Method for improving quality of piezoelectric ceramic buzzing piece

A piezoelectric ceramic sheet and piezoelectric ceramic technology, which is applied to instruments, sound-producing instruments, etc., can solve the problems of poor coating quality of silver electrodes, poor density consistency, and low polarization pass rate, etc., to overcome the problems of low density and geometric size. Good, uniform effect of polarization treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

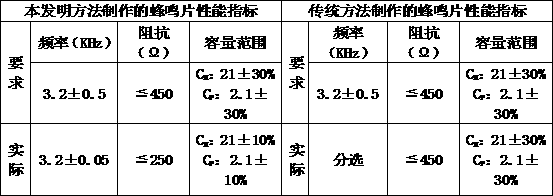

[0027] Example 1, prepare the specifications of the buzzer sheet: the size of the metal sheet is Φ27mm×0.18mm, the specification of the piezoelectric ceramic sheet is Φ20mm×0.15mm, and the frequency of the buzzer sheet after the two are bonded is required to be 3.2KHz±0.5KHz.

[0028] 1) Prepare piezoelectric ceramic powder according to the conventional method:

[0029] 1.1) Primary ball milling: Pb 3 o 4 , ZrO 2 、TiO 2 , Sb 2 o 3 , Nb 2 o 5 , NiO, MgO, Li 2 CO 3 The raw material powder is mixed according to the conventional method, and then mixed with absolute ethanol and zirconium balls according to the conventional method, ball milled, dried and sieved according to the conventional method to obtain green porcelain powder;

[0030] 1.2) Pre-firing: sinter the raw porcelain powder according to the conventional method, and sieve after cooling to obtain porcelain powder;

[0031] 1.3) Secondary ball milling: the porcelain powder is mixed with absolute ethanol and zirc...

Embodiment 2

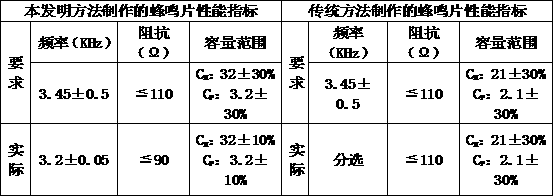

[0044] Example 2, the specifications of the buzzer sheet are prepared: the size of the metal sheet is Φ34.7mm×0.30mm, the specification of the piezoelectric ceramic sheet is Φ25mm×0.246mm, and the frequency of the buzzer sheet after the two are bonded is required to be 3.45KHz±0.5KHz.

[0045] Each step is with embodiment 1. Among them, the weight ratio of the piezoelectric ceramic powder to the polyvinyl alcohol colloid in step 2) is 100:6; the aggregate particle size in step 3) is 8 μm; the outer dimension of the green bar in step 4) is Φ29 .0mm×130mm, isostatic pressure 300Mpa; in step 6), the outer diameter of the piezoelectric ceramic rod is Φ25mm, and the thickness of the piezoelectric ceramic sheet is 0.30mm.

[0046] Randomly select 50 buzzer chips prepared in this example and 50 buzzer chips prepared by traditional technology, and test the resonant frequency, resonant impedance, capacity range and other properties. Table 2 of the test data.

[0047] Table 2: Comparis...

Embodiment 3

[0049] Example 3, prepare the buzzer sheet in Example 1.

[0050] Each step is with embodiment 1. Wherein, the weight ratio of the piezoelectric ceramic powder to the polyvinyl alcohol colloid in step 2) is 100:3; the aggregate particle size in step 3) is 5 μm; the isostatic pressure in step 4) is 200Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com