Organic compound and electronic device

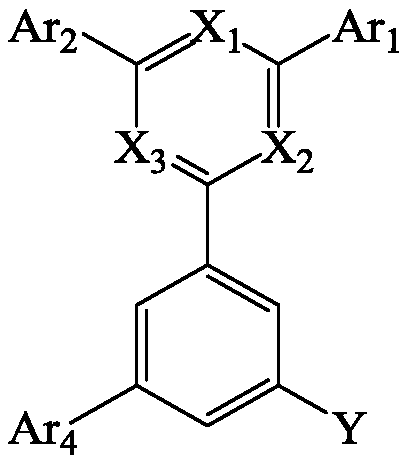

A technology of organic compounds and electronic devices, applied in organic chemistry, chemical instruments and methods, circuits, etc., can solve the problems of performance degradation, luminous efficiency reduction, driving voltage increase of light-emitting devices, etc., to improve life characteristics, enhance injection and transmission. , the effect of inhibiting material crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The preparation method of the compound of the embodiment of the present invention is described in detail below:

[0064] Synthesis of compound 1

[0065]

[0066] Magnesium strips (15.44g, 643.5mmol) and diethyl ether (100mL) were placed in a dry round bottom flask under nitrogen, and iodine (119mg) was added. Then a solution of ether (200mL) dissolved with 2-bromobiphenyl 2-bromotoluene (50.00g, 214.49mmol) was slowly dropped into the flask, and after the addition was completed, the temperature was raised to 35°C and stirred for 3 hours; the reaction solution was lowered to 0°C, a solution of ether (200mL) dissolved with adamantanone (48.33g, 321.7mmol) was slowly dropped into it, and after the addition was completed, the temperature was raised to 35°C and stirred for 6 hours; the reaction solution was cooled to room temperature, and added 5% hydrochloric acid to pH<7, stirred for 1 hour, added diethyl ether (200mL) for extraction, combined the organic phases, drie...

