Composite scale and corrosion inhibitor suitable for low-hardness water and application thereof

A scale and corrosion inhibitor, hard water technology, applied in natural water treatment, non-polluted water treatment, descaling and water softening, etc., can solve the problem of scaling and corrosion of cooling facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

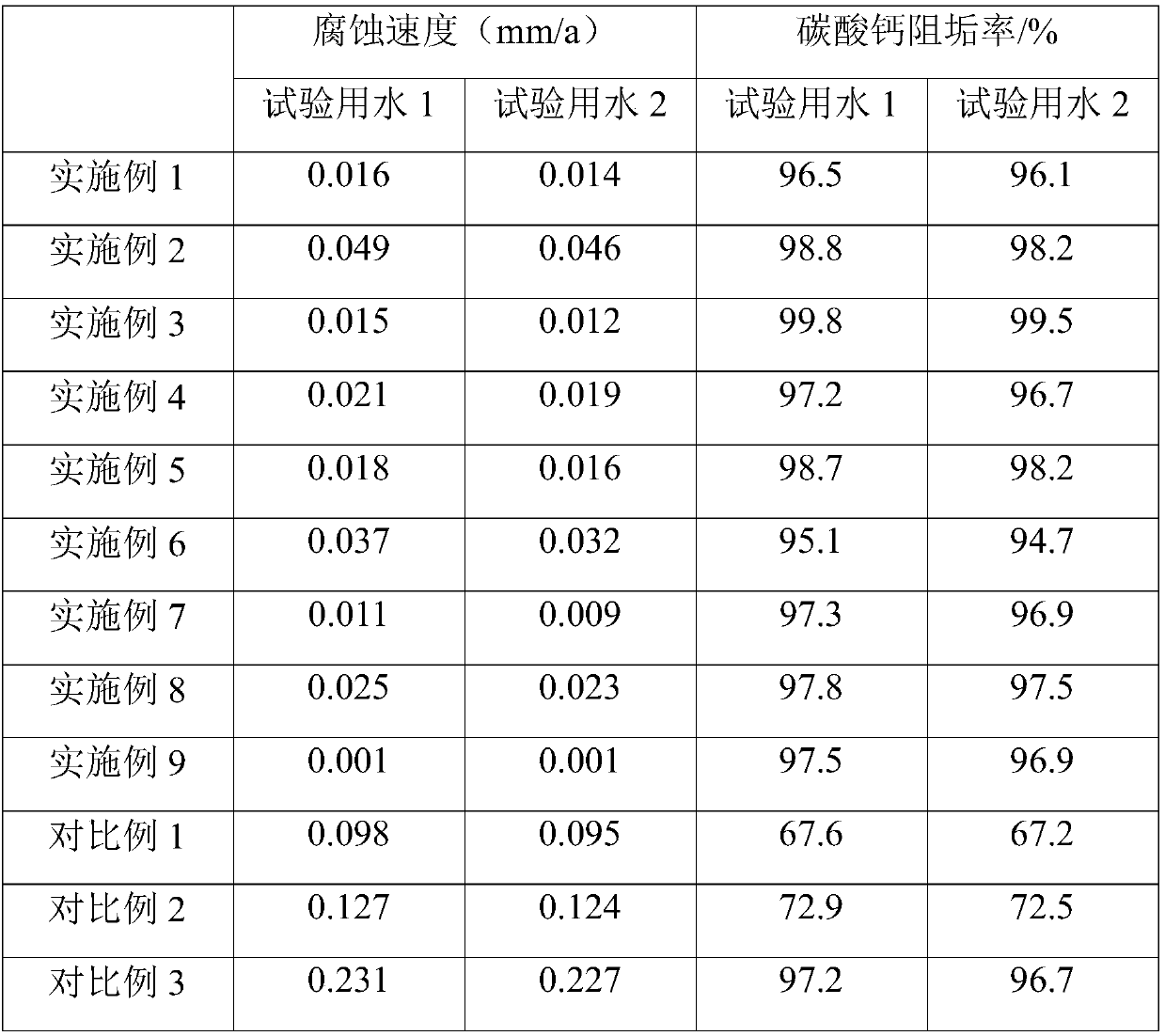

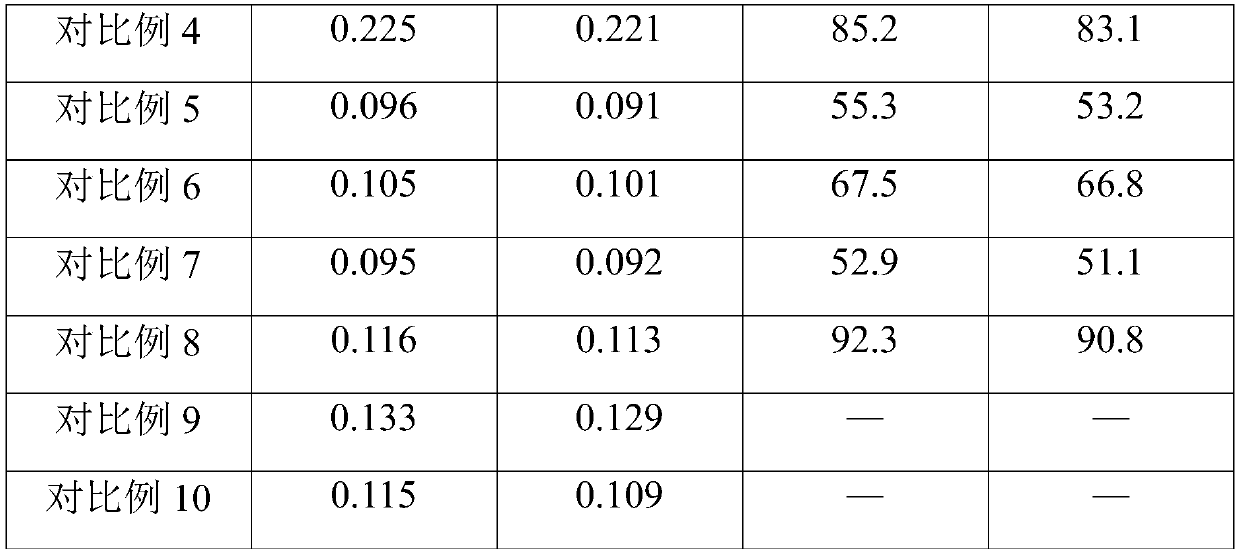

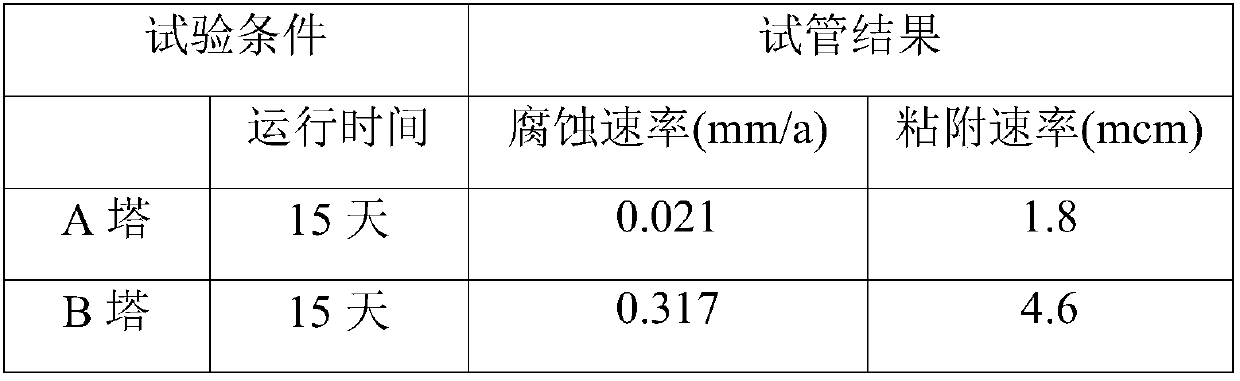

Examples

preparation example 1

[0059] Preparation of Condensation Reaction Product of Sodium Gluconate and Aspartic Acid

[0060] Add sodium gluconate (purchased from Bailingwei Technology Co., Ltd., analytically pure) 21.8g (0.1mol), aspartic acid (purchased from Aladdin Reagent (Shanghai) Co., Ltd., analytically pure) 26.6g (0.2mol) and 100mL water, start stirring to fully dissolve and mix sodium gluconate and aspartic acid, and then add concentrated sulfuric acid (purchased from Tianjin Guangfu Fine Chemicals) at room temperature (20°C) Institute, analytically pure, concentration is 98% by weight) 15g (containing H 2 SO 4 0.15mol). The heating bath (heating medium is simethicone) built-in the aforementioned flask was heated up to 100°C, and reacted for 10 hours. During the reaction, the amount of steamed water was 30g, and the remaining liquid, that is, a solid content of 29.5% by weight, was sodium gluconate and sodium gluconate. The condensation reaction product of aspartic acid has been determined...

preparation example 2

[0062] Preparation of Condensation Reaction Product of Sodium Gluconate and Aspartic Acid

