Preparation method and application of collagen peptide

A collagen peptide and collagen technology, applied in the field of protein preparation, can solve problems such as difficulty in conveniently and timely supplementing protein, elevated cholesterol, cardiovascular diseases, etc., and achieve benefits for production and sales, no clumping, and muscle repair Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

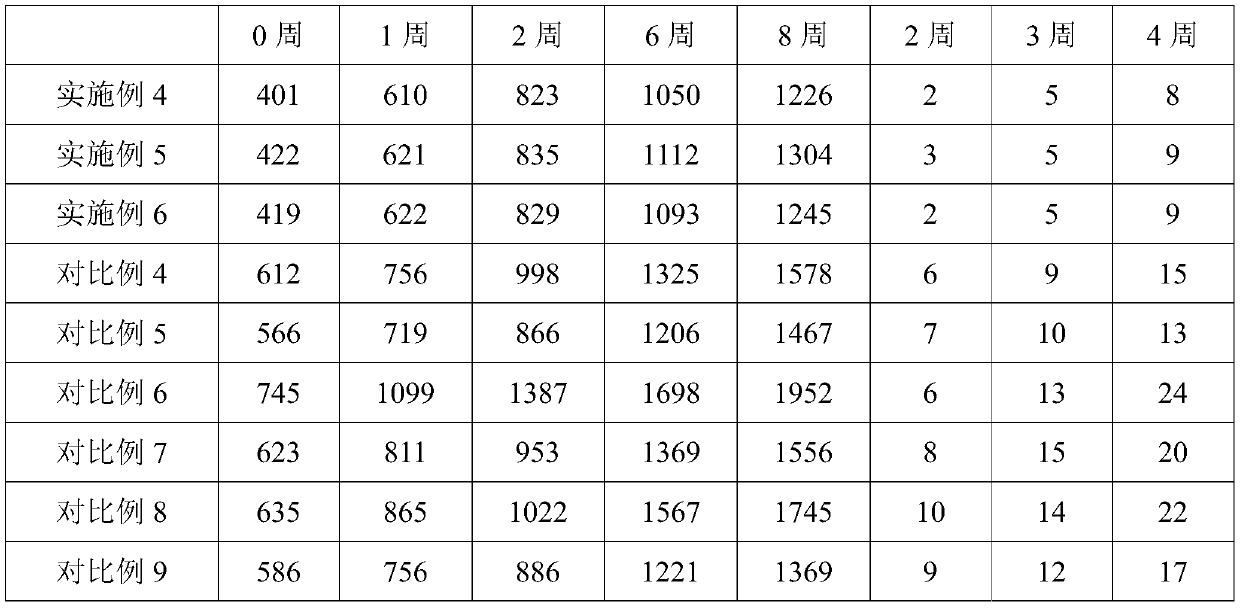

Examples

Embodiment 1

[0070] A preparation method of collagen peptide, comprising the following steps:

[0071] (1) Raw material pretreatment

[0072] The cowhide was cut into small pieces, and at 5°C, the mass fraction was 5% Na 2 CO 3 Degreasing with aqueous solution for 18 hours to obtain degreased cowhide; rinse with 12 times (based on the mass of cowhide, the same below) NaCl solution with a mass fraction of 5% to remove salt-soluble non-collagen components; rinse with distilled water to obtain cowhide particles, and refrigerate at -20°C for later use ;

[0073] (2) Water extracted collagen

[0074] Add cowhide particles to 25 times distilled water, stir and extract at 75°C, collect by filtration every 6 hours and replace hot water, extract until the cowhide is completely dissolved, filter, collect the filtrate, centrifuge, and freeze-dry to obtain collagen samples;

[0075] (3) Preparation of collagen peptides by enzymatic hydrolysis

[0076] Prepare a concentration of 0.6mol / L acetic ac...

Embodiment 2

[0078] A preparation method of collagen peptide, comprising the following steps:

[0079] (1) Raw material pretreatment

[0080] The cowhide was cut into small pieces, and at 2°C, the mass fraction was 2% Na 2 CO 3 Degreasing with aqueous solution for 15 hours to obtain degreased cowhide; washing with 10 times (based on the mass of cowhide, the same below) NaCl solution with a mass fraction of 2% to remove salt-soluble non-collagen components; rinsing with distilled water to obtain cowhide particles, and refrigerating at -10 for later use;

[0081] (2) Water extracted collagen

[0082] Add cowhide particles to 20 times distilled water, stir and extract at 60°C, collect by filtration every 4 hours and replace hot water, extract until the cowhide is completely dissolved, filter, collect the filtrate, centrifuge, freeze-dry, and obtain collagen samples;

[0083] (3) Preparation of collagen peptides by enzymatic hydrolysis

[0084] Prepare a concentration of 0.2mol / L acetic ac...

Embodiment 3

[0086] A preparation method of collagen peptide, comprising the following steps:

[0087] (1) Raw material pretreatment

[0088] The cowhide was cut into small pieces, and at 10°C, the mass fraction was 8% Na 2 CO 3 Degreasing with aqueous solution for 20 hours to obtain degreased cowhide; rinse with 15 times (based on cowhide mass, the same below) NaCl solution with a mass fraction of 8% to remove salt-soluble non-collagen components; rinse with distilled water to obtain cowhide particles, and refrigerate at -30°C for later use ;

[0089] (2) Water extracted collagen

[0090] Add cowhide particles to 30 times distilled water, stir and extract at 80°C, filter and collect every 8 hours and replace hot water, extract until the cowhide is completely dissolved, filter, collect the filtrate, centrifuge, and freeze-dry to obtain collagen samples;

[0091] (3) Preparation of collagen peptides by enzymatic hydrolysis

[0092] Prepare a concentration of 0.8mol / L acetic acid, weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com