Continuous production method of DL-homocysteine thiolactone hydrochloride

A technology of cystine thiolactone and cystine hydrochloride, which is applied in the field of continuous production technology, can solve the problems of not meeting medical standards, heavy metal pollution of lead electrodes, etc., so as to solve the problem of heavy metal pollution, no heavy metal pollution, and improve product quality. Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

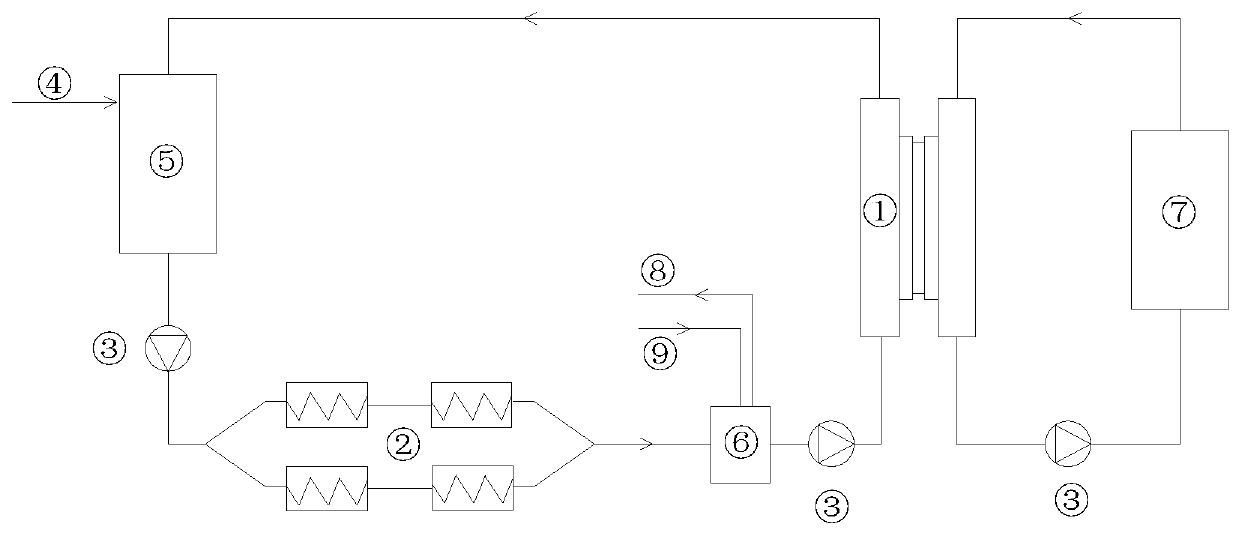

[0045] Reactor see figure 1 , using 7 microchannel reactors connected in parallel and then connected to the plate-and-frame electrolyzer.