[0063] Add 10.9g (0.05mol) of sodium gluconate, 16.6g (0.125mol) of aspartic acid, and 100mL of water into a four-neck flask equipped with a stirrer, a distillation device, and a thermometer, and start stirring to make sodium gluconate and asparagus The acid was fully dissolved and mixed, and then at room temperature (20°C), 7.5 g of concentrated sulfuric acid (containing H 2 SO 4 , 0.075mol). The heating bath (heating medium is simethicone) that is built-in with aforementioned flask is heated up to 140 ℃, reacts for 6 hours, and the amount of steamed water in the reaction process is 45g, and remaining liquid is the sodium gluconate and the sodium gluconate that solid content is 26.3% by weight and sky. The condensation reaction product of aspartic acid has been determined to have a molecular weight distribution in the range of 311-426.

preparation example 3

[0065] Preparation of Condensation Reaction Product of Potassium Gluconate and Aspartic Acid

[0066] Add potassium gluconate (purchased from Bailingwei Technology Co., Ltd., analytically pure) 23.4g (0.1mol), aspartic acid 13.3g (0.1mol) and 100mL water into a four-necked flask equipped with a stirrer, a distillation device and a thermometer , start stirring, potassium gluconate and aspartic acid are fully dissolved and mixed, then add concentrated nitric acid (purchased from Beijing Yili Fine Chemical Research Institute, analytically pure, concentration is 68% by weight) 3.7g at room temperature (20°C) (with HNO 3 , 0.04mol). The heating bath (heating medium is simethicone) that is built-in with aforementioned flask is heated up to 180 ℃, reacts for 6 hours, and steaming water amount is 55g in the reaction process, and remaining liquid is that solid content is 41.7% by weight of potassium gluconate and sky. The condensation reaction product of aspartic acid has been determ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ultimate viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com