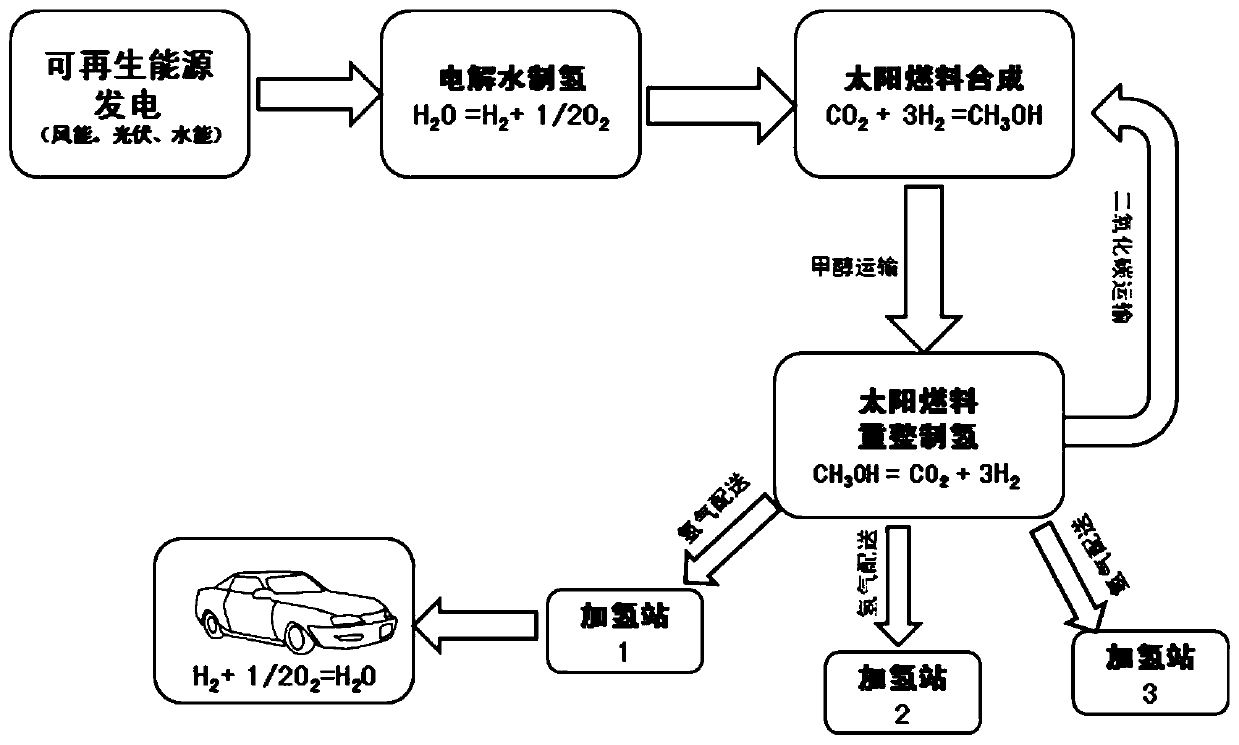

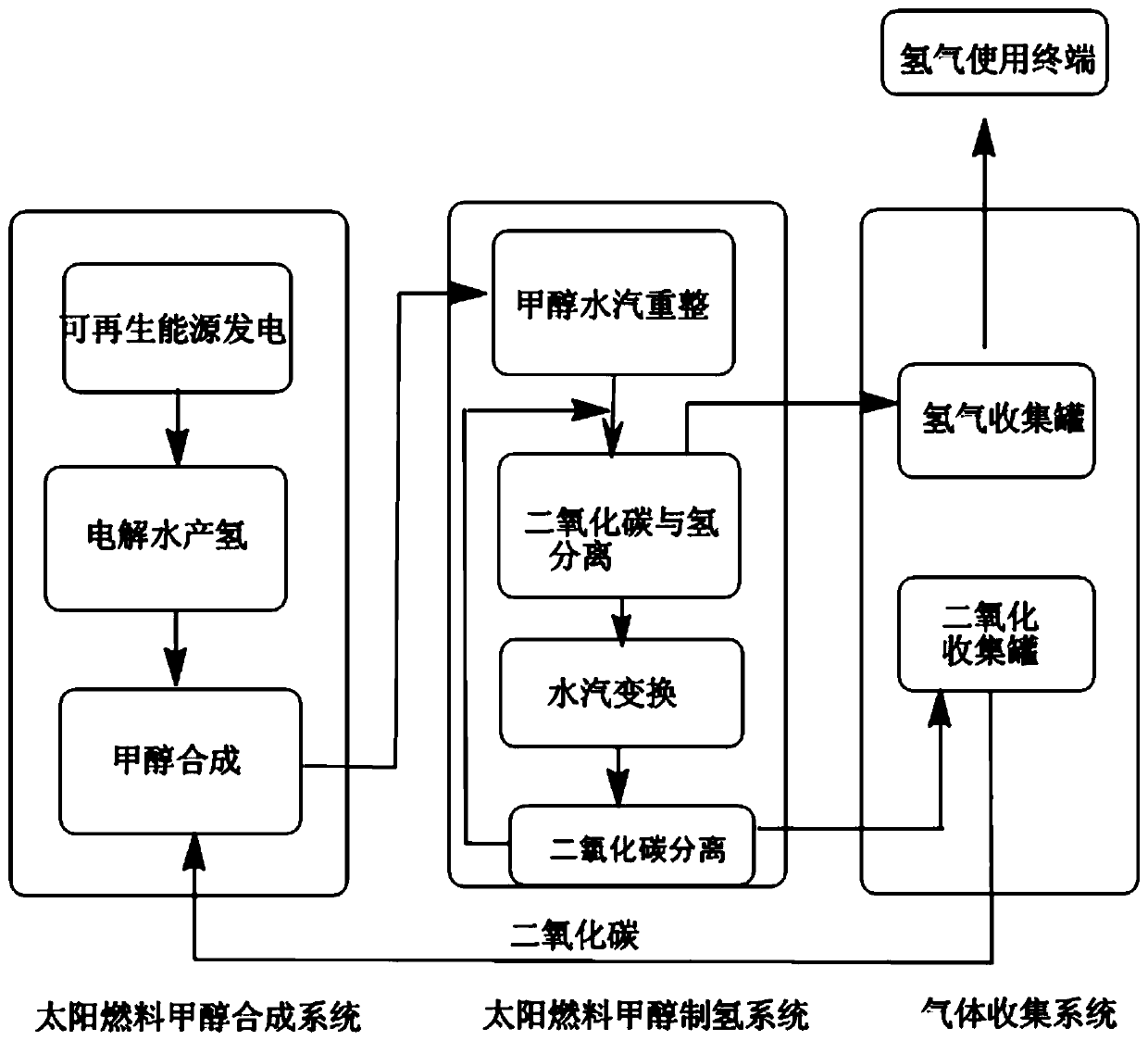

Hydrogen production system based on solar fuel methanol-water reforming

A technology for hydrogen production from reforming and methanol production, which is applied in the fields of biofuels, hydroxyl compound preparation, hydrogen, etc., can solve problems such as the inability to achieve zero carbon emissions, and achieve the effect of sustainable development and ecological civilization construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 7~9 2

[0071] Embodiment 7~9 carbon dioxide and hydrogen separation

[0072] The mixed gas composition after methanol reforming in embodiment 1 is H 2 (73%) CO 2 (24%), CO (2%) passes through the carbon dioxide and hydrogen separation module, taking palladium membrane separation as an example, its working conditions and effects are shown in Table 2

[0073] Table 2

[0074]

[0075] a: Hydrogen separation efficiency = (n 分离后的物质的量 / n 分离前的物质的量 )×100

[0076] Using palladium membrane technology to separate hydrogen, the purity of hydrogen can reach 99.999%. It can directly enter the hydrogen collection tank and supply the hydrogen use terminal.

Embodiment 10~12

[0077] Embodiment 10~12 water vapor conversion

