A kind of low freezing point wetting type dust suppressant and preparation method thereof

A technology of dust suppressant and freezing point, which is applied in the field of low freezing point wetting dust suppressant and its preparation, can solve problems such as relatively large impact, and achieve the effects of reducing water loss, long-term moisturizing performance, and enhancing wetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

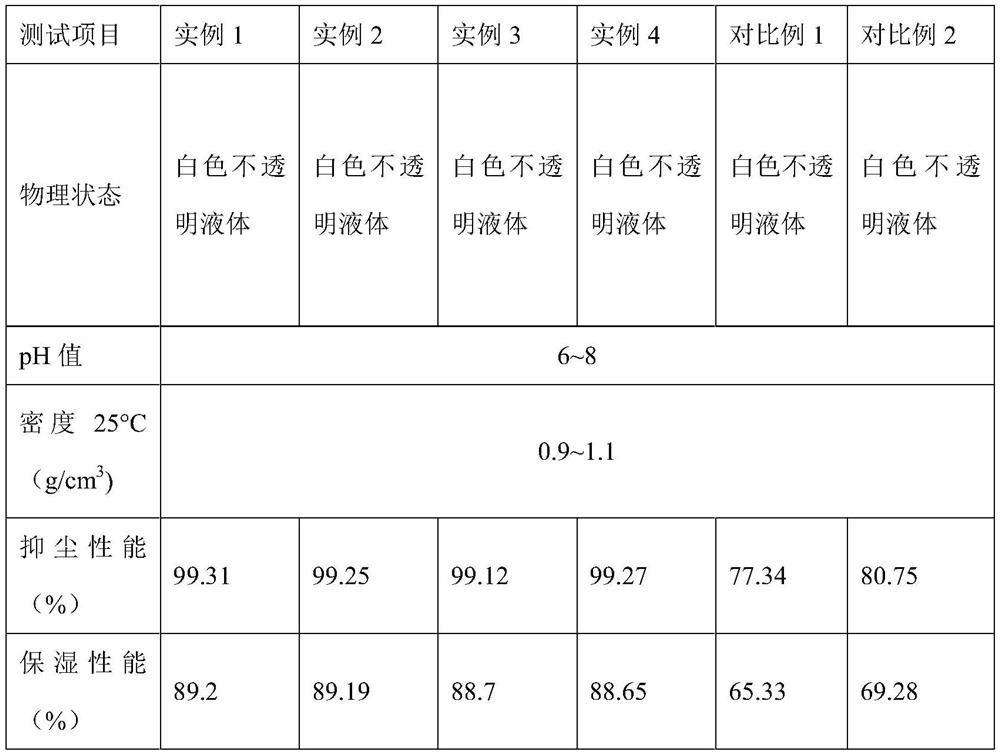

Examples

Embodiment 1

[0040] The present embodiment provides a low freezing point wetting type dust suppressant, which is composed of the following components in parts by mass:

[0041] Sodium lactate: 0.3%, Polypropylene alcohol: 0.9%, Epoxy resin: 0.2%, Glycerin: 5%, Methylcellulose: 1%, Sodium dodecylbenzenesulfonate: 0.4%, Styrene acrylic emulsion: 0.3% , water: 91.9%.

[0042] The preparation method of the dust suppressant of the present embodiment comprises the following steps:

[0043] (1) The water is divided into two parts A and B, A541g, B378g, A is heated to 60°C, B is heated to 40°C;

[0044] (2) 4g of sodium dodecylbenzenesulfonate, 9g of polypropylene alcohol, 10g of methyl cellulose, and 2g of epoxy resin were stirred uniformly, then added water in part A, and cooled to room temperature after stirring for 30min at a rotating speed of 100rpm / min, to obtain aqueous solution a;

[0045] (3) adding sodium lactate 3g, glycerol 50g, styrene-acrylic emulsion 3g to water in part B, after ...

Embodiment 2

[0059] The present embodiment provides a low freezing point wetting type dust suppressant, which is composed of the following components in parts by mass:

[0060] Sodium lactate: 0.5%, polyacryl alcohol: 1%, epoxy resin: 0.4%, glycerin: 8%, xanthan gum: 1%, polyacrylamide: 0.5%, fatty alcohol polyoxyethylene glycol ether: 0.4%, pure Acrylic emulsion: 0.3%, water: 87.9%.

[0061] The preparation method of the dust suppressant of the present embodiment comprises the following steps:

[0062] (1) The water is divided into two parts A and B, A475g, B378g, A is heated to 65°C, B is heated to 45°C;

[0063] (2) Stir 4 g of fatty alcohol polyoxyethylene glycol ether, 10 g of polyacryl alcohol, 10 g of xanthan gum, 5 g of polyacrylamide, and 4 g of epoxy resin, then add water in part A, and cool after stirring for 25 minutes at 150 rpm / min. to room temperature to obtain aqueous solution a;

[0064] (3) adding sodium lactate 5g, glycerol 80g, pure acrylic emulsion 3g to water in pa...

Embodiment 3

[0068] The present embodiment provides a low freezing point wetting type dust suppressant, which is composed of the following components in parts by mass:

[0069] Sodium lactate: 0.3%, polyacryl alcohol: 0.9%, epoxy resin: 0.2%, glycerin: 0.5%, hydroxymethyl cellulose: 1%, sodium dodecylbenzene sulfonate: 0.4%, styrene-acrylic emulsion: 0.3 %, water: 96.4%.

[0070] The preparation method of the dust suppressant of the present embodiment comprises the following steps:

[0071] (1) The water is divided into two parts A and B, A:B is 1:1, A482g, B 482g, A is heated to 70 ℃, B is heated to 50 ℃;

[0072] (2) Stir 4g of sodium dodecylbenzenesulfonate, 9g of polyacryl alcohol, 10g of xanthan gum, 10g of binder, and 2g of epoxy resin, then add part A of water, and stir for 20min at a rotating speed of 200rpm / min Cool to room temperature to obtain aqueous solution a;

[0073] (3) adding sodium lactate 3g, glycerol 5g, pure acrylic emulsion 3g to water in part B, and after stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com