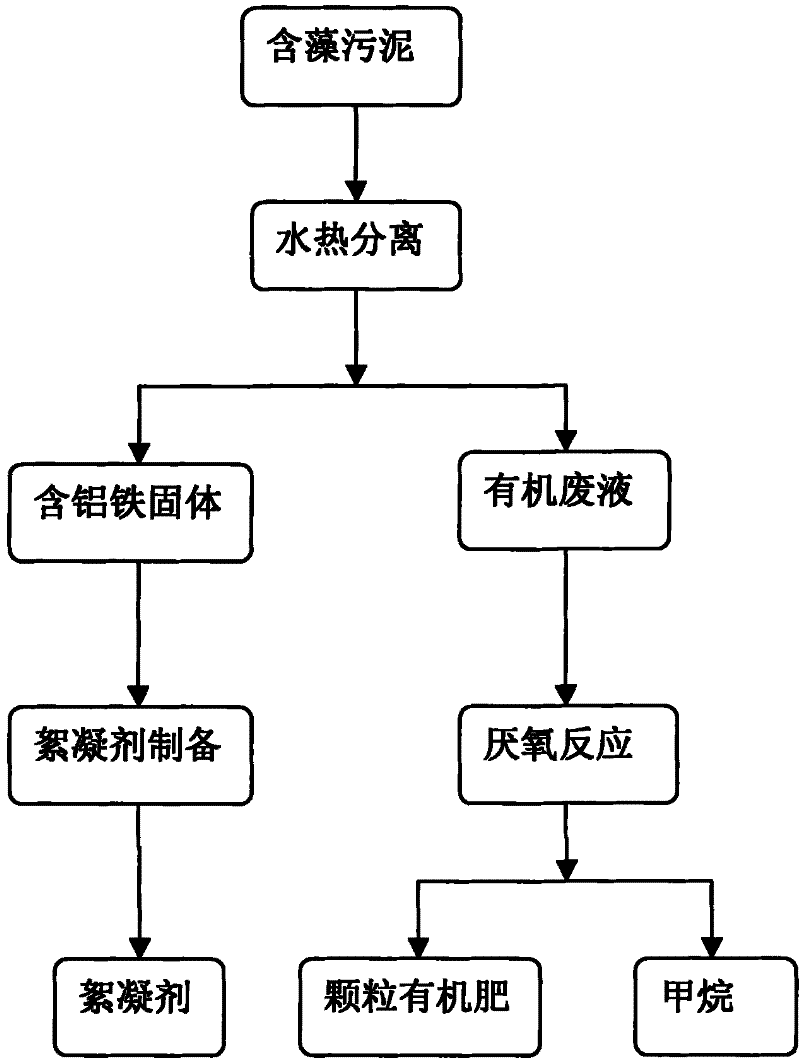

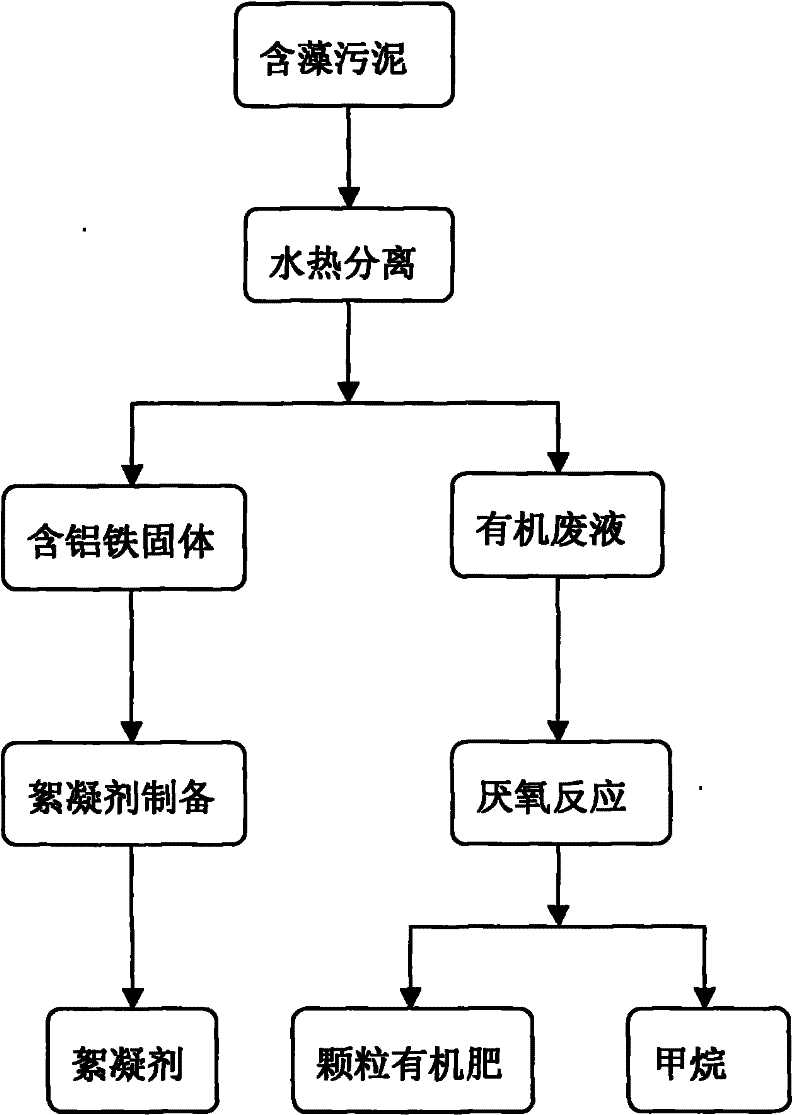

Method for preparing flocculant, fertilizer and methane with algae-containing sludge

A flocculant and compound fertilizer technology, applied in the direction of oxidation treatment of sludge, flocculation/sedimentation water/sewage treatment, application, etc., can solve problems such as insufficient safety, concentration groundwater pollution, environmental impact, etc., and achieve zero discharge and clean production, fast reaction speed and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A. Add the algae-containing sludge with a moisture content of 96%-99% from the sewage treatment plant to the hydrothermal reactor, and then add commercially available hydrogen peroxide with a concentration of 30% by mass. The amount of hydrogen peroxide added is 50mg / L volume of algae-containing sludge, under the pressure of 0.8-1MPa, heated to 150-180°C, and reacted for 1.5-2.5h. After the reaction, let it stand for 30 minutes, the yellowish brown liquid is organic residual waste liquid, its COD is 10000-20000mg / L, and the remaining solid is solid sludge containing aluminum and iron inorganic substances.

[0024] B, flocculant preparation, first dry the solid sludge at 120°C, grind, pass through a 100-mesh sieve, and the under-sieve is sludge powder with a particle size of less than 100 mesh; then add molar concentration of 5mol / L to the under-sieve Hydrochloric acid, the amount of hydrochloric acid added according to the mass ratio of sludge powder: hydrochloric acid ...

Embodiment 2

[0028] The polyaluminum ferric chloride flocculant prepared in Example 1 was used to treat sewage, and the biochemical effluent of a certain sewage plant was used for coagulation experiments. Comparing the polyaluminum ferric chloride of the present invention with the commercially available PAC, it is confirmed that the coagulation effect of the flocculant of the present invention is superior to that of the commercially available PAC.

[0029] The water quality of the biochemical effluent from the sewage plant is as follows: COD is 80mg / L, TP is 3mg / L, and turbidity is 25NTU. Coagulation experiments were carried out with different coagulants (the average water temperature was 20°C and the pH of the water sample was about 6.5), the COD and turbidity of the treated water samples were measured respectively, and the treatment effect under the optimal dosage (60mg / L) was compared : The removal rate of commercially available PAC to biochemical effluent COD, TP and turbidity is about...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com