Method for regulating and controlling magnetic moment arrangement of antiferromagnetic film material

A thin-film material and antiferromagnetic technology, applied in the direction of antiferromagnetic materials, magnetic materials, magnetic objects, etc., can solve the problems of difficult AFM materials and achieve low cost, effective control, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

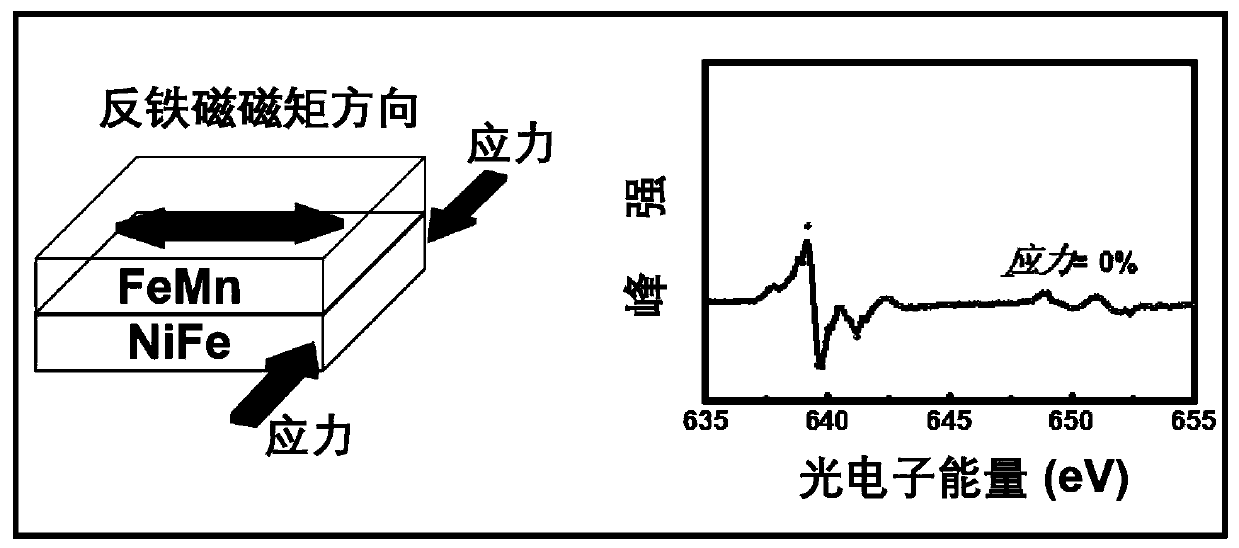

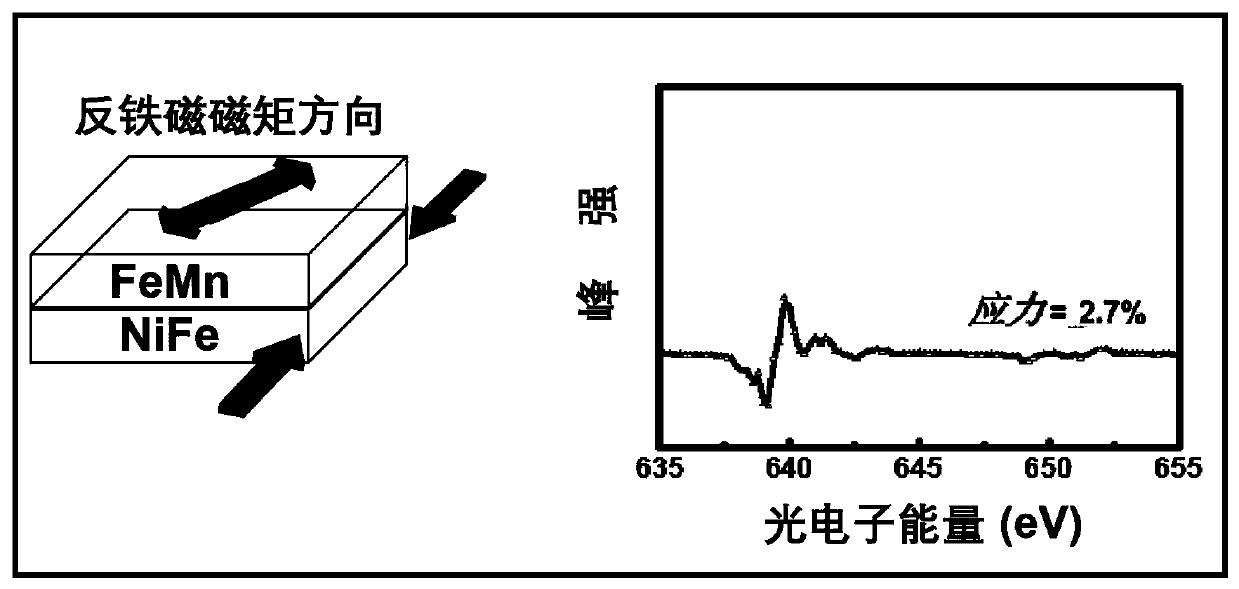

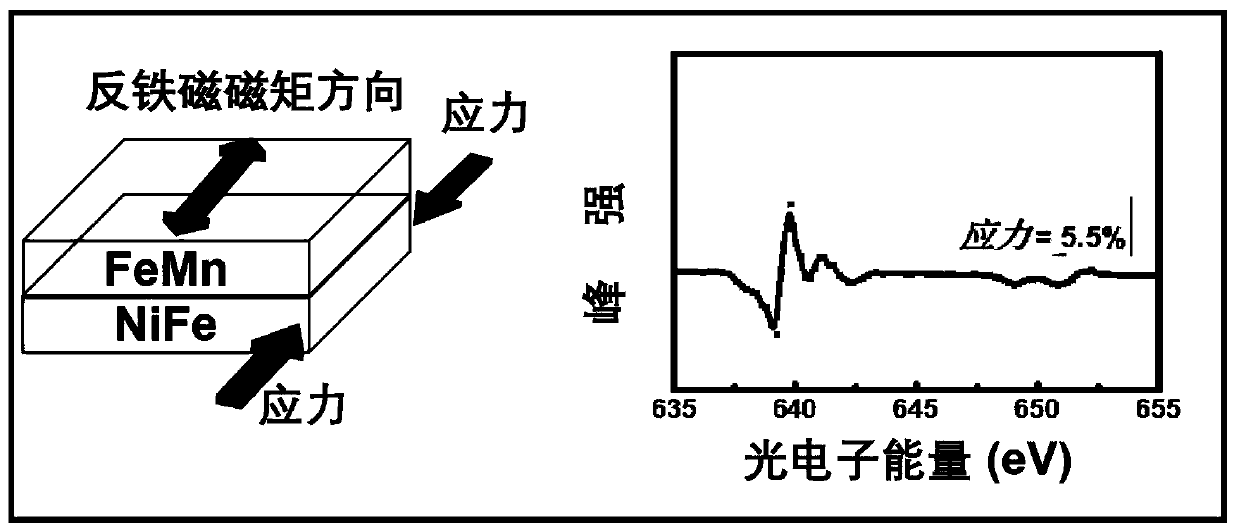

[0017] figure 1 The preparation conditions of the sample are as follows: first, the TiNiNb memory alloy substrate is subjected to pre-stretching treatment, surface polishing and surface argon ion bombardment treatment, the thickness of the TiNiNb substrate is 1.0mm, and the doping amount of Nb in the TiNiNb is 5%, the pre-stretching amount is 10%, the surface roughness after polishing is 0.5 nm, the argon ion bombardment current is 16 mA, and the bombardment time is 0.5 min. Then, utilize magnetron sputtering method, deposit Ta atom (thickness is ), NiFe atoms (thickness is ), FeMn atoms (thickness is ) and Ta atoms (thickness is ), thus preparing TiNi(Nb) substrate / Ta / NiFe / FeMn / Ta For multi-layer films, an in-plane magnetic field of 100Oe needs to be applied when depositing thin films, and the background vacuum of the sputtering chamber is 1×10 -5 , Argon pressure is 0.3Pa during sputtering. Finally, the multilayer film system is heat-treated in a vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com