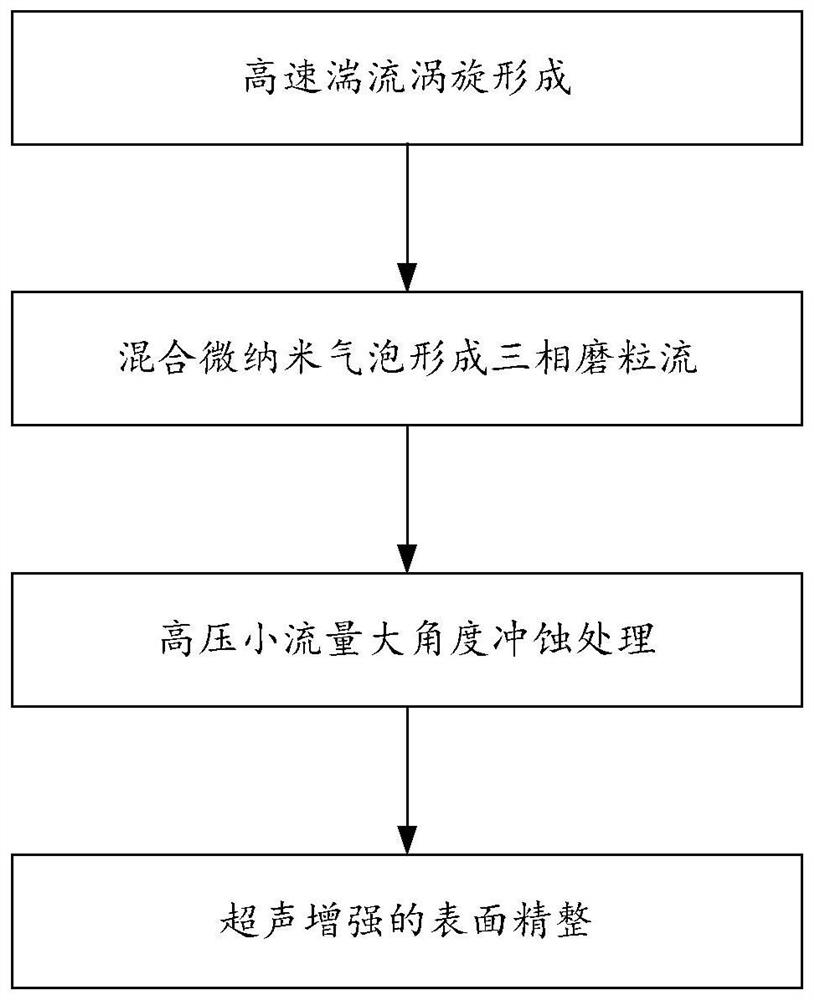

[0060] Step 1: forming a high-speed turbulent vortex, including: disposing a soft abrasive flow composed of pure water and 60# silicon carbide abrasive grains with a volume content of 20% in the working tank (2), and the liquid level is immersed in the workpiece. Start the turbulence generator (5) at the bottom center of the working tank (2) to make the solid-liquid two-phase fluid mix evenly and form a high-speed turbulent vortex;

[0061] Step 2: Forming a high-speed, high-pressure gas-liquid-solid three-phase fluid, including: starting the microbubble pump (7), and using the microbubble pump to extract a uniformly mixed solid-liquid two-phase flow to realize the generation of micronano bubbles and their fusion with the solid-liquid fluid , pressurization to form a high-speed high-pressure gas-...

Embodiment 2

[0068] The processed workpiece is a TC4 titanium alloy rod with a length of 80 mm and a diameter of 50 mm, and the surface is covered with a high-temperature oxide layer with a thickness of 600-700 μm.

[0069] Step 1: Forming a high-speed turbulent vortex, including: disposing soft water, 24# silicon carbide abrasive grains with a volume content of 15%, and 150# silicon carbide abrasive grains with a volume content of 15% in the working tank (2). Abrasive particle flow, the liquid level immerses the workpiece. The turbulence generator (5) at the bottom center of the working tank body (2) is activated to make the solid-liquid two-phase fluid mix uniformly and form a high-speed turbulent vortex.

[0070] Step 2: Forming a high-speed, high-pressure gas-liquid-solid three-phase fluid, including: starting the microbubble pump (7), and using the microbubble pump to extract a uniformly mixed solid-liquid two-phase flow to realize the generation of micronano bubbles and their fusion ...

Embodiment 3

[0076] The processed workpiece is a TC21 titanium alloy plate with length*width*thickness=120*120*3mm, covering a dense oxide layer with a thickness of 100μm to 150μm.

[0077]Step 1: forming a high-speed turbulent vortex, including: disposing soft water, 8% volume content of 150# silicon carbide abrasive grains, and 8 volume% volume content of 240# silicon carbide abrasive grains in the working tank (2). Abrasive particle flow, the liquid level immerses the workpiece. The turbulence generator (5) at the bottom center of the working tank body (2) is activated to make the solid-liquid two-phase fluid mix uniformly and form a high-speed turbulent vortex.

[0078] Step 2: Forming a high-speed, high-pressure gas-liquid-solid three-phase fluid, including: starting the microbubble pump (7), and using the microbubble pump to extract a uniformly mixed solid-liquid two-phase flow to realize the generation of micronano bubbles and their fusion with the solid-liquid fluid , pressurizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com