Embodiment 1

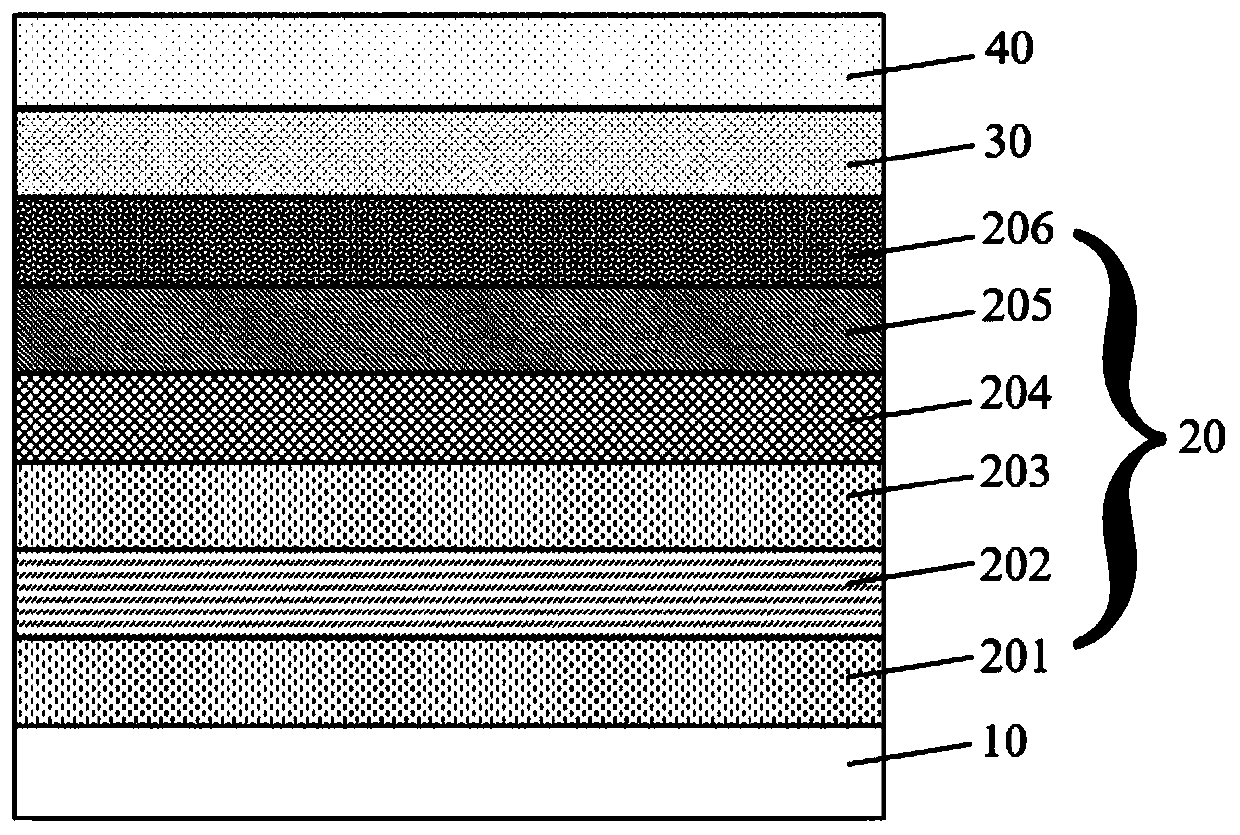

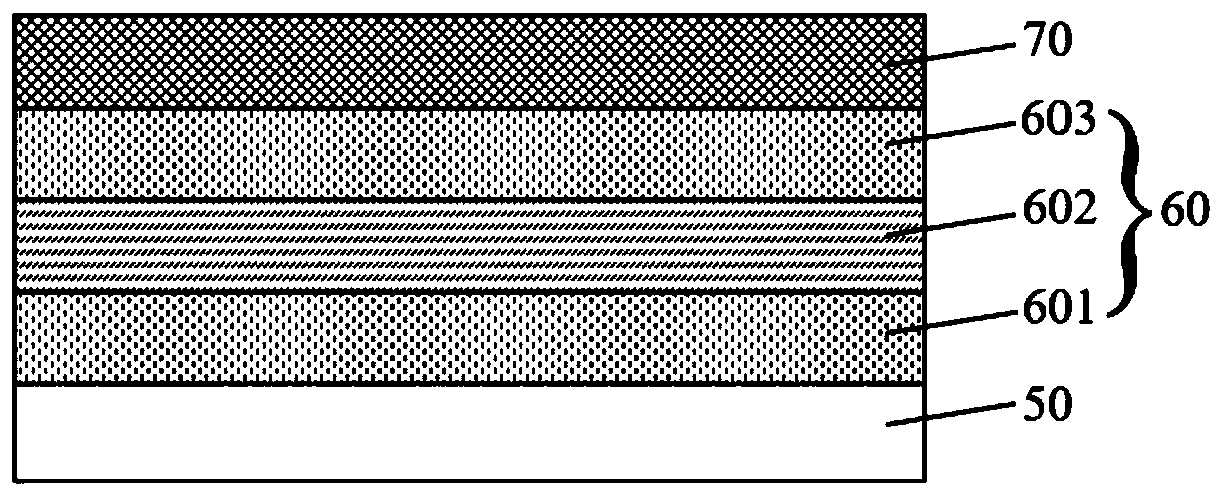

[0183] The anode 10 is prepared by the following process: the thickness is The ITO substrate was cut into a size of 40mm × 40mm × 0.7mm, and it was prepared into a top emission experimental substrate with a cathode overlapping area, an anode and an insulating layer pattern by using a photolithography process, using ultraviolet ozone and O 2 :N 2 Plasma is used for surface treatment to increase the work function of the anode (experimental substrate) and to clean the experimental substrate.

[0184] On the experimental substrate (anode 10) vacuum evaporation HAT-CN to form a thickness of The hole injection layer (HIL) 201.

[0185] NPB is vacuum evaporated on the hole injection layer 201 to form a thickness of The hole transport layer (HTL) 202.

[0186] Evaporate TCTA on the hole transport layer 202 to form a thickness of Electron blocking layer (EBL) 203 .

[0187] α, β-ADN is used as the main body, and BD-1 is doped at a doping ratio of 3%, and evaporated on the ele...

Embodiment 2-19

[0197] The organic electroluminescence device was fabricated by the same method as in Example 1, except that, when forming the electron transport layer (ETL) 206, the compounds shown in Table 1 were used instead of Compound 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap