Stink inhibitor for microalgae anaerobic biological fermentation and preparation method thereof

A technology of anaerobic organisms and inhibitors, applied in separation methods, chemical instruments and methods, separation of dispersed particles, etc., can solve the problems of adsorption can not play a continuous inhibitory effect, carcinogenic, troublesome operation, etc., to improve adsorption Catalytic degradation ability, reduced replacement frequency, and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

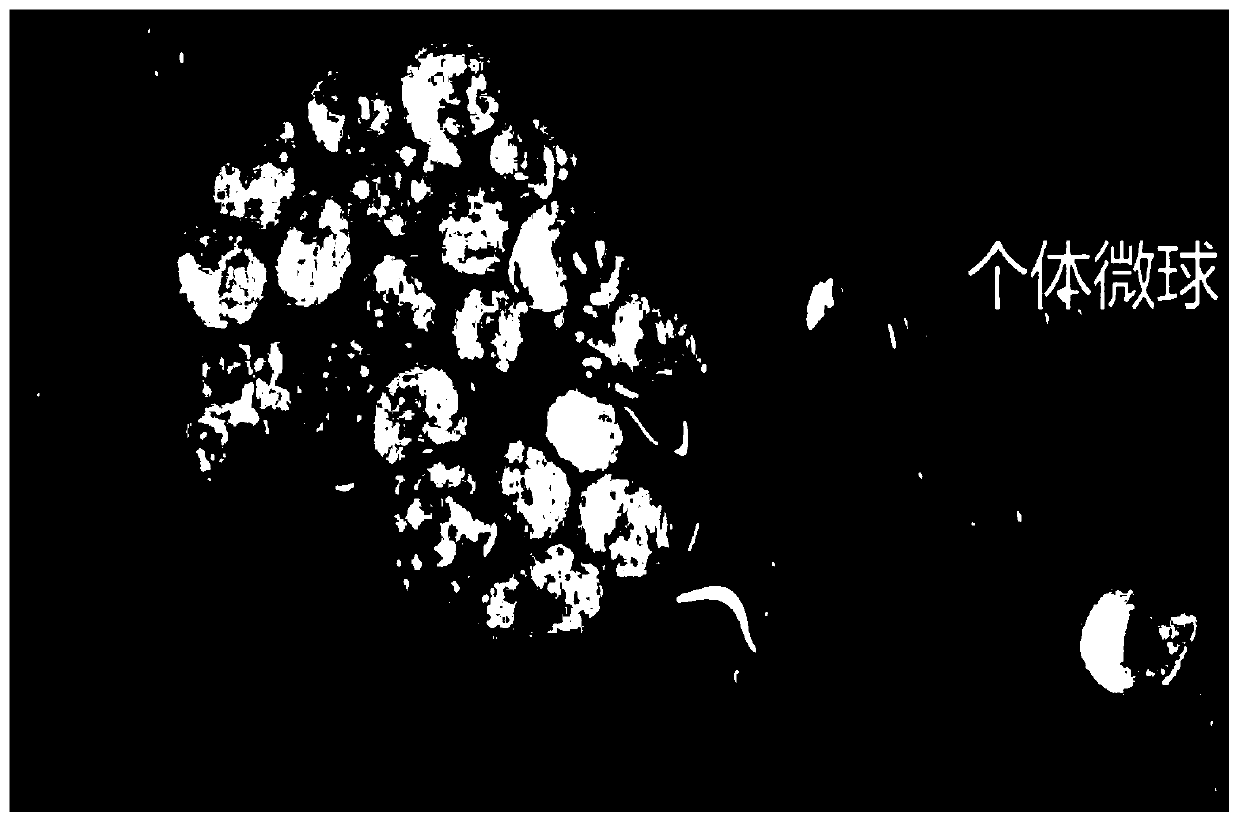

[0027] Prepare 1L of 0.3g / L biological enzyme solution, the mass ratio of cellulase: lipase and yeast hydrolyzate is 1:1:1, add 100 grams of polyvinyl alcohol with a polymerization degree of 1650 to the 0.3g / L biological enzyme solution , heated to 30-40°C and stirred for 5 hours to complete the modification process, the modified solution was passed through the microtube nozzle at a rate of 70 drops per minute (about 100 microliters per drop), and the mass concentration was 4 % dilute boric acid solution, filter and wash the obtained microsphere products, and select microspheres with a diameter of 0.5cm-1cm, and activate them with phosphate buffer (pH=7, 0.1M) at 35±2°C 3 times, 60 minutes each time.

[0028] Add 100g of the above-mentioned malodor inhibitor prepared by anaerobic fermentation into a 10L microalgae anaerobic fermentation reactor with a solid content rate lower than 5%, and perform anaerobic fermentation at 35°C for 25 days, using three-point comparison every da...

Embodiment 2

[0031] Prepare 5L of 0.5g / L biological enzyme solution, the mass ratio of cellulase: lipase and yeast hydrolyzate is 1:1:1, add 500 grams of polyvinyl alcohol with a polymerization degree of 1850 to the 0.3g / L biological enzyme solution , heated to 30-40°C and stirred for 5 hours to complete the modification process, the modified solution was passed through the nozzle at a rate of 70 drops per minute (about 100 microliters per drop), and the mass concentration was 4% Dilute boric acid solution, filter and wash the obtained microsphere product, and select microspheres with a diameter of 0.5cm-1cm, and activate them three times with phosphate buffer (pH=7, 0.1M) at 35±2°C. 60 minutes each time.

[0032] Use 100L of microalgae with a solid content of about 7% as raw material to carry out anaerobic biological fermentation reaction, and use 500g of odor inhibitor prepared by the above method as an auxiliary material, and add it to the waste gas purification absorber of the microalg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption | aaaaa | aaaaa |

| Adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com