Preparation process and application of composite titaniferous solution for waste gas catalytic purification

A technology of catalytic purification and preparation process, applied in the field of materials, can solve the problems of increasing the cost of environmental protection of enterprises, large particle size of titanium dioxide, inability to coat into the wall-flow carrier, etc. The effect of increasing the contact area and increasing the efficiency of sulfur removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

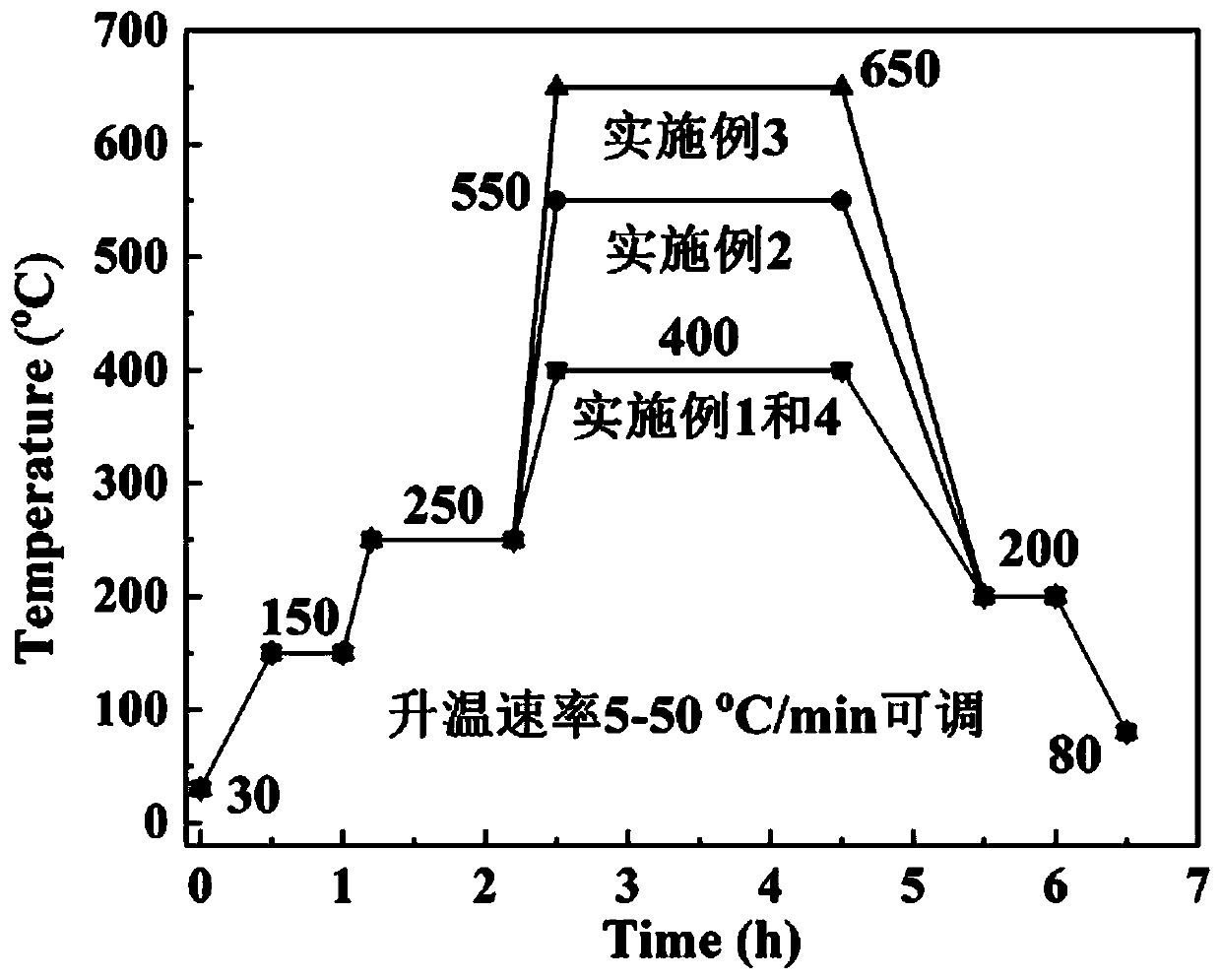

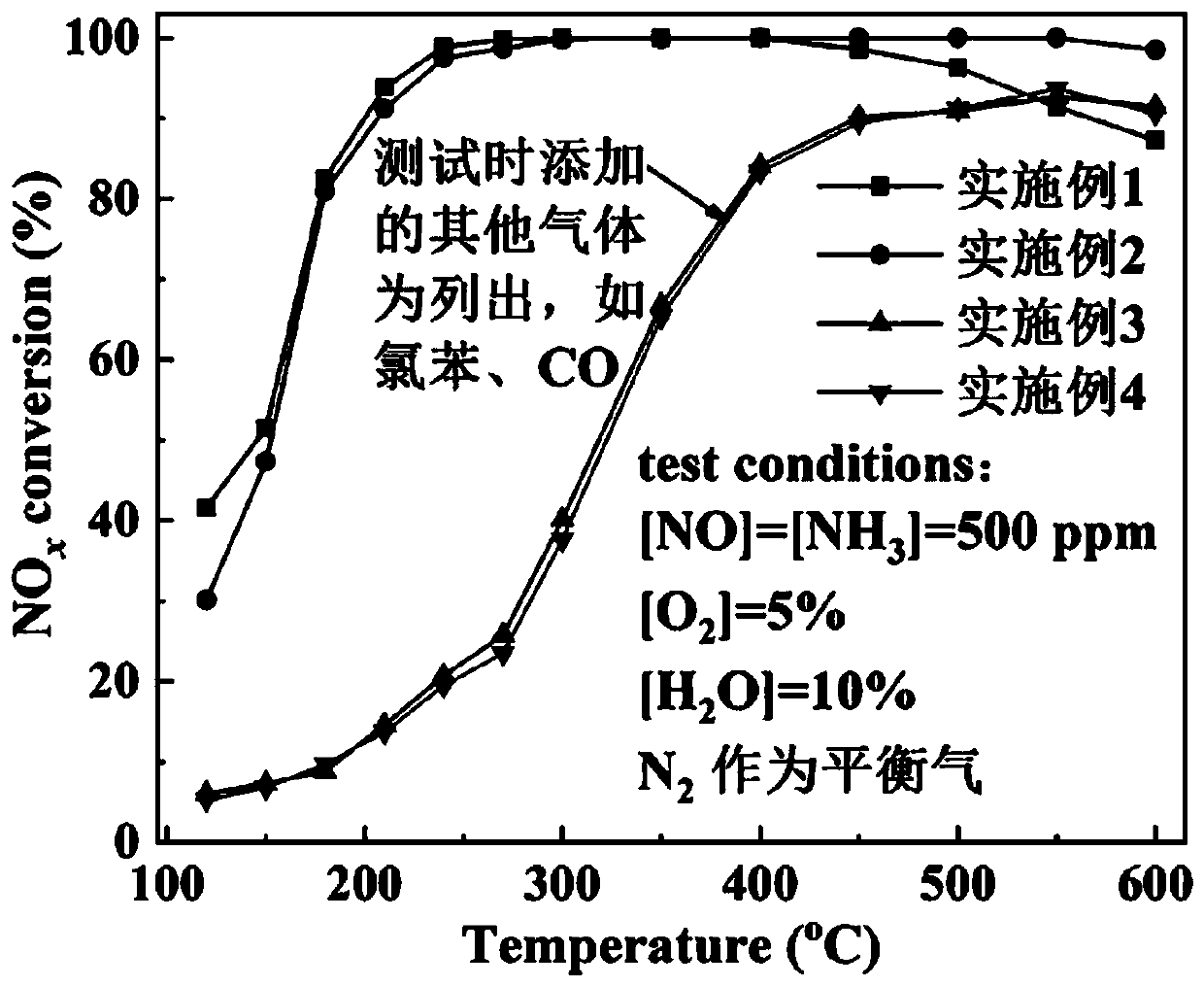

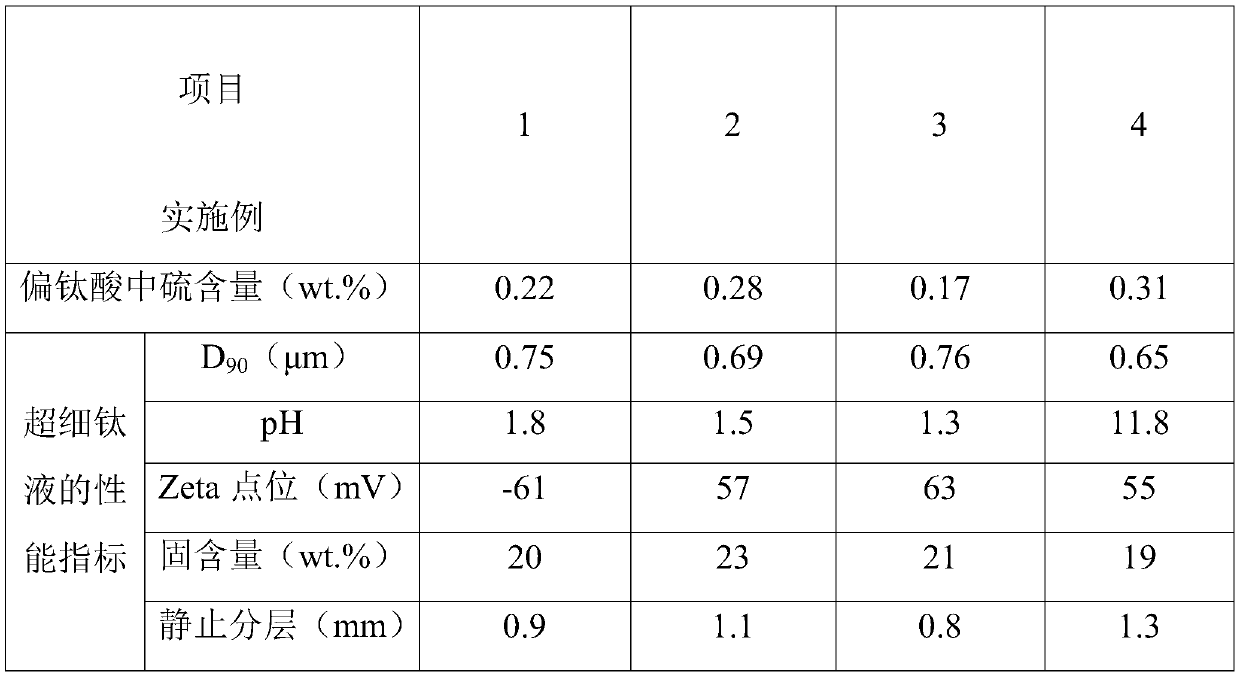

[0031] 1. Metatitanic acid desulfurization: In the bubbling reactor, the metatitanic acid produced by the sulfuric acid method is diluted with water to form a slurry; then the air containing monoethanolamine is pumped from the bubbling ports at the bottom of both sides of the reactor into the constantly stirring In the slurry, after reacting for 6 hours, the slurry was transferred to a plate and frame filter press, filtered and washed to obtain a titanium cake, and the sulfur content in the obtained titanium cake is shown in Table 1;

