Wear-resistant engineering plastic and preparation method thereof

An engineering plastics, unsaturated technology, applied in the field of wear-resistant engineering plastics and its preparation, can solve the problems of low plastic yield, increased use cost, and reduced service life, achieving low production costs, improved service life, and increased service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

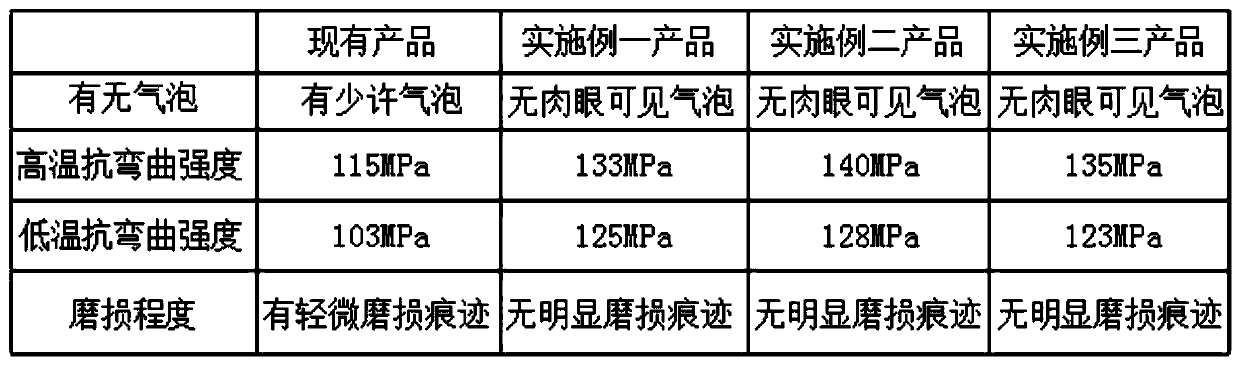

Examples

Embodiment 1

[0028] Step 1: Take 70 parts by weight of unsaturated polyester, 65 parts of polyethylene terephthalate, 22 parts of semi-aromatic nylon PA6T, 11 parts of polytetrafluoroethylene, and 15 parts of potassium titanate whisker reinforcement , 4 parts of butyltin mercaptide stabilizer, 3 parts of additives, 1.2 parts of coupling agent, 0.3 parts of antioxidant and 1.4 parts of lubricant, lubricant is the composition of liquid paraffin and glyceryl monostearate, and antioxidant is 1010. For the composition in DLT and MB, the additive is specifically nano-copper powder, and the raw materials of each component are fully pre-dried. The pre-drying time is 7.5 hours, and the ambient temperature during pre-drying is 90°C;

[0029] Step 2: Detect the pre-dried raw materials, use raw materials with a water content lower than 0.5%, heat each dried raw material through equipment, and stir at a temperature of 300°C for 30 minutes;

[0030] Step 3: The mixed raw material melt is extruded into f...

Embodiment 2

[0033]Step 1: Take 68 parts by weight of unsaturated polyester, 77 parts of polyethylene terephthalate, 23 parts of semi-aromatic nylon PA6T, 12 parts of polytetrafluoroethylene, 17 parts of potassium titanate whisker reinforcement, 4 parts of butyltin mercaptide stabilizer, 2 parts of additives, 1.5 parts of coupling agent, 0.5 parts of antioxidant and 1.5 parts of lubricant, lubricant is the composition of polyethylene wax and glyceryl monostearate, and antioxidant is Compositions in BHT, TNP and MB, the additive is specifically nano-copper powder, and the raw materials of each component are fully pre-dried. The pre-drying time is 7 hours, and the temperature of the environment during pre-drying is 95°C;

[0034] Step 2: Detect the pre-dried raw materials, use raw materials with a water content lower than 0.5%, heat each dried raw material through equipment, and stir at a temperature of 295°C for 25 minutes;

[0035] Step 3: The mixed raw material melt is extruded into filam...

Embodiment 3

[0038] Step 1: Take 68 parts by weight of unsaturated polyester, 69 parts of polyethylene terephthalate, 30 parts of semi-aromatic nylon PA6T, 10 parts of polytetrafluoroethylene, 17 parts of potassium titanate whisker reinforcement, 3 parts of butyltin mercaptide stabilizer, 4 parts of additives, 1.1 parts of coupling agent, 0.4 parts of antioxidant and 2.1 parts of lubricant, lubricant is the composition of liquid paraffin and glyceryl monostearate, and antioxidant is 1010 , the composition of DLTP and TNP, the additive is specifically nano-copper powder, and the raw materials of each component are fully pre-dried, the pre-drying time is 6 hours, and the temperature of the environment during pre-drying is 92 ° C;

[0039] Step 2: Detect the pre-dried raw materials, use raw materials with a water content lower than 0.5%, heat each dried raw material through equipment, and stir at a temperature of 310°C for 33 minutes;

[0040] Step 3: The mixed raw material melt is extruded i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com