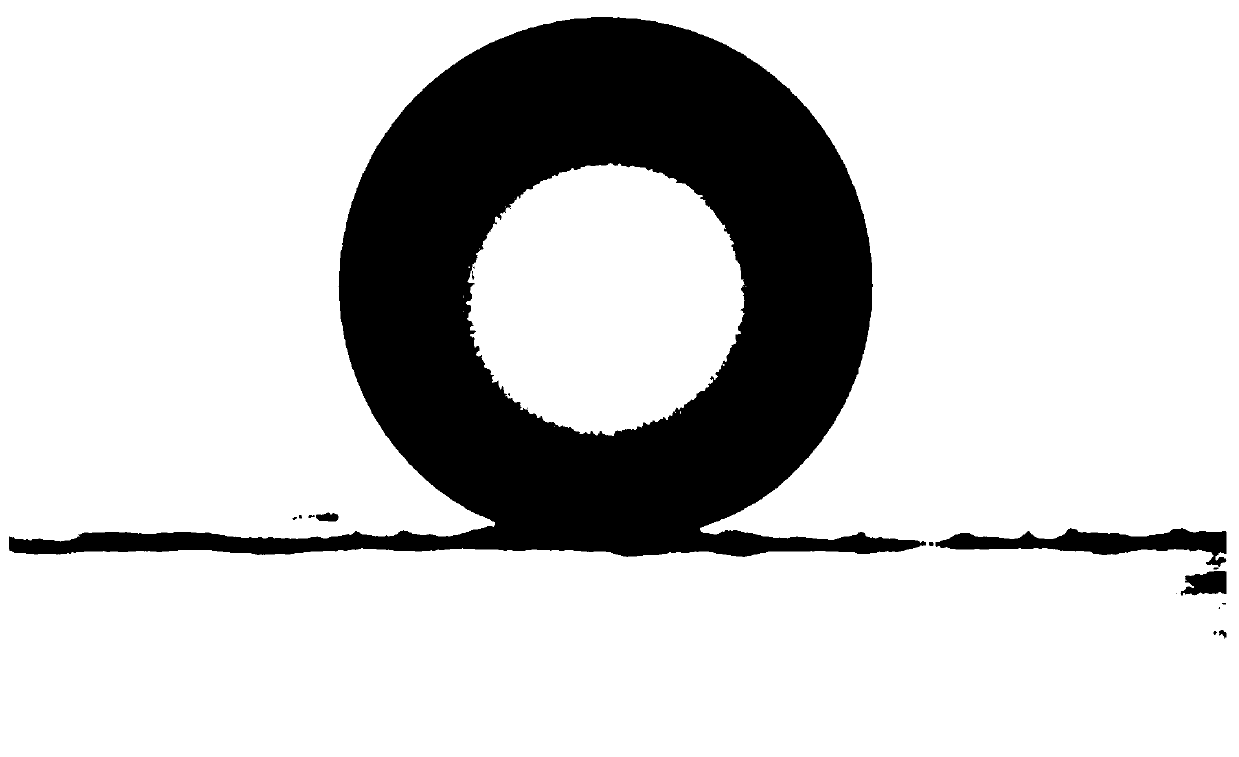

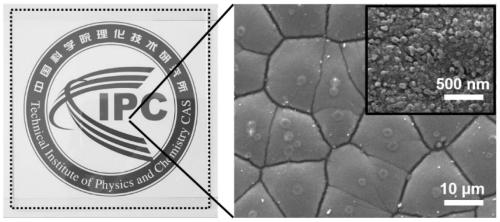

Underwater super-oleophobic material and preparation method thereof

An underwater super-oleophobic and super-hydrophilic technology, which is applied in general water supply saving, coating, etc., can solve the problems of inability to guarantee the transparency of materials, achieve excellent underwater super-oleophobicity, improve utilization rate, and easily obtain raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