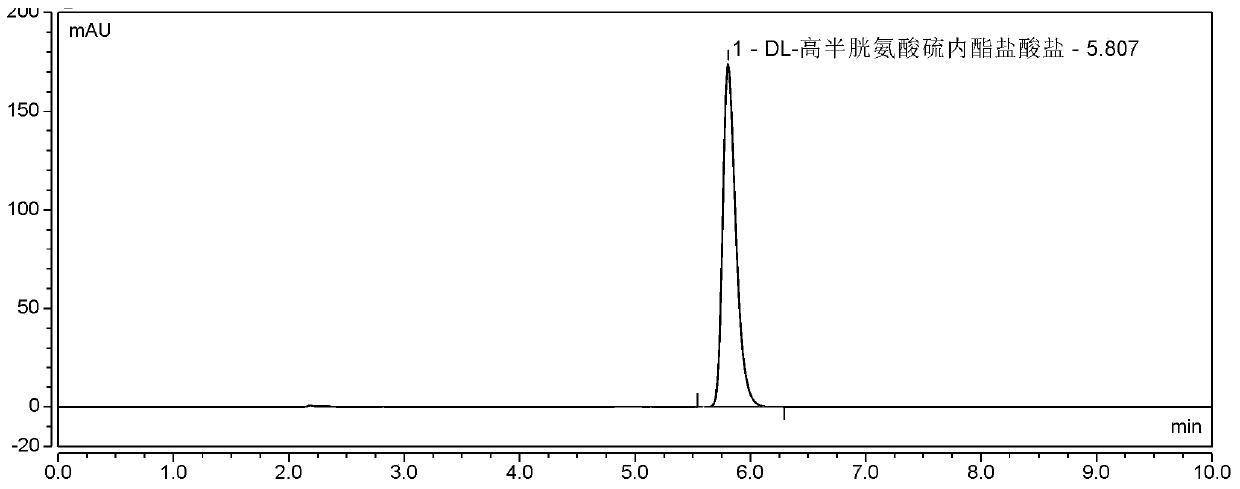

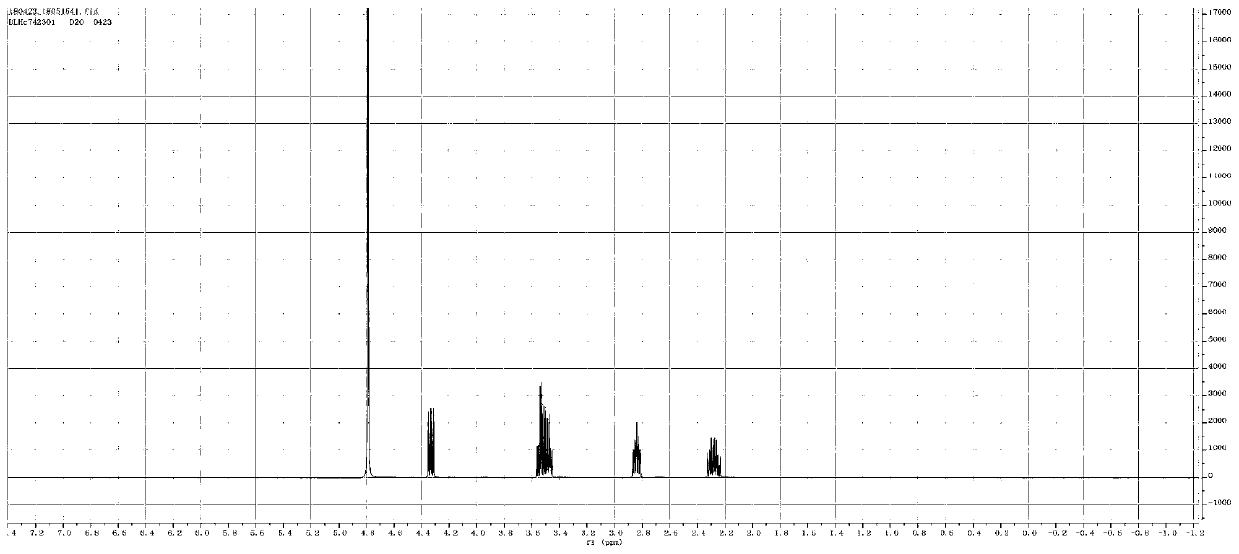

[0046] 44.7g DL-methionine and mass fraction 95% sulfuric acid enter the cathode liquid storage tank 5 through the feed port 4 according to the molar ratio of 1:5, and after mixing, pass into the microchannel reactor 2 under the action of the pump 3 (multi-module microreactor, Shandong Jinde New Material Co., Ltd.), the reaction temperature is 80°C, and the flow rate in the reactor is controlled at 8ml / min. The reaction solution containing DL-homocystine obtained after the reaction is passed into the liquid storage tank 6, and then goes to the storage tank through the feed port 9. 3M hydrochloric acid is added to the liquid tank 6 at one time, and the molar ratio of the added hydrochloric acid to DL-methionine is 4. The liquid storage tank 6 is also provided with an exhaust port to discharge the waste gas in the reaction liquid. The feed l...

Embodiment 2

[0049] The steps are the same as in Example 1, except that 11 microchannel reactors are connected in parallel to the plate and frame electrolyzer, the molar mass ratio of DL-methionine to sulfuric acid is 1:3, and the reaction temperature is 70°C. The internal flow rate is controlled at 5ml / min, and the condition of the electrolysis part is constant. After dehydration and condensation, cooling and drying, the product is analyzed by high performance liquid chromatography. The product yield is 66.2%, and the product purity is 99.1%.

Embodiment 3

[0051] The steps are the same as in Example 1, the difference is that: 4 microchannel reactors are connected in parallel to the plate-and-frame electrolyzer, the molar mass ratio of DL-methionine to sulfuric acid is 1:7, and the reaction temperature is 90°C. The internal flow rate is controlled at 12ml / min, and the conditions of the electrolysis part are constant. After dehydration and condensation, cooling and drying, the product is analyzed by high-performance liquid chromatography. The product yield is 54.8%, and the product purity is 99.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com