A kind of ionic liquid catalyst for synthesizing bio-based polycarbonate and method for synthesizing bio-based polycarbonate

A technology for synthesizing bio-based polycarbonate, applied in the field of catalysis, can solve the problems of difficulty in synthesizing high-molecular-weight bio-based polycarbonate, difficult activation of internal hydroxyl groups, low internal hydroxyl activity, etc., so as to shorten the reaction time and improve the reaction activity. , the effect of high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

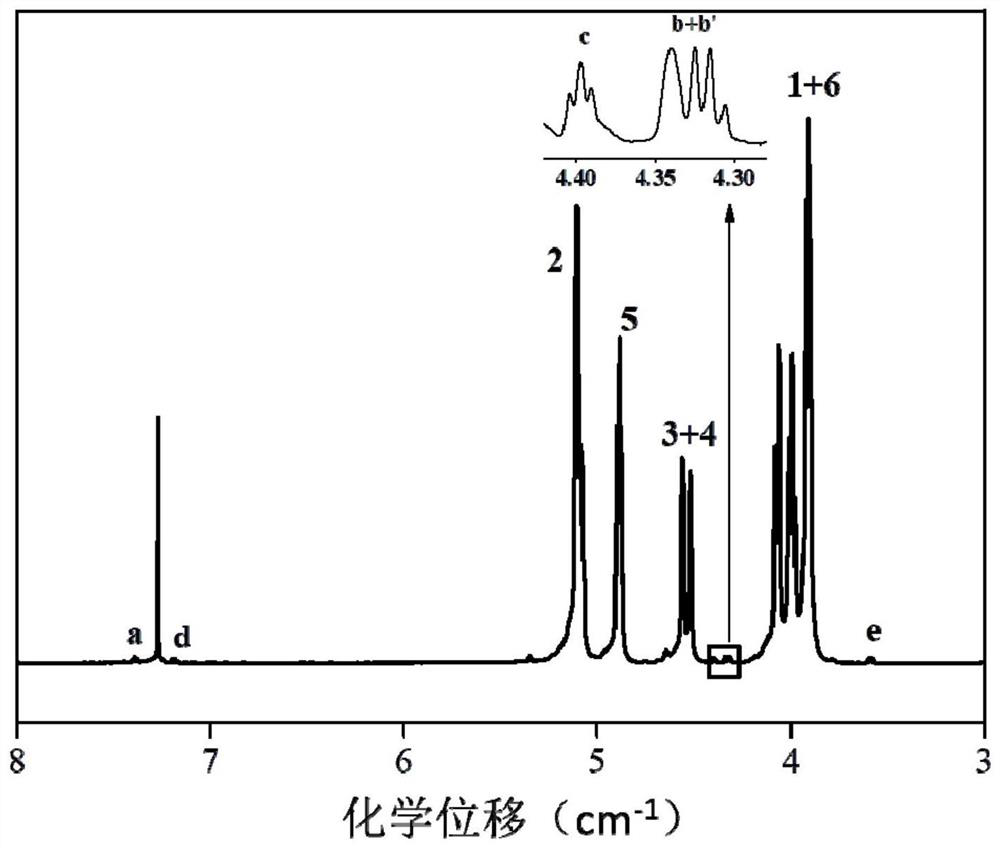

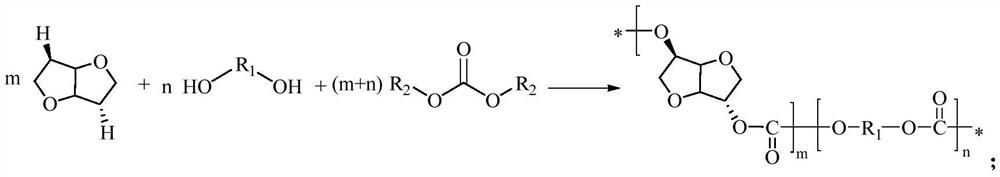

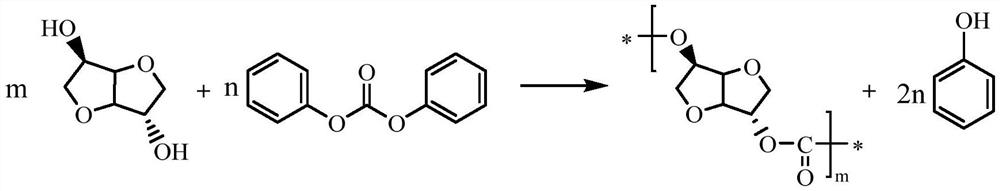

[0036] Take dihydroxyl compound and carbonic acid diester as the equation of raw material synthesis polycarbonate reaction:

[0037]

Embodiment 2

[0041] The difference with Example 1 is that the catalyst used is 5×10 -5 mol (relative to the amount of isosorbide substance) of tetrabutylphosphinelysine ([P 4444 ][Lys]), the yield of the resulting bio-based polycarbonate was 97%, the number average molecular weight was 85000g / mol, and the molecular weight distribution was 1.54.

Embodiment 3

[0043] The difference with Example 1 is that the catalyst used is 5×10 -5 mol (relative to the amount of isosorbide substance) of tetraethylammonium lysine ([N 2222 ][Lys]), the yield of the obtained bio-based polycarbonate was 96%, the number average molecular weight was 58000g / mol, and the molecular weight distribution was 1.62.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com