Preparation method of methyl methacrylate

A technology of methyl methacrylate and methacrolein, which is applied in the field of catalytic synthesis, can solve the problems of catalyst activity decline, catalyst collision wear, energy consumption and environment, etc., and achieve the goal of improving stability, improving environmental protection index and prolonging service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

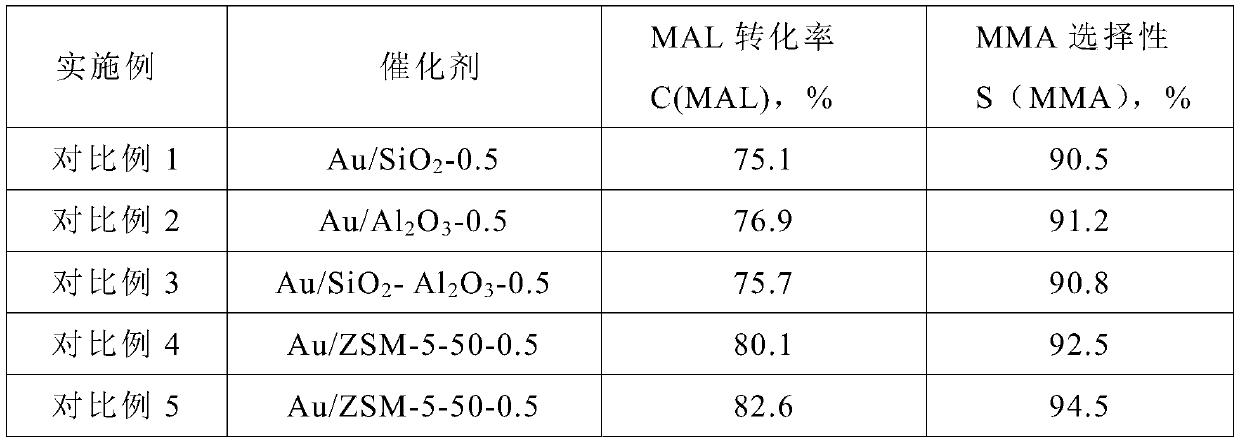

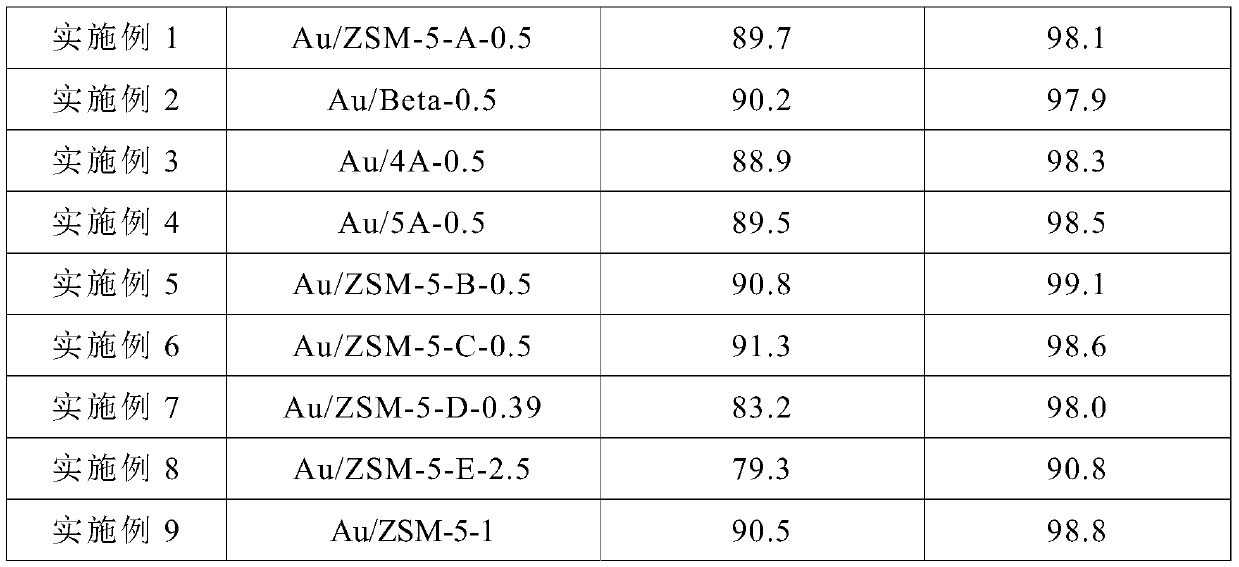

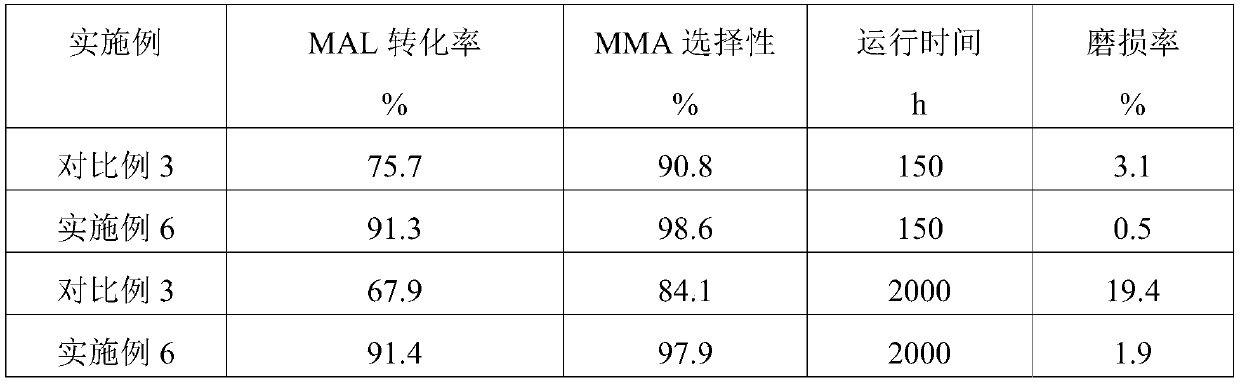

Examples

Embodiment 1

[0046] The preparation method of the catalyst is the same as that of Comparative Example 1, except that the silica is replaced with Na-ZSM-5 molecular sieve powder of the same mass and the ratio of silicon to aluminum is 100, and the resultant is dried at 100 °C; the dried product is calcined at 450 °C for 5h , and then placed in a reduction furnace, the heating rate was 10-15 °C / min, and hydrogen was introduced for reduction, and the hydrogen flow rate was maintained at 30 ml / min. After reduction for 1 h, the catalyst Au / ZSM-5-A was obtained, in which the gold loading was 0.5%. wt. The attrition rate of the catalyst measured according to the American ASTM D5757-00 standard was 0.7%.

Embodiment 2

[0048] The preparation method of the catalyst is the same as that of Comparative Example 1, except that the silica is replaced with Na-Bate molecular sieve powder of the same mass and the ratio of silicon to aluminum is 100, and the resultant is dried at 100 °C; Put it in a reduction furnace with a heating rate of 10-15°C / min, and introduce hydrogen for reduction. The hydrogen flow rate is kept at 30ml / min. After reduction for 1h, the catalyst Au / Beta is obtained, and the gold loading is 0.5%wt. The wear rate of the catalyst measured according to the American ASTM D5757-00 standard was 0.9%.

Embodiment 3

[0050] The preparation method of the catalyst is the same as that of Comparative Example 1, except that the silica is replaced with Na-4A molecular sieve powder of the same mass and the ratio of silicon to aluminum is 100, and the resultant is dried at 100 °C; Placed in a reduction furnace, heating at a rate of 10-15°C / min, introducing hydrogen for reduction, maintaining a hydrogen flow rate of 30ml / min, and reducing the catalyst for 1 hour to obtain catalyst Au / 4A with a gold loading of 0.5%wt. The wear rate of the catalyst measured according to the American ASTM D5757-00 standard was 0.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com