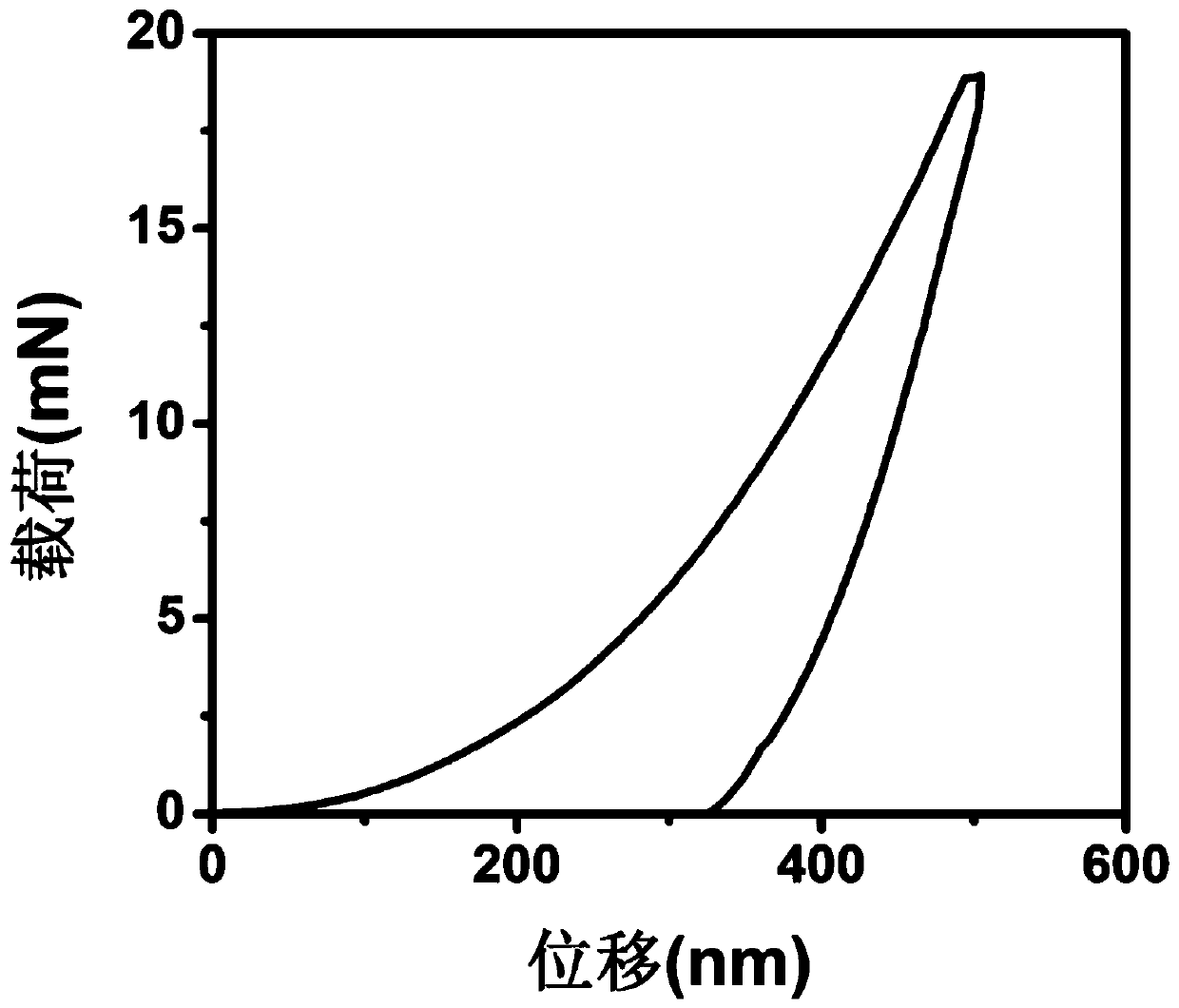

Method used

Image

Examples

Embodiment 1

[0050] (1) Dip the glass sheet (5×5cm) with deionized water 2 , d=1mm) ultrasonically cleaned for 30 minutes, dried in an oven at 40°C for 1 hour, and treated with a plasma cleaner in high power mode for 8 minutes;

[0051](2) Pre-prepared 1.0wt% chitosan is spin-coated on the above-mentioned glass sheet, and the rotating speed of the spin-coating is 5000rpm and kept for 1min, and put into an oven at 40° C. for 2 hours to dry after spin-coating;

[0052] (3) Prepare 25mM CaCl with deionized water 2 Aqueous solution 100mL, after stirring and dissolving at room temperature for 30min, then add 0.06g of polyacrylic acid (PAA), continue stirring and dissolving for 30min, then slowly add 25mM NaCO 3 100mL aqueous solution, continue stirring and mixing for 30min, adjust the pH of the mixed solution to 10.0 with 1.0mol / L sodium hydroxide aqueous solution, and obtain a polymer-coated ACC solution;

[0053] (4) Soak the above-mentioned modified glass piece in 25mL of ACC solution, and...

Embodiment 2

[0058] (1) Dip the glass sheet (5×5cm) with deionized water 2 , d=1mm) ultrasonically cleaned for 30 minutes, dried in an oven at 60°C for 1 hour, and treated with a plasma cleaner in high power mode for 8 minutes;

[0059] (2) Soak the above-mentioned glass sheet in a pre-prepared 5.0wt% polyacetimide solution (100mL), remove it after soaking for 30min, and put it into an oven at 60°C for 2 hours to dry;

[0060] (3) Prepare 20mM CaCl with deionized water 2 Aqueous solution 100ml, stir and dissolve at room temperature for 20min, then add 0.08g of polyaspartic acid (PASP), continue to stir and dissolve for 20min, then slowly add 20mM NaCO 3 100mL aqueous solution, continue to stir and mix for 20min, adjust the pH of the mixed solution to 11.0 with 1.0mol / L sodium hydroxide aqueous solution, and obtain a polymer-coated ACC solution;

[0061] (4) Soak the above-mentioned modified glass piece in 30mL ACC solution, and put it in a water bath at 25°C for 6 hours for mineralizatio...

Embodiment 3

[0063] (1) Polyethylene terephthalate sheet (PET) (5×5cm 2 , d=5mm) ultrasonically cleaned for 30 minutes, dried in an oven at 60°C for 1 hour, and treated with a plasma cleaner in high power mode for 12 minutes;

[0064] (2) Spray-coat pre-prepared 6.0wt% polylysine evenly on the above-mentioned PET sheet, the temperature of the sprayed base is controlled at 60°C, and the sprayed PET is put into an oven at 60°C for 2 hours for further drying;

[0065] (3) Prepare 28mM CaCl with deionized water 2 Aqueous solution 100mL, after stirring and dissolving at room temperature for 30min, then add 0.06g of polyacrylic acid (PAA), continue stirring and dissolving for 30min, then slowly add 28mM NaCO 3 100mL aqueous solution, continue to stir and mix for 30min, adjust the pH of the mixed solution to 13.0 with 1.0mol / L sodium hydroxide aqueous solution, and obtain a polymer-coated ACC solution;

[0066] (4) Soak the above-mentioned modified glass piece in 50mL ACC solution, and put it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com