High-performance brake pad and machining method thereof

A brake pad and high-performance technology, applied in the field of high-performance brake pads and their processing, can solve the problems that cannot be achieved, cannot be modified, cannot meet the performance requirements of brake pads, etc., and can improve wear resistance and corrosion resistance. Performance, mechanical performance improvement, the effect of meeting the requirements of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

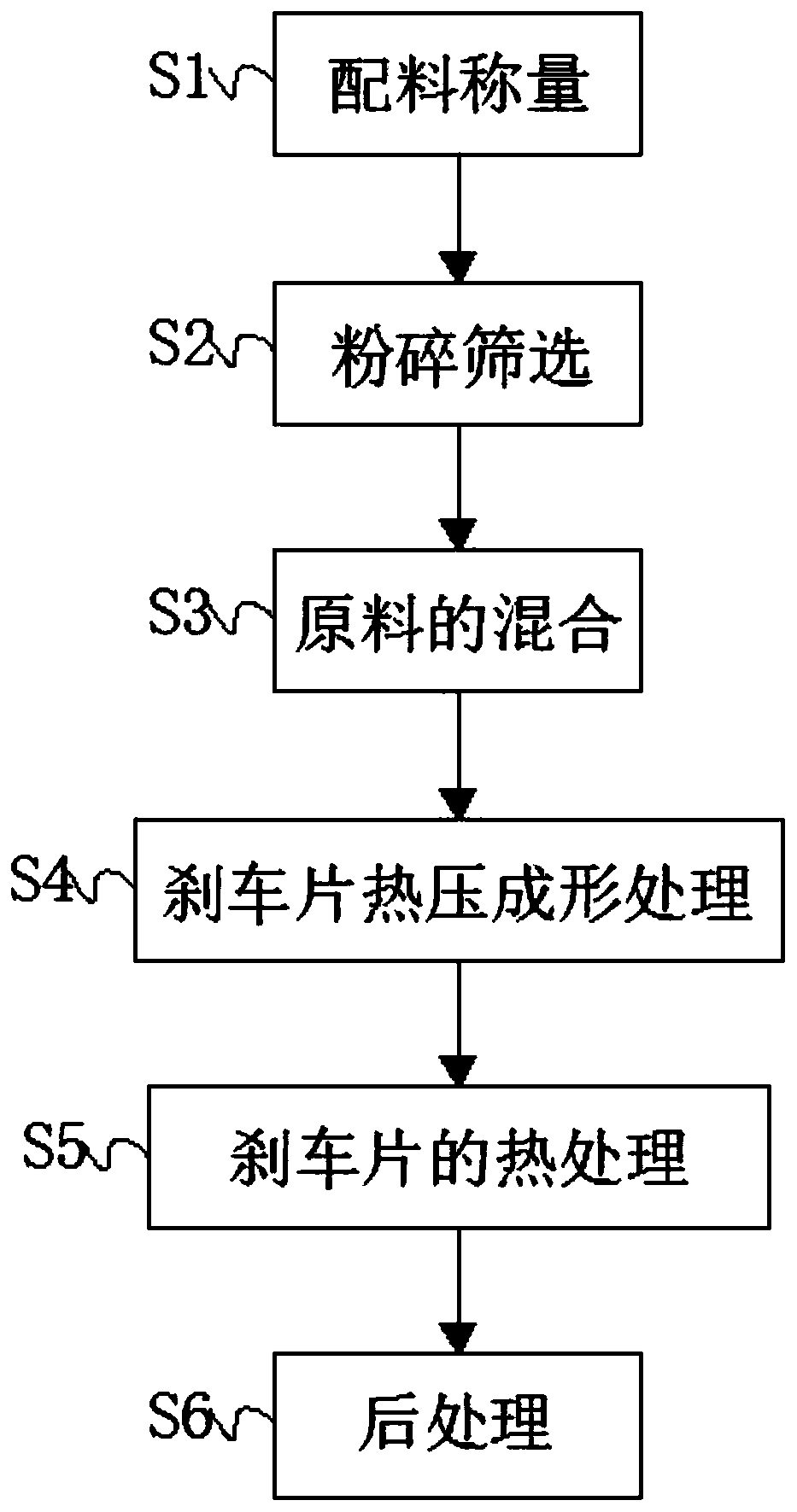

Method used

Image

Examples

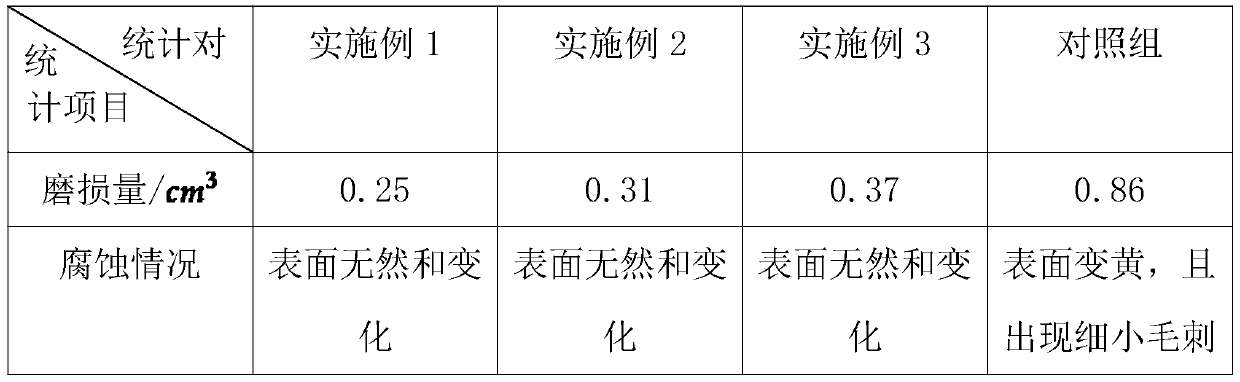

Embodiment 1

[0030] A high-performance brake pad, the raw materials of which include by weight: 15 parts of cashew oil triepoxy resin, 15 parts of silicone resin, 7 parts of polyamide resin, 7 parts of steel fiber, 4 parts of friction modifier, modified silicon 2 parts of limestone, 2 parts of modified sepiolite, 2 parts of copper powder, 2 parts of barium sulfate, 2 parts of calcined petroleum coke, 2 parts of sand grain powder, 4 parts of wear-resistant reinforcing filler, 2 parts of high manganese alloy fiber, 4 parts of corrosion-enhancing filler and 2 parts of lubricant, the friction modifier is a combination of calcium sulfate, sodium fluoride, black iron, graphite and molybdenum disulfide, and the modified wollastonite is obtained by using stearin with a diameter of 0.018mm The acid-modified fine particles are mixed with wollastonite, and the modified sepiolite is obtained by mixing stearic acid-modified coarse particles with a diameter of 0.28 mm and fibrous sepiolite. The wear-resi...

Embodiment 2