[0032]2. Titanium cake grinding: In the grinding machine, after adding concentrated nitric acid and polyethylene glycol, under the condition of a line speed of 10m / s, after grinding for 6 hours, the ultrafine titanium liquid required by the regulations (see Table 1) is obtained, and then transferred to the stirring tank;

[0033] 3. Addition of active substances: Transfer part of the ground ultrafine titanium liquid to a stirring preparation ket...

Embodiment 2

[0037] 1. Metatitanic acid desulfurization: In the bubbling reactor, the metatitanic acid produced by the sulfuric acid method is diluted with water to form a slurry; then the air containing ethylenediamine is pumped from the bubbling ports at the bottom of both sides of the reactor to keep stirring In the slurry, after reacting for 6h, the slurry was transferred to a plate and frame filter press, filtered and washed to obtain a titanium cake, and the sulfur content in the gained titanium cake was shown in Table 1;

[0038] 2. Titanium cake grinding: In the grinding machine, after adding concentrated nitric acid and polyethylene glycol, under the condition of a linear speed of 10m / s, after grinding for 5 hours, obtain the ultrafine titanium liquid required by the regulations (see Table 1), and then transfer to the stirring tank;

[0039] 3. Addition of active substances: transfer part of the ground ultrafine titanium liquid to a stirring preparation kettle, then add ammonium m...

Embodiment 3

[0043] 1. Metatitanic acid desulfurization: In the bubbling reactor, the metatitanic acid produced by the sulfuric acid method is diluted with water to form a slurry; then the air containing urea is pumped into the constantly stirring slurry from the bubbling ports at the bottom of both sides of the reactor After reacting for 6 hours, the slurry was transferred to a plate and frame filter press, filtered and washed to obtain a titanium cake, and the sulfur content in the obtained titanium cake was shown in Table 1;

[0044] 2. Titanium cake grinding: In the grinding machine, after adding concentrated nitric acid and HPMA, under the condition of a linear speed of 12m / s, after grinding for 6 hours, obtain the required ultrafine titanium liquid (see Table 1), and then transfer to the stirring tank middle;

[0045] 3. Active material addition: transfer part of the ground ultrafine titanium solution to a stirring preparation kettle, then add aluminum glue, cerium nitrate, zirconium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com