Aging-resistant flame-retardant cable and processing technology

A processing technology, flame retardant cable technology, applied in power cable, insulated cable, cable/conductor manufacturing and other directions, can solve the problems of poor aging resistance, difficult to meet the high standard requirements of cables, etc. performance, avoid the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

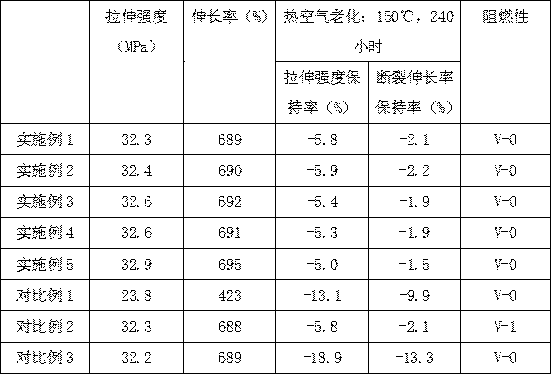

Examples

Embodiment 1

[0034] A processing technology for aging-resistant flame-retardant cables. First, multiple wires are twisted into bundles and wrapped around the cladding and insulating layers on the outside to obtain wire cores, and then multiple groups of wire cores are arranged in bundles to form cable cores. The insulation layer and the sheath layer are wrapped in turn on the outside of the cable core to obtain the cable, wherein the sheath layer is prepared by the following method:

[0035](1) First mix 100kg methyl vinyl silicone rubber, 30kg EPDM rubber, 15kg thermoplastic polyester elastomer, 5kg carboxyl liquid nitrile rubber, 4kg structure control agent and 5kg organic modified filler with a kneader to obtain Mixture; the organically modified filler is coated with magnesium hydroxide on the surface of the ammonium polyphosphate-aluminum hydroxide-zinc borate compound, then the resulting product is mixed with ethyl naphthol, hexacyclite powder, silicon carbide fiber, and then the penta...

Embodiment 2

[0045] A processing technology for aging-resistant flame-retardant cables. First, multiple wires are twisted into bundles and wrapped around the cladding and insulating layers on the outside to obtain wire cores, and then multiple groups of wire cores are arranged in bundles to form cable cores. The insulation layer and the sheath layer are wrapped in turn on the outside of the cable core to obtain the cable, wherein the sheath layer is prepared by the following method:

[0046] (1) First mix 100kg methyl vinyl silicone rubber, 40kg EPDM rubber, 20kg thermoplastic polyester elastomer, 8kg carboxyl liquid nitrile rubber, 6kg structure control agent and 8kg organic modified filler with a kneader to obtain Mixture; the organically modified filler is coated with magnesium hydroxide on the surface of the ammonium polyphosphate-aluminum hydroxide-zinc borate compound, then the resulting product is mixed with ethyl naphthol, hexacyclite powder, silicon carbide fiber, and then the pent...

Embodiment 3

[0056] A processing technology for aging-resistant flame-retardant cables. First, multiple wires are twisted into bundles and wrapped around the cladding and insulating layers on the outside to obtain wire cores, and then multiple groups of wire cores are arranged in bundles to form cable cores. The insulation layer and the sheath layer are wrapped in turn on the outside of the cable core to obtain the cable, wherein the sheath layer is prepared by the following method:

[0057] (1) First mix 100kg methyl vinyl silicone rubber, 30kg EPDM rubber, 20kg thermoplastic polyester elastomer, 5kg carboxyl liquid nitrile rubber, 6kg structure control agent and 5kg organic modified filler with a kneader to obtain Mixture; the organically modified filler is coated with magnesium hydroxide on the surface of the ammonium polyphosphate-aluminum hydroxide-zinc borate compound, then the resulting product is mixed with ethyl naphthol, hexacyclite powder, silicon carbide fiber, and then the pent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com