High-thermal-conductivity radiation crosslinked polyethylene pipe, and preparation method and application thereof

A radiation cross-linked polyethylene pipe technology is applied in the field of high thermal conductivity radiation cross-linked polyethylene pipes and their preparation, which can solve the problems of low hydraulic resistance, increased brittleness of pipes, easy occurrence of brittle cracks, etc. Wide service temperature, the effect of improving brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

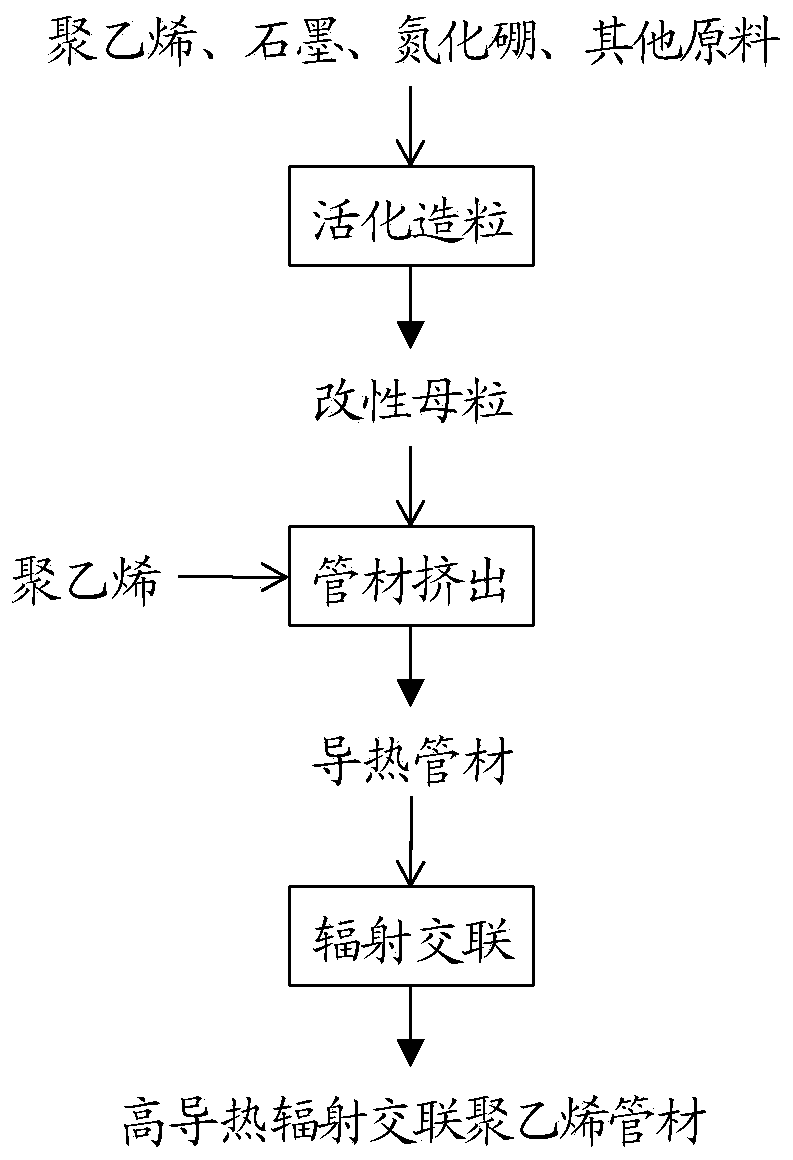

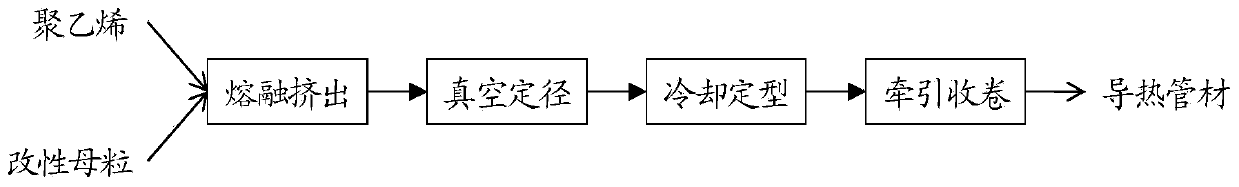

[0048] A high thermal conductivity radiation cross-linked polyethylene pipe is prepared by the following method (such as figure 1 shown):

