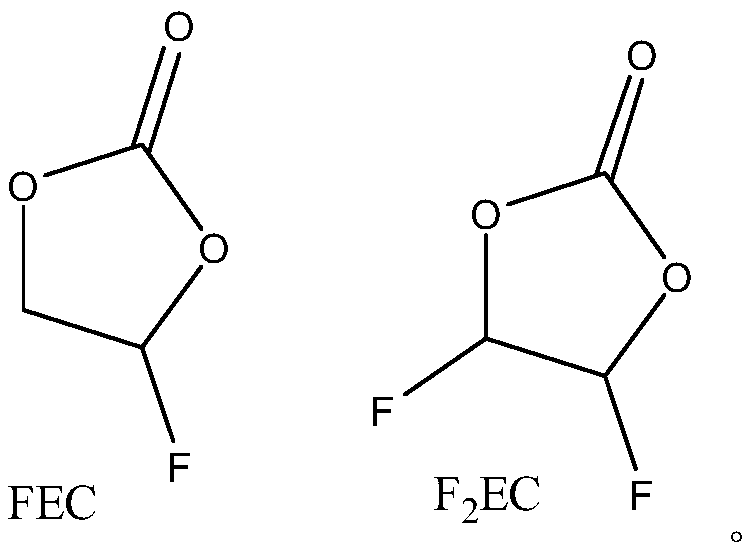

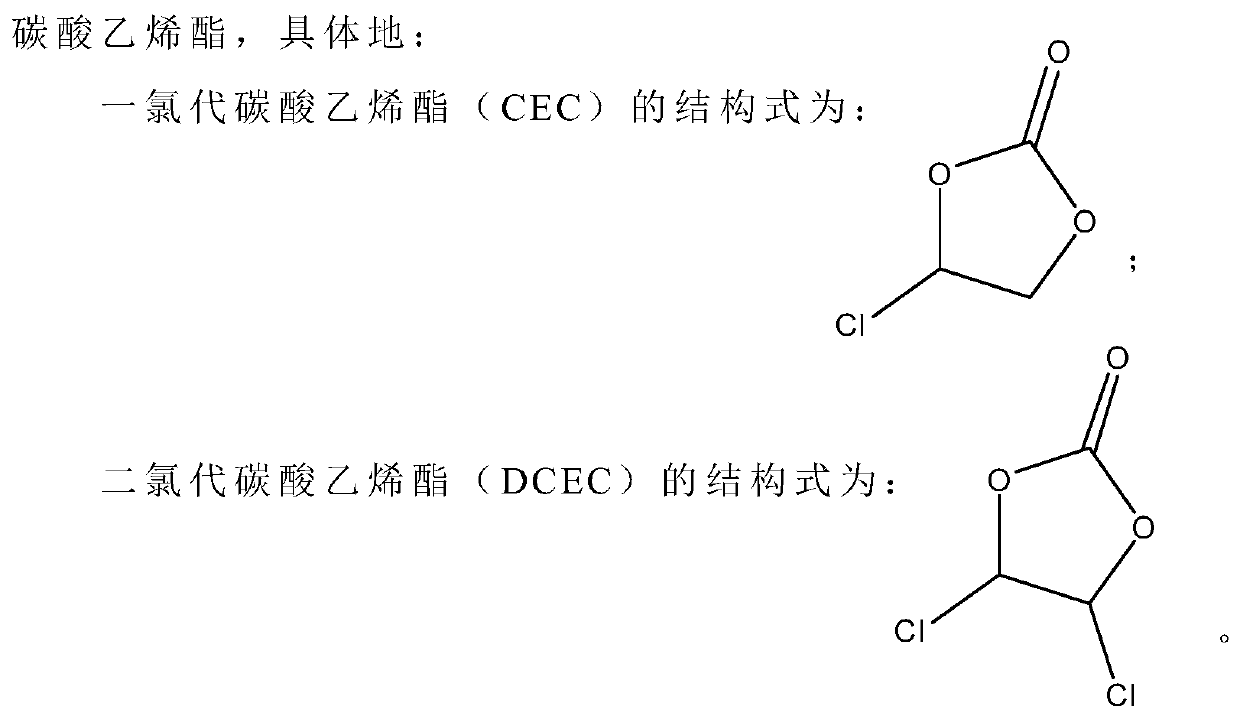

Preparation method and application of fluoroethylene carbonate

A technology of fluoroethylene carbonate and chloroethylene carbonate, which is applied in the field of organic synthesis, can solve problems such as difficult separation, long reaction time, and performance degradation of lithium batteries, and achieve mild reaction conditions, short reaction time, and good safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Under nitrogen protection, add 80 g of anhydrous sodium bifluoride, 0.4 g of tetraphenylphosphine bromide (TPPB), 200 ml of ethyl acetate into the reaction vessel, stir and raise the temperature to 70 ° C, and dropwise add 250 g of chloroethylene carbonate (CEC) ( The purity is 82.5%, purchased from Zhangjiagang Bairuisi), dripping in 1 hour, 77 ° C for 2 hours, cooled to 40 ° C for suction filtration, the filter residue was rinsed twice with 100 ml ethyl acetate, and the combined filtrate was decompressed to remove the solvent to obtain a Fluoroethylene carbonate crude product 168g, GC content 80.5%, yield 94.4%.

Embodiment 2

[0032] Under the protection of nitrogen, add 90 g of anhydrous potassium hydrogen fluoride, 0.6 g of tetrakis(diethylamine) phosphonium bromide (TPB), 200 ml of dimethyl carbonate into the reaction vessel, stir and raise the temperature to 80°C, and start adding monochloroethylene carbonate dropwise Ester (CEC) 250g (purity: 82.5%), dripped in 1 hour, kept at 90°C for 2 hours, cooled to 40°C for suction filtration, rinsed the filter residue twice with 100ml ethyl acetate, combined the filtrate to remove the solvent under reduced pressure to obtain monofluoro The crude ethylene carbonate was 173g, the GC content was 78.52%, and the yield was 97.1%.

Embodiment 3

[0034] Under nitrogen protection, 112 g of anhydrous potassium hydrogen fluoride, 0.9 g of tetrakis(diethylamine) phosphonium bromide (TPB), 250 ml of methyl tert-butyl ether were added to the reaction vessel, and the temperature was raised to 55°C with stirring to start adding dichloride Ethylene carbonate (DCEC) 200g (purity: 97.2%, Zhangjiagang Bairuisi), dripped in 2 hours, kept at 60°C for 2 hours, cooled to 40°C for suction filtration, rinsed the filter residue twice with 100ml ethyl acetate, combined the filtrates and reduced pressure The solvent was removed to obtain 148g of crude difluoroethylene carbonate, the GC content was 84.5%, and the yield was 96.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com