Reducing carbon nitride photocatalyst, preparation method and application thereof

A photocatalyst and catalyst technology, applied in the field of photocatalysis, can solve the problems of shifting up the valence band and shifting down the conduction band, etc., to achieve the effects of reducing the bandgap width, improving the oxidation ability, and improving the separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Weigh 5g of melamine in an alumina crucible and heat it in a muffle furnace at 5°C min -1 The heating rate is heated to 550 ° C for 4 hours. After it has cooled to room temperature, g-C is obtained by grinding and sieving 3 N 4 powder;

[0037] 2. Add NaBH with a mass ratio of 0.05:1 4 and g-C 3 N 4 The powder is mixed well in a mortar.

[0038] 3. Put the well-mixed sample into the tube furnace, under N 2 At 5°C·min under atmosphere -1 The temperature was raised to 600°C for 30 minutes at a certain rate.

[0039] 4. After cooling in an open atmosphere, the product was rinsed 5 times with deionized water and ethanol, and dried at 70 °C for 24 h to obtain a reducing carbon nitride (RCN) photocatalyst powder.

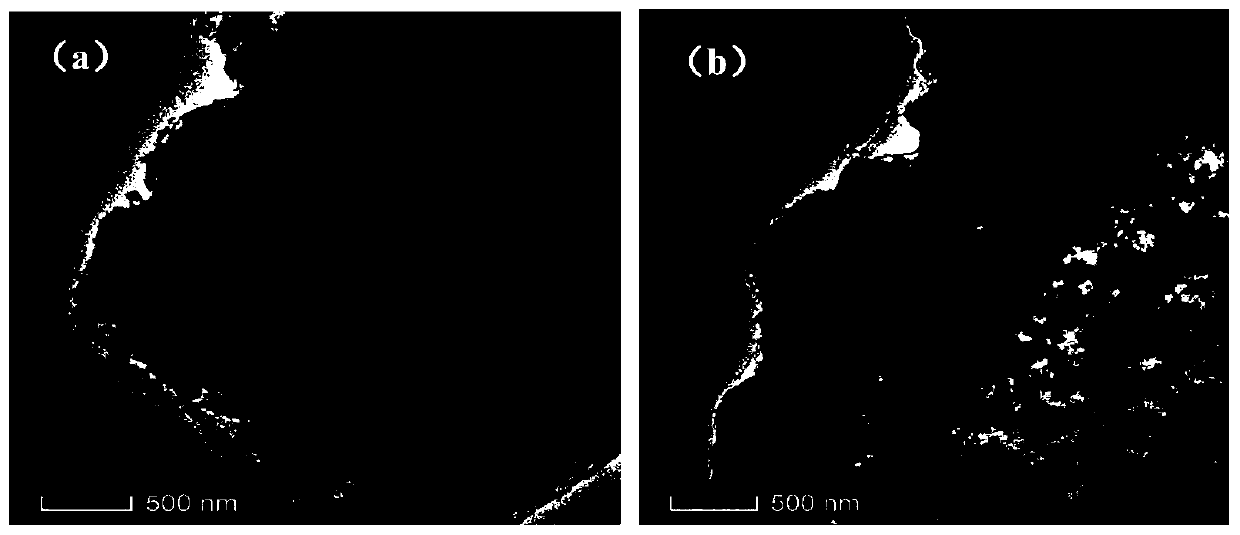

[0040] figure 1 Be the reducing carbon nitride (RCN) in the present embodiment and the g-C in the comparative example 1 3 N 4 Transmission electron microscope (TEM) image of . Among them, (a) is g-C 3 N 4 , (b) is RCN. from figure 1 RCN and g-C ...

Embodiment 2

[0053] 1. Weigh 5g of melamine in an alumina crucible and heat it in a muffle furnace at 5°C min -1 The heating rate is heated to 520 ° C for 5 hours. After it has cooled to room temperature, g-C is obtained by grinding and sieving 3 N 4 powder.

[0054] 2. Add NaBH with a mass ratio of 0.11:1 4 and g-C 3 N 4 Put in a mortar and mix well, put the well mixed sample into a tube furnace, under N 2 At 6°C·min under atmosphere -1 The temperature was raised to 570°C for 40 minutes at a certain rate.

[0055] 3. After cooling in an open atmosphere, the product was rinsed 4 times with deionized water and ethanol, and dried at 75°C for 22 h to obtain a reducing carbon nitride (RCN) photocatalyst powder.

Embodiment 3

[0057] 1. Weigh 5g of melamine in an alumina crucible and heat it in a muffle furnace at 5°C min -1 The heating rate is heated to 530 ° C for 4.5 hours. After it has cooled to room temperature, g-C is obtained by grinding and sieving 3 N 4 powder.

[0058] 2. Add NaBH with a mass ratio of 0.08:1 4 and g-C 3 N 4 Mix thoroughly in a mortar, put the fully mixed sample into a tube furnace, and heat at 6°C min under an argon atmosphere. -1 The temperature was raised to 580°C for 35 minutes at a certain rate.

[0059] 3. After cooling in an open atmosphere, the product was rinsed three times with deionized water and ethanol, and dried at 65 °C for 20 h to obtain a reducing carbon nitride (RCN) photocatalyst powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com