Epoxy modified polyurethane waterproof coating and preparation method thereof

A technology of polyurethane waterproofing and epoxy modification, applied in the field of coatings, can solve problems such as unsatisfactory thixotropic effect, poor construction, and increased viscosity, and achieve the effects of improving anti-sag performance, anti-settling, and increasing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

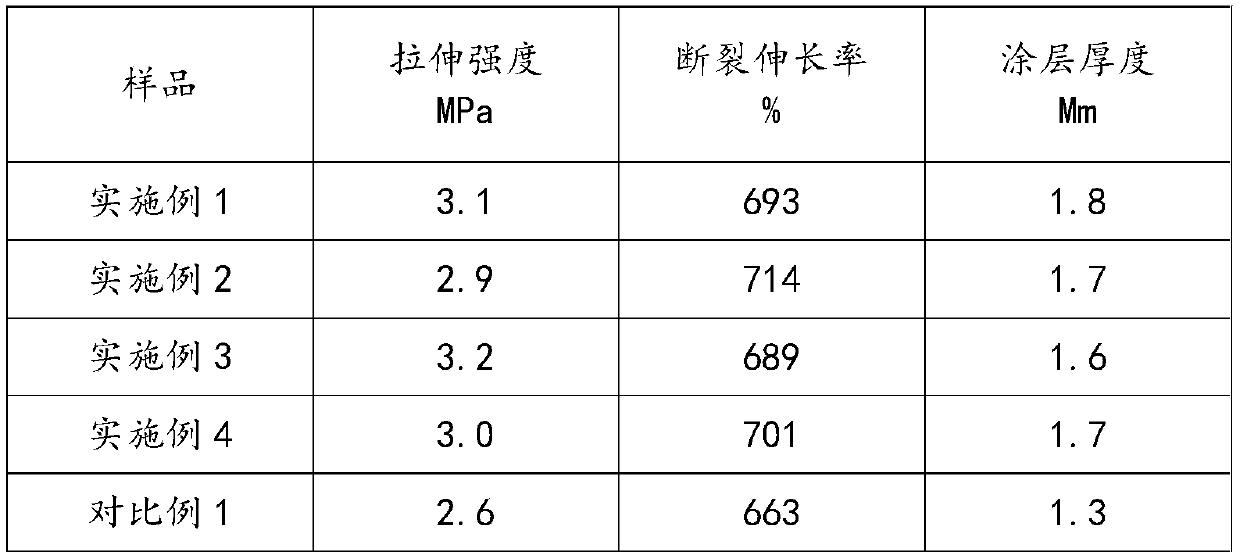

Examples

Embodiment 1

[0024] This embodiment provides a kind of epoxy resin modified polyurethane waterproof coating, and described coating comprises the composition of following parts by weight, epoxy modified polyether polyol 40 parts, isophorone diisocyanate 10 parts, bicyclic 8 parts of hexylmethane diisocyanate, 13 parts of glycerol triacetate, 40 parts of modified nano-silica, 3 parts of 2-isopropyl oxazolidine, 1 part of dibutyltin dilaurate, polyether modified organic 0.3 parts of silicon defoamer, 3 parts of modified fumed silica;

[0025] The preparation method of the epoxy-modified polyurethane waterproof coating mainly comprises the steps:

[0026] (1) In a closed reactor with high-speed stirring, add 400 g of epoxy-modified polyether polyols, 130 g of glycerol triacetate, and 400 g of modified nano-silicon dioxide in sequence, stir rapidly and raise the temperature to 100 -105°C, turn on the vacuum pump and pump for 2-3 hours below -0.08MPa to completely remove the moisture in the sys...

Embodiment 2

[0030] The present embodiment provides a kind of epoxy resin modified polyurethane waterproof coating, described coating comprises the composition of following parts by weight, epoxy modified polyether polyol 35 parts, isophorone diisocyanate 8 parts, hexaethylene 10 parts of methyl diisocyanate, 15 parts of glycerol triacetate, 35 parts of modified nano-silica, 2 parts of 2,2-dihydrooxazolidine, 1 part of dibutyltin acetate, polyether modified silicone 0.3 parts of foaming agent, 4 parts of modified fumed silica;

[0031] The preparation method of described waterproof paint is with embodiment 1.

Embodiment 3

[0033] This embodiment provides a kind of epoxy resin modified polyurethane waterproof coating, the coating comprises the composition of following parts by weight, epoxy modified polyether polyol 45 parts, xylylene diisocyanate 7 parts, six 8 parts of methylene diisocyanate, 15 parts of chlorinated paraffin, 45 parts of modified nano-alumina, 2 parts of 2,2-dihydrooxazolidine, 1 part of dibutyltin dilaurate, polyether modified silicone 0.3 parts of foaming agent, 1 part of modified fumed silica;

[0034] The preparation method of described waterproof paint is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com