[0078] With the residual gas after separating carbon dioxide and hydrogen in embodiment 7, concrete composition is H 2 (46%)CO 2 (50%), CO (4%) enters the water vapor shift module, where CO and H 2 The ratio of the amount of substance of O is 1:6. See 3 for its working conditions and effects

[0079] table 3

[0080]

[0081] a CO conversion rate = (C 反应后的CO浓度 / C 反应前的CO浓度 )×100

Embodiment 13~15

[0082] Embodiment 13~15 carbon dioxide separation

[0083] The mixed gas composition after water vapor shift in embodiment 10 is H 2 (47.3%)CO 2

[0084] (51.2%), the gas of CO (1.4%) carries out carbon dioxide separation, and its working condition and effect are shown in Table 4.

[0085]Table 4

[0086]

[0087] a: Carbon dioxide separation efficiency = (n 分离后的物质的量 / n 分离前的物质的量 )×100

[0088] The concentration of the obtained carbon dioxide after separation>98.5%, can be directly used in carbon dioxide hydrogenation to synthesize methanol, and the remaining gas, such as shown in Example 15, wherein H 2 , CO 2 The composition of CO and CO is close to the composition of the methanol reformed mixed gas in Example 1, and can be directly returned to the palladium membrane for cyclic separation.

[0089] It can be seen from Table 1, Table 2, Table 3 and Table 4 that hydrogen for fuel cells can be efficiently produced by solar fuel methanol reforming. At the same time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com