A kind of corrosion-resistant bearing steel and its ion implantation surface treatment method

An ion implantation and surface treatment technology, applied in ion implantation plating, vacuum evaporation plating, coating and other directions, can solve the problem of improving the surface corrosion resistance and difficult to meet the strict requirements of bearing steel, and achieve the reduction of Young's modulus. , The effect of improving corrosion resistance and brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

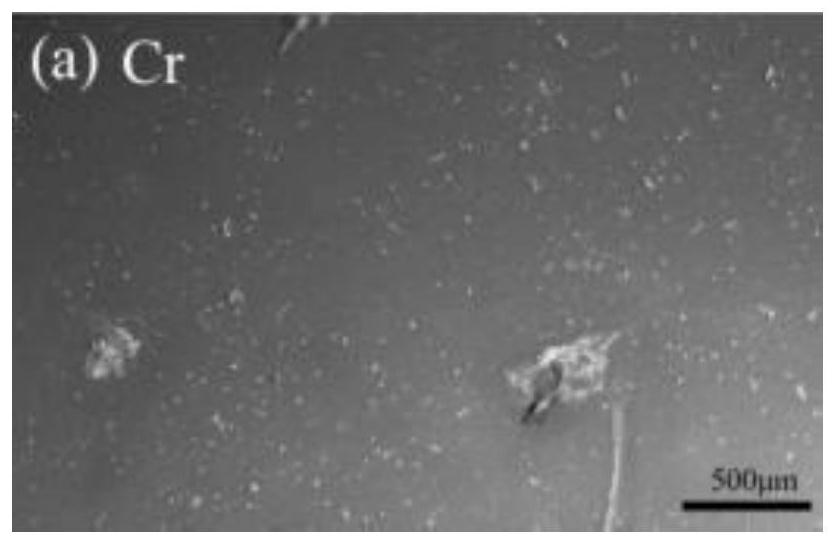

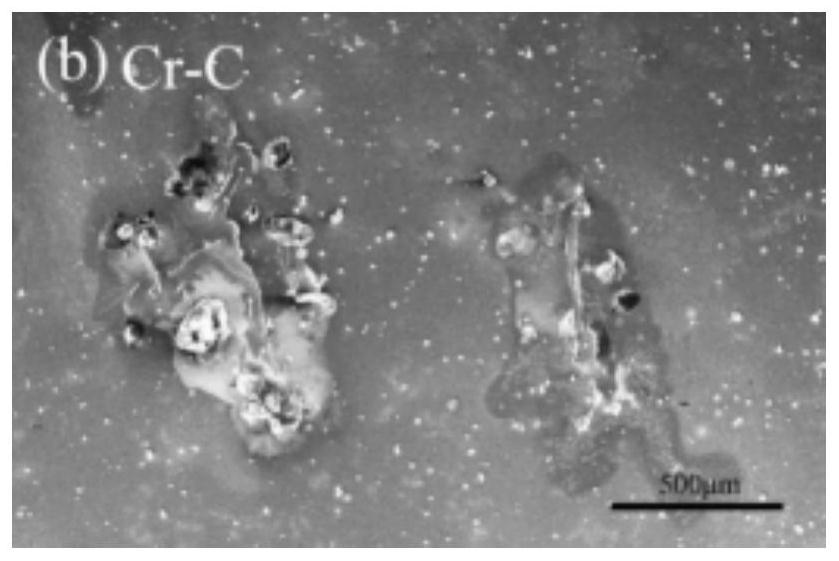

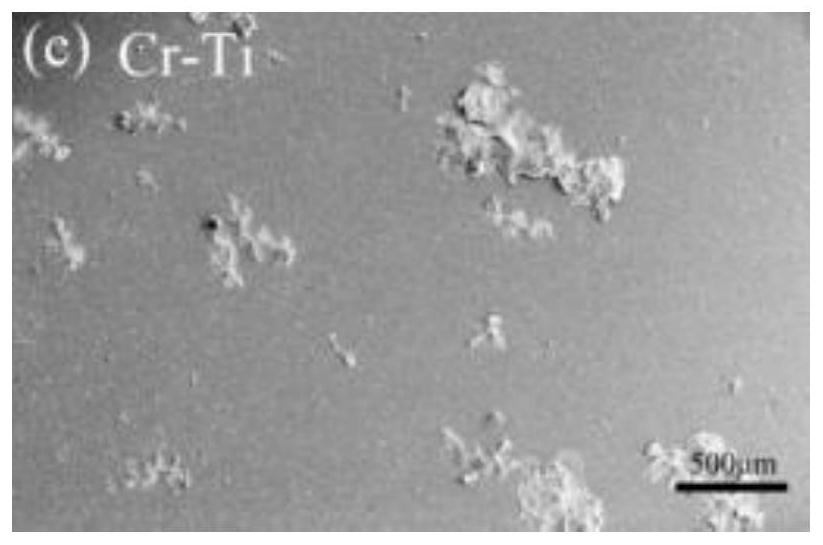

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0025] The CSS-42L sample composition that the present embodiment adopts is

[0026]

[0027] Material preparation: Cut 10×10×5mm from hardened CSS-42L steel ingot 3 The sample was mechanically polished to 3000# with SiC emery paper, and then polished to a mirror surface with a diamond polishing agent with a particle size of 1.5 μm, cleaned and dried.

[0028] Cr film preparation and ion implantation: The samples were ultrasonically cleaned with acetone before the chromium film was prepared. The high-purity chromium target is used as the cathode. Before deposition, the surface cleaning and Cr ion implantation are carried out with the Cr ion beam drawn from the magnetic filter cathode arc vacuum system. The implantation conditions are: 8kV voltage, 4mA beam current, and charge injection The amount is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com