[0039] A high-performance brake pad, the raw materials of which include by weight: 10 parts of cashew nut oil triepoxy resin, 10 parts of silicone resin, 10 parts of polyamide resin, 10 parts of steel fiber, 5 parts of friction modifier, modified silicon 3 parts of limestone, 3 parts of modified sepiolite, 3 parts of copper powder, 3 parts of barium sulfate, 3 parts of calcined petroleum coke, 3 parts of sand grain powder, 5 parts of wear-resistant reinforcing filler, 3 parts of high manganese alloy fiber, 5 parts of corrosion-enhancing filler and 3 parts of lubricant, the friction modifier is calcium sulfate, and the modified wollastonite is prepared by mixing wollastonite with stearic acid-modified fine particles with a diameter of 0.018 mm. The high-strength sepiolite is made by mixing stearic acid-modified coarse particles with a diameter of 0.28mm and fibrous sepiolite. The wear-resistant reinforcing filler is corundum, and the corrosion-resistant reinforcing filler is pol...

Embodiment 3

[0048] A high-performance brake pad, the raw materials of which include by weight: 20 parts of cashew oil triepoxy resin, 20 parts of silicone resin, 5 parts of polyamide resin, 5 parts of steel fiber, 3 parts of friction performance regulator, modified silicon 1 part of limestone, 1 part of modified sepiolite, 1 part of copper powder, 1 part of barium sulfate, 1 part of calcined petroleum coke, 1 part of sand grain powder, 3 parts of wear-resistant reinforcing filler, 1 part of high manganese alloy fiber, 3 parts of corrosion-enhancing filler and 1 part of lubricant, the friction modifier is molybdenum disulfide, and the modified wollastonite is prepared by mixing wollastonite with stearic acid-modified fine particles with a diameter of 0.018mm, and Modified sepiolite is prepared by mixing stearic acid-modified coarse particles with a diameter of 0.28mm and fibrous sepiolite. The wear-resistant reinforcing filler is toughened aluminum oxide, and the corrosion-resistant reinfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com