Oyster and silkworm pupa solid beverage and preparation method thereof

A technology of solid beverage and silkworm chrysalis, which is applied in the field of beverage processing, can solve the problems of difficulty in preserving nutritional value, incapable of absorbing kidney and calming Chong, and inability to relieve pain, etc. It can achieve stable quality, safe and non-toxic consumption, and promote skin metabolism. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

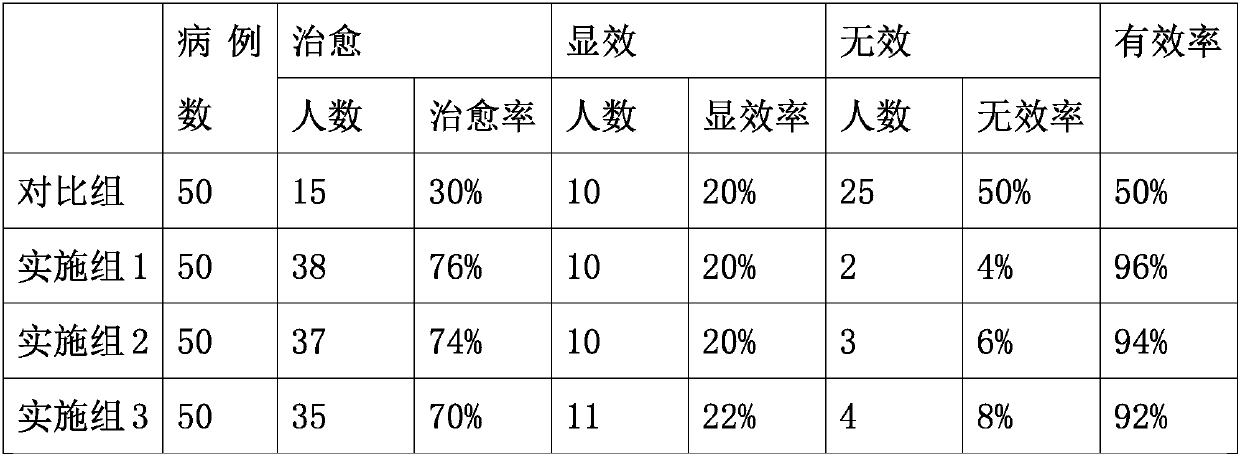

Examples

preparation example Construction

[0022] A preparation method of oyster silkworm chrysalis solid beverage, comprising the steps of:

[0023] a. Weigh the corresponding raw materials according to the above weight;

[0024] b. Fully clean the raw materials, then send them into the grinding and crushing equipment, carry out sufficient grinding and grinding, and fully filter them, and use 800-mesh sieve to filter the powder;

[0025] c. Add the mixed sugar, then rotate and mix at high speed, and carry out secondary crushing, and then sieve;

[0026] d. Dry the mixed powder, and then send it into a granulator for granulation.

[0027] e. Raw material packaging: The prepared granules are packed into packaging bags according to a fixed weight. After the loading is completed, the whole is sealed to complete the production.

[0028] Wherein, in step b, the raw materials can also be boiled and extracted, then concentrated, and finally spray-dried into powder.

Embodiment 1

[0030] a. In parts by weight, weigh 7 parts of oyster, 9 parts of silkworm chrysalis, 5 parts of sea cucumber, 3 parts of almond, 5 parts of ginseng, 2 parts of medlar, 4 parts of mulberry, 5 parts of raspberry, 5 parts of cinnamon, 3 parts of black sesame, 6 parts of black beans, 3 parts of tangerine peel, 1.5 parts of yam, 3.8 parts of Gorgon fruit, 4 parts of longan meat, 8 parts of almond, 10 parts of Yizhi kernel, 7 parts of Cordyceps militaris;

[0031] b. Fully clean the raw materials, then send them into the grinding and crushing equipment, carry out sufficient grinding and grinding, and fully filter them, and use 800-mesh sieve to filter the powder;

[0032] c. Add 0.1 part of okra powder, 0.5 part of eucommia seed oil microcapsule powder and 0.2 part of walnut powder, then rotate and mix at high speed, and carry out secondary crushing to it, and then sieve;

[0033] d. Dry the mixed powder, and then send it into a granulator for granulation.

[0034] e. Raw material...

Embodiment 2

[0037] a. In terms of parts by weight, weigh 3 parts of oysters, 4 parts of silkworm chrysalis, 2 parts of sea cucumber, 1.5 parts of almond, 2.5 parts of ginseng, 1 part of medlar, 2 parts of mulberry, 2.5 parts of raspberry, 2 parts of cinnamon, 1 part of black sesame, 3.5 parts of black beans, 1.5 parts of tangerine peel, 0.5 parts of yam, 1.7 parts of Gorgon fruit, 2 parts of longan meat, 4 parts of almonds, 5 parts of Yizhi kernels, 4 parts of Cordyceps militaris;

[0038] b. Fully clean the raw materials, then send them into the grinding and crushing equipment, carry out sufficient grinding and grinding, and fully filter them, and use 800-mesh sieve to filter the powder;

[0039] c. Add 0.1 part of honey, 0.1 part of rock sugar and 0.1 part of fructooligosaccharide, then rotate and mix at high speed, and carry out secondary crushing, and then sieve;

[0040] d. Dry the mixed powder, and then send it into a granulator for granulation.

[0041] e. Raw material packaging: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com