Water-reducing bulk polymerization solid polycarboxylate superplasticizer, and preparation method, use method and application thereof

A technology of bulk polymerization and polycarboxylate, which is applied in the field of water-reducing bulk polymerization solid polycarboxylate water reducer and its preparation, use and application, can solve problems such as poor effect, non-environmental protection, and difficult reaction process. Achieve the effect of good initial slump, good slump retention effect and high water reducing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

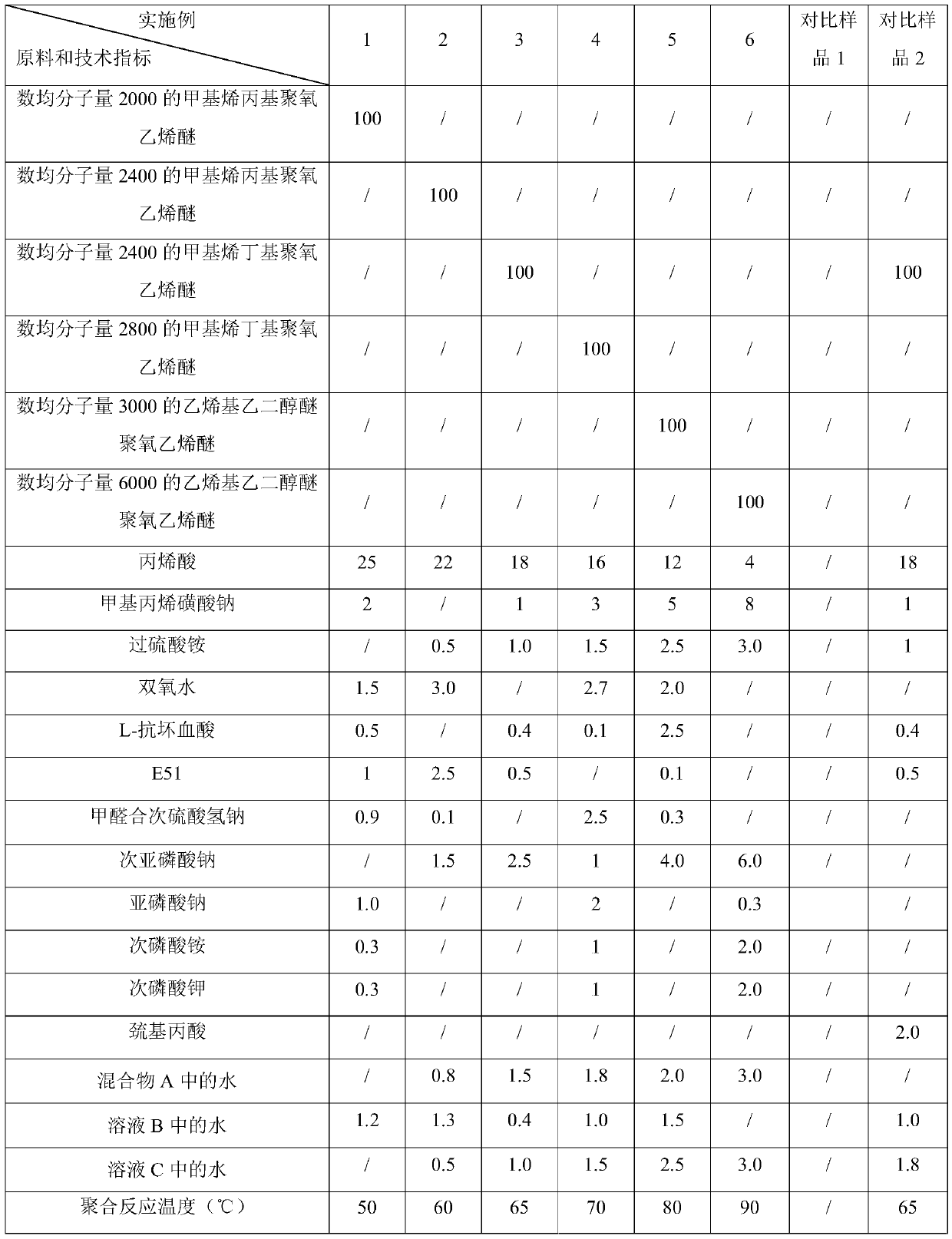

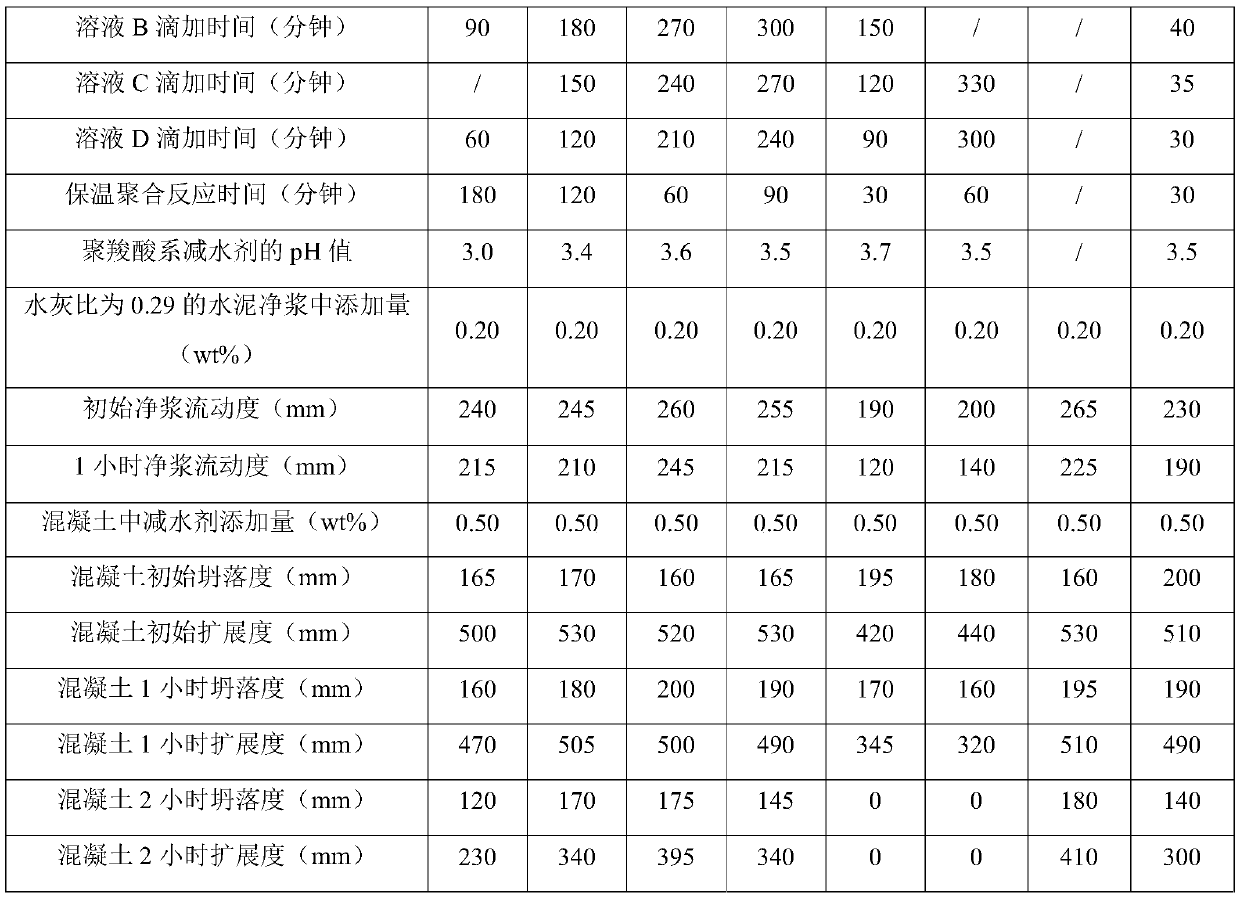

[0073] The present invention also provides a preparation method of the water-reducing bulk polymerized solid polycarboxylate water-reducer derived from environmentally friendly and odorless raw materials, which includes the following steps: adding 10% of acrylic acid to the mixture A under stirring conditions %-50% of acrylic acid and sodium methacrylic sulfonate, after stirring evenly, add hydrogen peroxide, then dropwise add solution B, solution C, solution D to carry out polymerization reaction, after aging for a predetermined period of time, the liquid product after the heat preservation is completed Quickly pour it on the aluminum foil paper, cool and make tablets, wait for the liquid product to cool and solidify naturally, and obtain a water-reducing bulk polymerized solid polycarboxylate water-reducer with a solid content of 94.5wt% to 100wt% derived from environmentally friendly and odorless raw materials ;

[0074] The mixture A is obtained by mixing unsaturated polye...

Embodiment 1

[0100] (1) Preparation before polymerization:

[0101] Preparation of mixture A: Weigh 100 parts by weight of methallyl polyoxyethylene ether with a number average molecular weight of 2000, put it into a polymerization reactor, heat it to 50°C, and when it is in a molten state, start stirring to accelerate melting. When it is completely melted into a liquid, add 1.0 parts by weight of sodium phosphite, 0.3 parts by weight of ammonium hypophosphite, and 0.3 parts by weight of potassium hypophosphite, stir evenly, keep at 50°C, and set aside;

[0102] Preparation of solution B: Weigh 0.5 parts by weight of L-ascorbic acid, 1.0 parts by weight of E51, 0.9 parts by weight of sodium formaldehyde sulfoxylate and 1.2 parts by weight of water, stir evenly, and prepare to add dropwise;

[0103] Preparation of solution D: Weigh 12.5 parts by weight of acrylic acid and prepare dropwise;

[0104] (2) Polymerization: step (1) put into the polymerization reactor of mixture A, start stirrin...

Embodiment 2

[0107] (1) Preparation before polymerization:

[0108] Preparation of mixture A: Weigh 100 parts by weight of methallyl polyoxyethylene ether with a number average molecular weight of 2400, put it into a polymerization reactor, heat it to 60°C, and when it is in a molten state, start stirring to accelerate melting. When it completely melts into a liquid, add 1.5 parts by weight of sodium hypophosphite and 0.8 parts by weight of water, stir evenly, keep at 60°C, and set aside;

[0109] Preparation of Solution B: Weigh 2.5 parts by weight of E51, 0.1 parts by weight of sodium formaldehyde sulfoxylate and 1.3 parts by weight of water, stir evenly, and prepare dropwise;

[0110] Preparation of Solution C: Weigh 0.5 parts by weight of ammonium persulfate and 0.5 parts by weight of water, stir evenly, and prepare for dropwise addition;

[0111] Preparation of solution D: Weigh 18.7 parts by weight of acrylic acid and prepare dropwise;

[0112] (2) Polymerization: step (1) put into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com