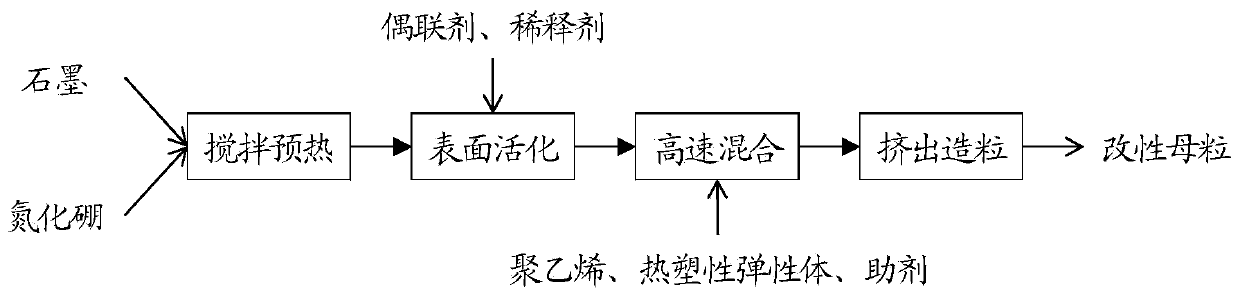

[0049] 1) Preparation of modified masterbatch (such as figure 2 shown):

[0050] Surface activation: first add 48 parts of 25 μm expandable graphite and 2 parts of 5 μm boron nitride into the high-speed mixer, and stir for 5 minutes at 60-70 ° C; then take 1.5 parts of silane coupling agent KH-550 through 3 parts of industrial white Add the oil to the powder after dilution, and continue to stir for 8 minutes;

[0051] Mixing and granulation: 50 parts of high-density polyethylene 5502, 15 parts of thermoplastic elastomer (10 parts of ethylene-vinyl acetate copolymer and 5 parts of ethylene-propylene copolymer), 2 parts of cross-linking sensitizer diethylene glycol Alcohol diacrylate and 0.5 part of antioxidant (0.3 part of 1010 and 0.2 part of 168) were added to the surface-activated powder, and stirred at high speed for 12 minutes. Th...

Embodiment 2

[0061] A high thermal conductivity radiation cross-linked polyethylene pipe is prepared by the following method:

[0062] 1) Preparation of modified masterbatch:

[0063] Surface activation: first add 16 parts of 45μm natural graphite and 4 parts of 20μm boron nitride into the high-speed mixer, stir at 55-65°C for 3 minutes; then take 1 part of titanate coupling agent TTS and wash it with 3 parts of absolute ethanol After dilution, add to the powder and continue to stir for 7 minutes;

[0064] Mixing and granulation: 20 parts of medium density polyethylene DX800, 5 parts of thermoplastic elastomer (2 parts of ethylene-vinyl acetate copolymer and 3 parts of ethylene-octene copolymer), 2.5 parts of cross-linking sensitizer trimethylol Propane trimethacrylate and 0.5 part of antioxidant (0.3 part of 1010 and 0.2 part of 1178) were added to the surface-activated powder, and stirred at high speed for 10 minutes. The rest are the same as embodiment 1.

[0065] 2) Extrusion of hea...

Embodiment 3

[0070] A high thermal conductivity radiation cross-linked polyethylene pipe is prepared by the following method:

[0071] 1) Preparation of modified masterbatch:

[0072] Surface activation: first add 100 parts of 15 μm colloidal graphite and 25 parts of 2 μm boron nitride into a high-speed mixer, and stir for 5 minutes at 70-80°C; then take 5 parts of aluminum-titanium composite coupling agent HY-133 and pass through 10 parts of industrial Add white oil to the powder after dilution, and continue to stir for 10 minutes;

[0073] Mixing and granulation: 40 parts of medium density polyethylene SP980, 45 parts of thermoplastic elastomer (35 parts of ethylene-vinyl acetate copolymer and 10 parts of ethylene-butylene copolymer), 3 parts of cross-linking sensitizer trimethylol Propane triacrylate and 1 part of antioxidant (0.7 part of 754 and 0.3 part of 168) were added to the surface-activated powder, and stirred at high speed for 15 minutes. The rest are the same as embodiment 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com