Iron-modified biochar particle as well as preparation method and application thereof

A biochar and particle technology, applied in chemical instruments and methods, water pollutants, adsorbed water/sewage treatment, etc., can solve the problems of low efficiency of hexavalent chromium, and achieve low production cost, good removal effect, and simple synthesis. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

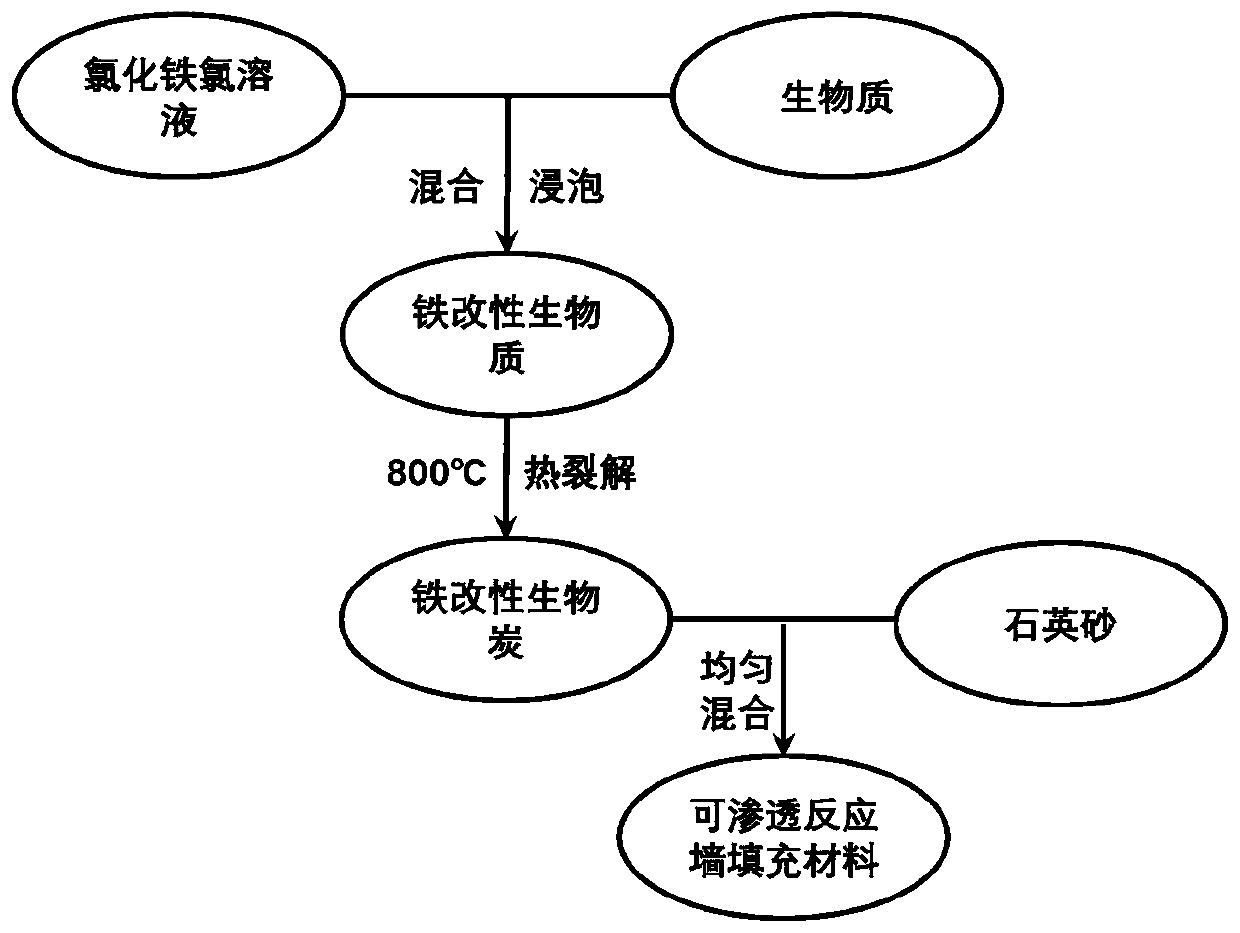

[0032] Such as figure 2 As shown, the invention provides a kind of preparation method of iron-modified biochar particles, comprising the following steps:

[0033] Put the biomass material at a concentration of 0.5mol L -1 After soaking in the soluble iron salt solution for 1.5-3 days, take out the soaked biomass material, dry it at 45-80°C, and crack it at 700-900°C for 2 hours;

[0034] Wherein the mass ratio of the iron element in the biomass to the soluble iron salt is (3-7):1, preferably 5:1.

[0035] The invention prepares the iron-modified biochar particles with a specific surface area of 400-700m 2 g -1 .

[0036]The soluble iron salt is one or a mixture of ferric chloride, ferrous sulfate or ferric nitrate.

[0037] The biomass material is tree plant, preferably poplar and / or willow.

[0038] An iron-modified biochar particle prepared by the method is characterized in that, the particle size is 0.5-2mm, and the iron-modified biochar is doped with Fe 0 , Fe 2...

Embodiment 1

[0042] Such as figure 2 As shown, the embodiment of the present invention provides a method for preparing iron-modified biochar particles, comprising the following steps:

[0043] Step S11, prepare ferric chloride solution: weigh a certain amount of ferric chloride solid and dissolve it in ultrapure water, add a small amount of hydrochloric acid to prevent the precipitation of ferric iron, stir it with a glass rod until it is completely dissolved, then put it into a volumetric flask to constant volume , dubbed molar concentration of 0.5mol L -1 ferric chloride solution;

[0044] Step S12, preparing biomass: After crushing the biomass poplar, select particles with a particle size of 0.5-2mm, and dry them at 60°C.

[0045] Step S13, preparing iron-modified biomass: the above 0.5mol L -1 Mix and soak the ferric chloride solution and biomass according to the mass ratio of biomass and iron 5:1. During the soaking process, stir with a glass rod to make the biomass fully absorb t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com