Flame-retardant low-dielectric copper-clad plate and preparation method thereof

A technology of copper clad laminate and low dielectric, applied in the field of flame retardant low dielectric copper clad laminate and its preparation, can solve the problems of insufficient mechanical strength, poor adhesion of copper clad laminate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The preparation of unsaturated phosphorus-containing phenolic resin, implementation steps are as follows:

[0055] Dissolve 100 parts by mass of phosphorus-containing phenolic resin and 31 to 56 parts by mass of esterifying agent in 400 to 600 parts by mass of an organic solvent, add 7 to 68 parts by mass of a basic catalyst at 50 to 80°C for 2 to 3 hours, filter, Wash with water until neutral and remove the organic solvent to obtain the unsaturated phosphorus-containing phenolic curing agents of Examples 1-1 to 1-4.

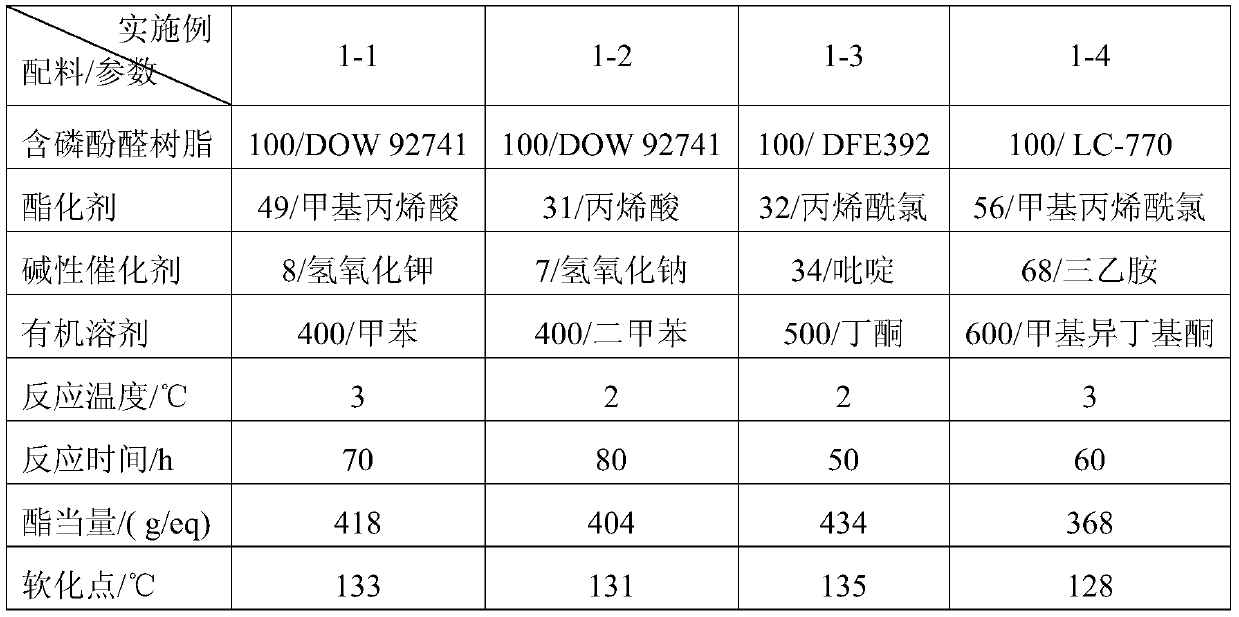

[0056] Table 1: List of ingredients and performance parameters of the unsaturated phosphorus-containing phenolic curing agent of Examples 1-1 to 1-5:

[0057]

[0058] Note in Table 1: DOW 92741, phosphorus-containing bisphenol A phenolic resin, hydroxyl equivalent 350g / eq; DFE392, phosphorus-containing bisphenol A phenolic resin, hydroxyl equivalent 380g / eq; LC-770, phosphorus-containing phenolic resin, hydroxyl equivalent 280~320g / eq, the unit of co...

