A kind of cobalt-phosphine catalyst and its preparation method and application

A technology of catalyst and cobalt source, which is applied in the field of cobalt-phosphine catalyst and its preparation, can solve the problems of high price, easy oxidation by air, and decreased yield of target catalyst, and achieve cost reduction, simplified composition, and avoiding the introduction of cocatalysts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] An aspect of the embodiments of the present invention provides a method for preparing a cobalt-phosphine catalyst, which includes:

[0022] In a reducing atmosphere, the first homogeneously mixed reaction system including cobalt source, phosphine ligand and solvent is reacted at 70-140° C. for 1-6 hours, and the cobalt-phosphine catalyst is obtained through post-treatment.

[0023] In some embodiments, the preparation method includes: adding a cobalt source, a phosphine ligand and a solvent into a reaction vessel and mixing them uniformly to form the first uniformly mixed reaction system, and introducing a reducing gas into the reaction vessel , keeping the pressure in the reaction vessel at 2-8MPa, then reacting at 70-140° C. for 1-6 hours, and then post-processing to prepare the cobalt-phosphine catalyst.

[0024] Further, the cobalt source includes cobalt isooctanoate and / or cobalt naphthenate, but is not limited thereto.

[0025] Further, the cobalt source is deriv...

Embodiment 1

[0056] The preparation method of the cobalt-phosphine catalyst of the present embodiment is as follows:

[0057] Add 40g toluene, 60g cobalt isooctanoate (10% cobalt content) and 18.9g tributylphosphine respectively in the stainless steel autoclave of 300mL, with 1MPa H 2 / CO(1:1) is replaced 4 times, filled with H 2 / CO (1:1) 2MPa, add CO to the total pressure of 3MPa, slowly raise the temperature to 120°C and keep it for 2h, during the reaction, 3MPa of CO has been fed to keep the reaction at a constant pressure. After the reaction, the temperature was lowered, and the slurry was filtered after pressure relief, and washed with toluene until the filtrate was clear. The filter cake was transferred to a vacuum drying oven at 40° C. for 20 h, and the yield of the cobalt-phosphine catalyst (1) was calculated to be about 65.1% after weighing.

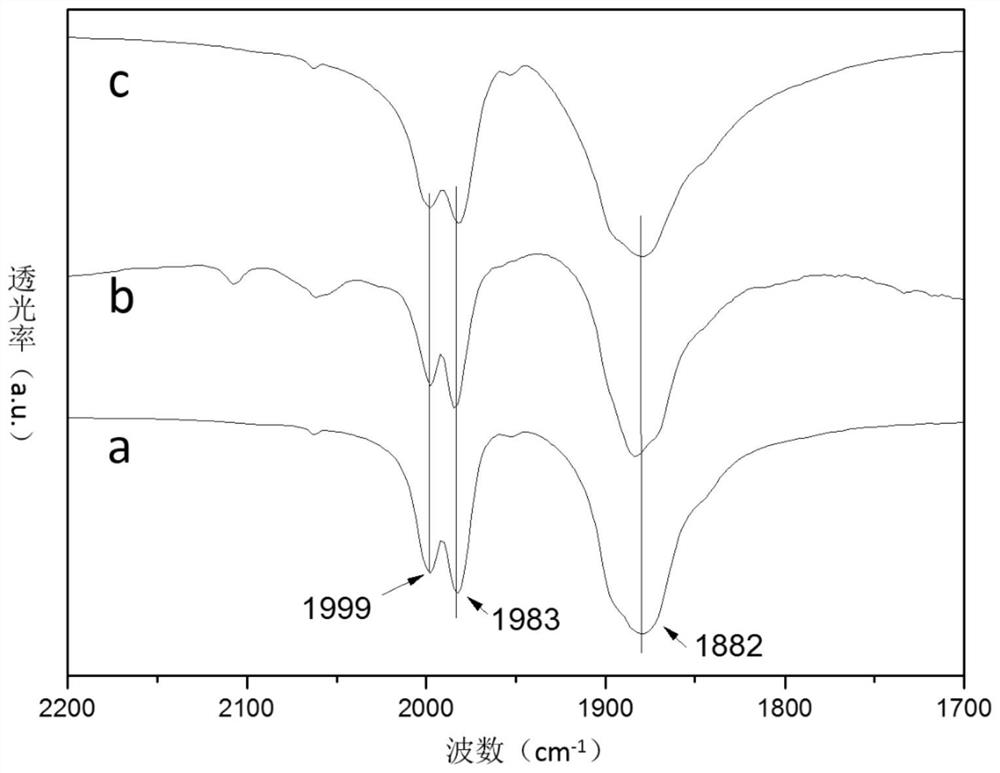

[0058] figure 1 It is the infrared spectrum of the catalyst (1) obtained in this embodiment, wherein, a is the infrared spectrum of the...

Embodiment 2

[0060] The preparation method of this example is basically the same as that of Example 1, except that the toluene in Example 1 is changed to 40 g of petroleum ether, CO is added to a total pressure of 5 MPa, and the temperature is slowly raised to 100° C. and maintained for 1.5 hours. The yield of cobalt-phosphine catalyst (1) obtained in this example is about 73.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com