Embodiment 2

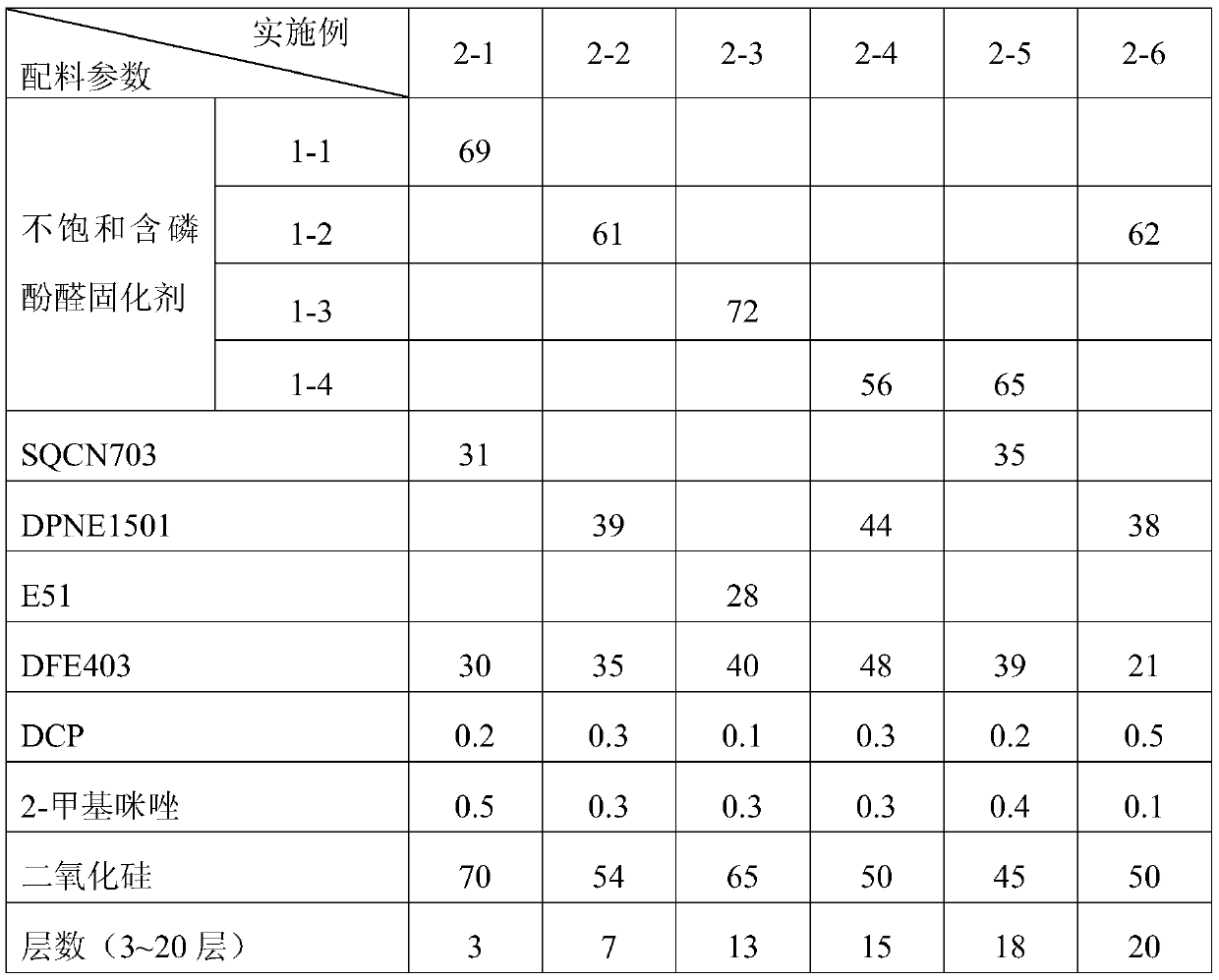

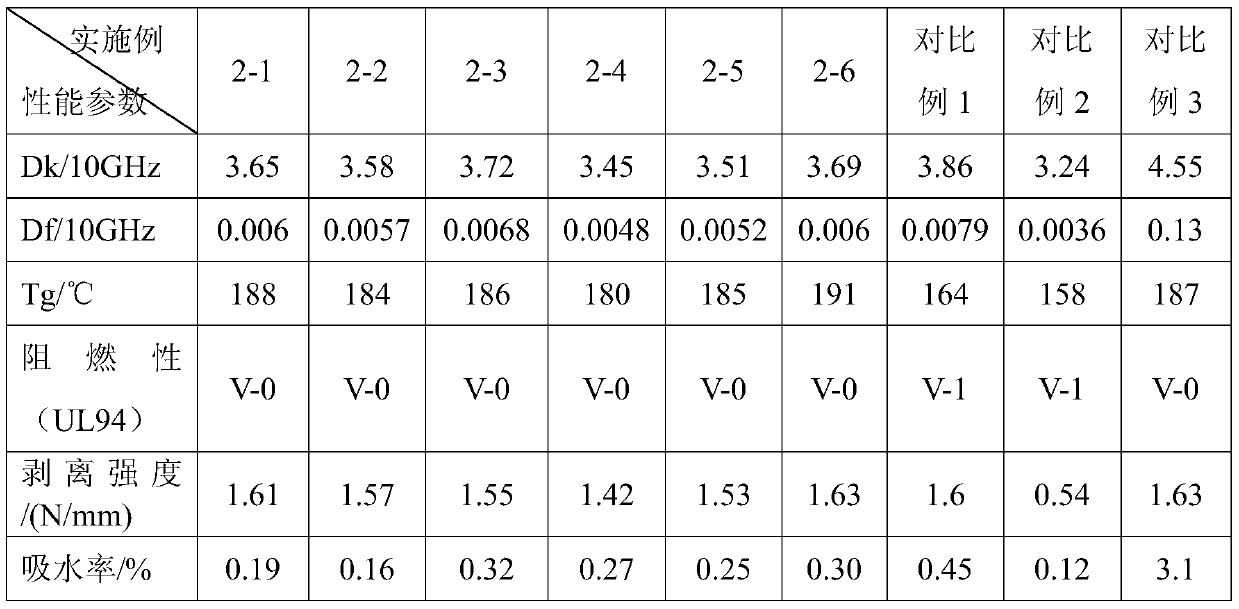

[0061] The preparation steps of flame-retardant low-dielectric copper-clad laminates are as follows:

[0062] (1) Prepare flame retardant thermosetting resin composition glue:

[0063] 28-44 parts by mass of epoxy resin, 56-72 parts by mass of unsaturated phosphorus-containing phenolic curing agent, 21-48 parts by mass of hydrocarbon resin, 0.1-0.5 parts by mass of accelerator, 0.1-0.5 parts by mass of initiator, 45- 70 parts by mass of the filler and an appropriate amount of solvent are uniformly mixed to prepare a glue solution of a flame-retardant thermosetting resin composition with a solid content of 60% to 70%.

[0064] (2) Preparation of flame retardant low dielectric copper clad laminate:

[0065] After impregnating the glass fiber cloth in the tank containing the glue solution of the flame-retardant thermosetting resin composition described in step 2, remove most of the solvent A through a drying tunnel at 50°C to 100°C, and then bake at 130°C to 170°C for 4 ~7min t...

Embodiment 3

[0087] A flame-retardant low-dielectric copper-clad laminate, the flame-retardant low-dielectric copper-clad laminate consists of 28 parts by mass of epoxy resin, 56 parts by mass of unsaturated phosphorus-containing phenolic curing agent, 21 parts by mass of hydrocarbon resin, 0.1 part by mass of accelerator, A flame retardant thermosetting resin composition consisting of 0.1 parts by mass of initiator, 45 parts by mass of filler, uniformly mixed with (appropriate amount) solvent A to make a resin solution, impregnated glass fiber cloth, and then removed most of the solvent A through a 50°C drying tunnel , and then bake the impregnated glass fiber cloth at a temperature of 130°C for 7 minutes to make a prepreg, then stack the three-layer prepreg with copper foil on both sides, and cure it in a hot press.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com